Cleaning device used for electrostatic spraying equipment

A cleaning device and electrostatic spraying technology, applied in the direction of the spraying device, etc., can solve the problems of electrostatic spray gun nozzle clogging and unfavorable spraying work, etc., and achieve the effect of realizing cleaning work, reliable and comprehensive cleaning effect, and avoiding clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

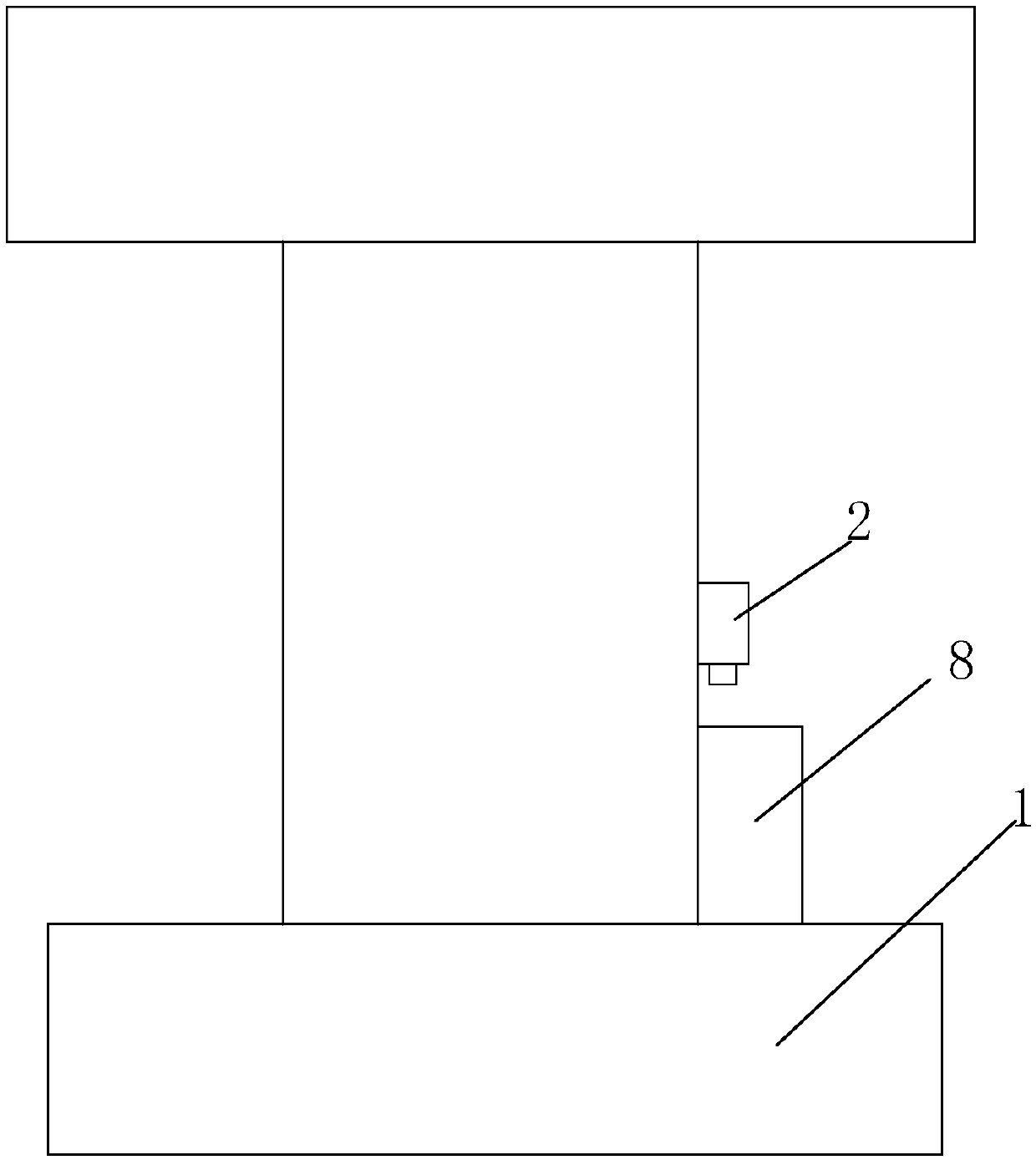

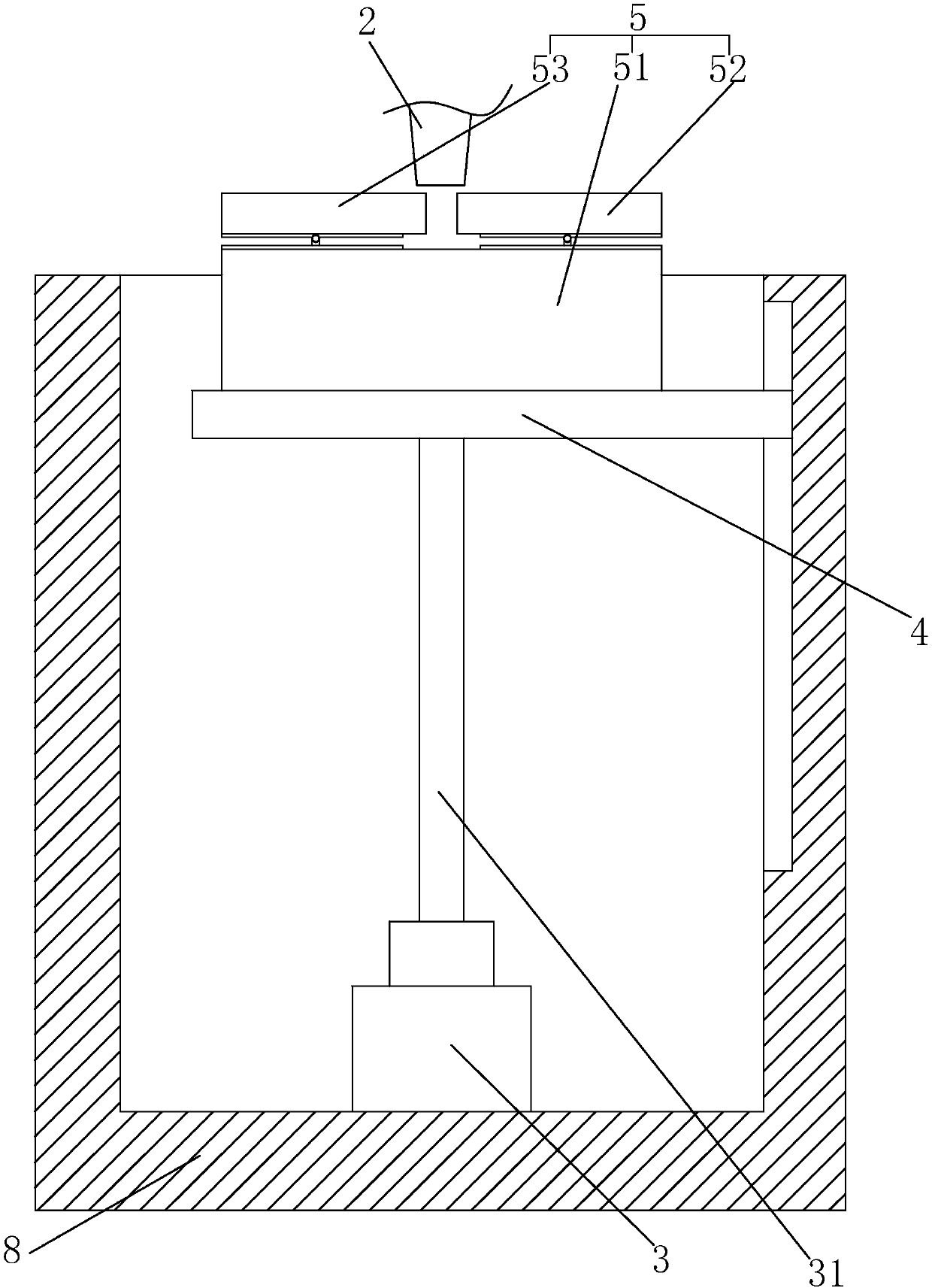

[0020] Embodiment 1: a kind of cleaning device used in electrostatic spraying equipment, such as figure 1 As shown, including the body 1 and the electrostatic spray gun 2 hung on the body 1, the cleaning device includes a cleaning bucket 8 fixedly arranged on the body 1 and directly below the electrostatic spray gun 2, as figure 2 As shown, the bottom in the cleaning bucket 8 is fixedly provided with a driving motor 3, the output shaft of the driving motor 3 is connected and fixed with the working screw 31, and a cleaning rod 4 is threaded on the working screw 31, and one end of the cleaning rod 4 slides and buckles Embedded on the inner wall of the cleaning bucket 8, and on the upper surface of the cleaning rod 4, a cleaning cotton group 5 is fixed. The cleaning cotton group 5 includes the first cleaning cotton 51 connected and fixed with the cleaning rod 4. The first cleaning cotton 51 extends along its The second cleaning cotton 52 and the third cleaning cotton 53 are resp...

