Capsule screening and counting integrated device

A technology of counting device and capsule, applied in the direction of counting objects, counting mechanisms/items, and items shipped through conveying devices, etc., can solve problems such as inaccuracy, impact on the reputation of capsule manufacturers, loss of consumers, etc., to ensure accurate sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

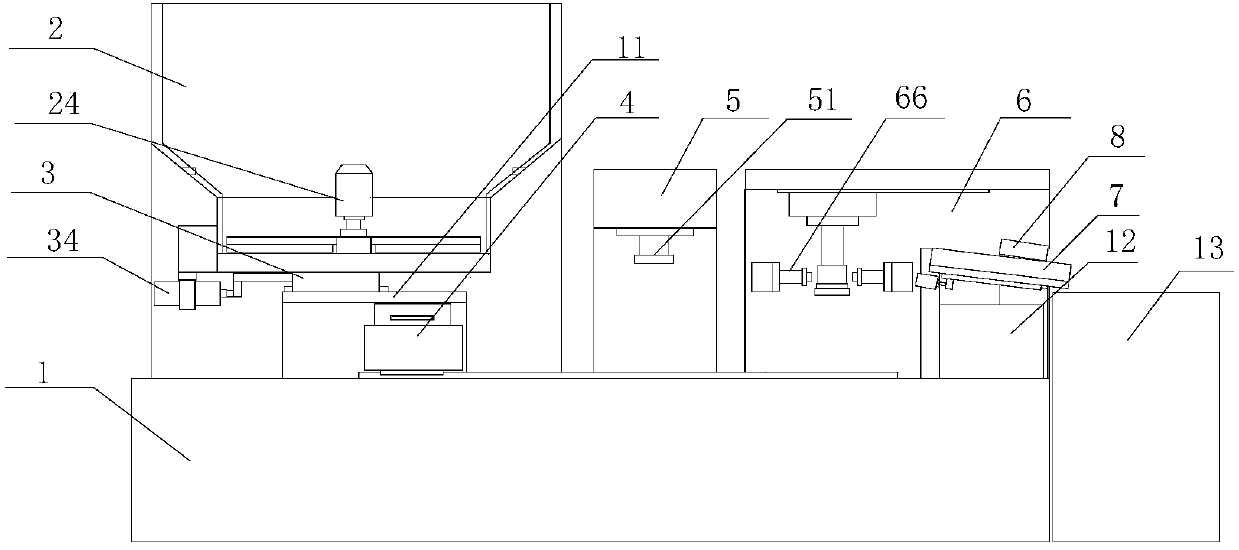

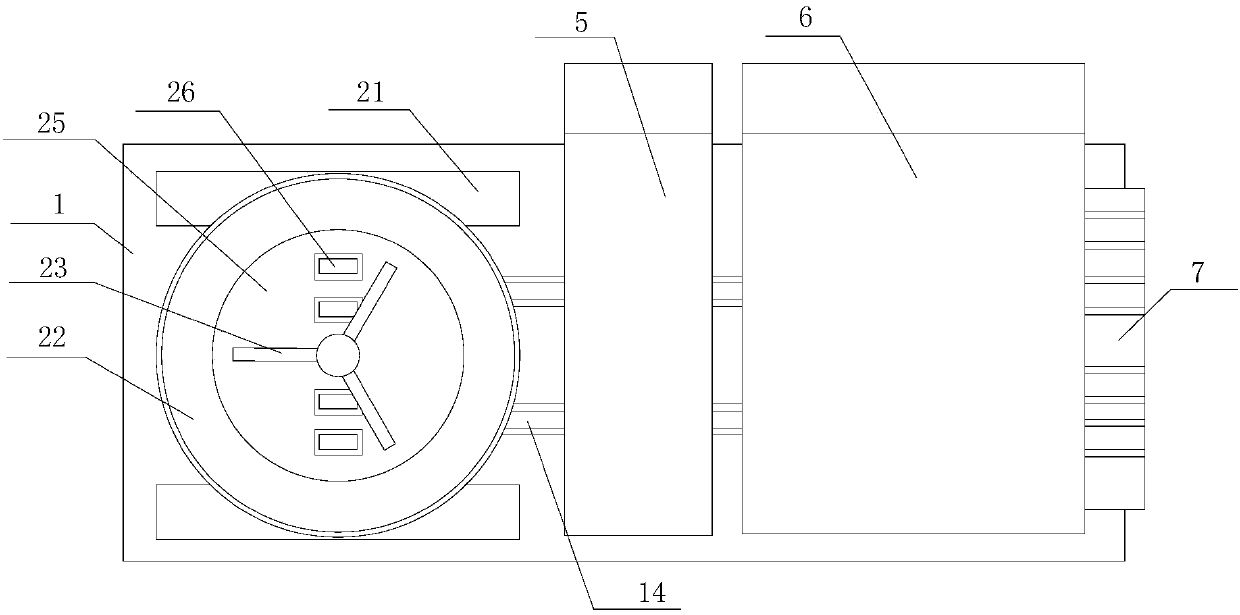