Embodiment 2

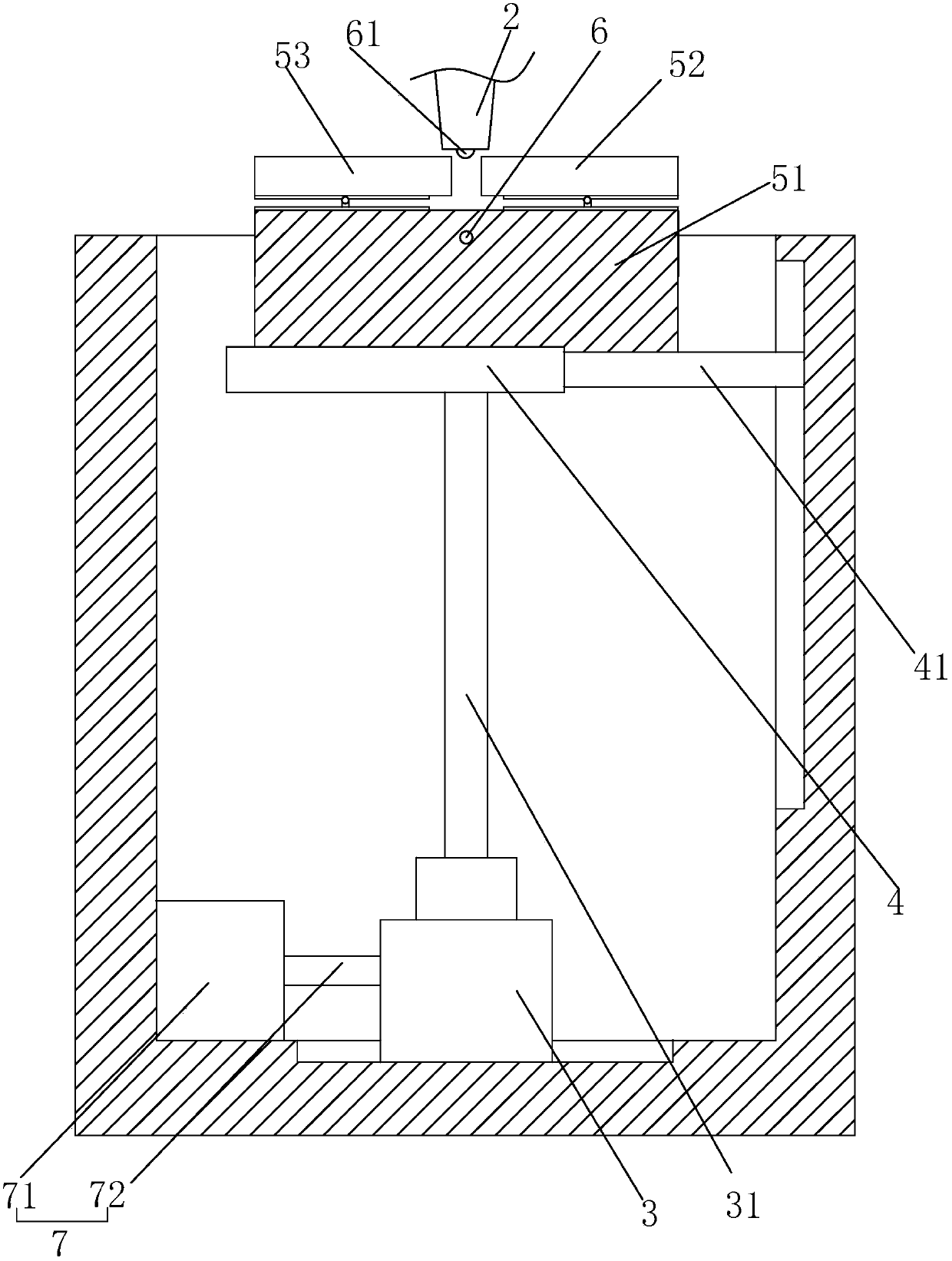

[0022] Embodiment 2: a cleaning device used in electrostatic spraying equipment, the difference from embodiment 1 is that, as image 3 As shown, at this time, an ultraviolet emitter 6 is arranged at the middle position inside the first cleaning cotton 51, and an ultraviolet receiver 61 is fixedly arranged at the nozzle of the electrostatic spray gun 2, and the drive motor 3 is then slidably arranged on the cleaning bucket. 8, and a position control mechanism 7 that controls the displacement of the drive motor 3 is provided at the bottom of the cleaning bucket 8. At the same time, a telescopic rod 41 is provided for sliding inside one end of the cleaning rod 4, and the telescopic rod 41 slides the buckle Embedded on the inner wall of the cleaning bucket 8, so as to match the displacement of the driving motor 3; the position control mechanism 7 includes a driving cylinder 71 fixedly arranged at the bottom of the cleaning bucket 8, and the piston rod 72 is connected and fixed with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com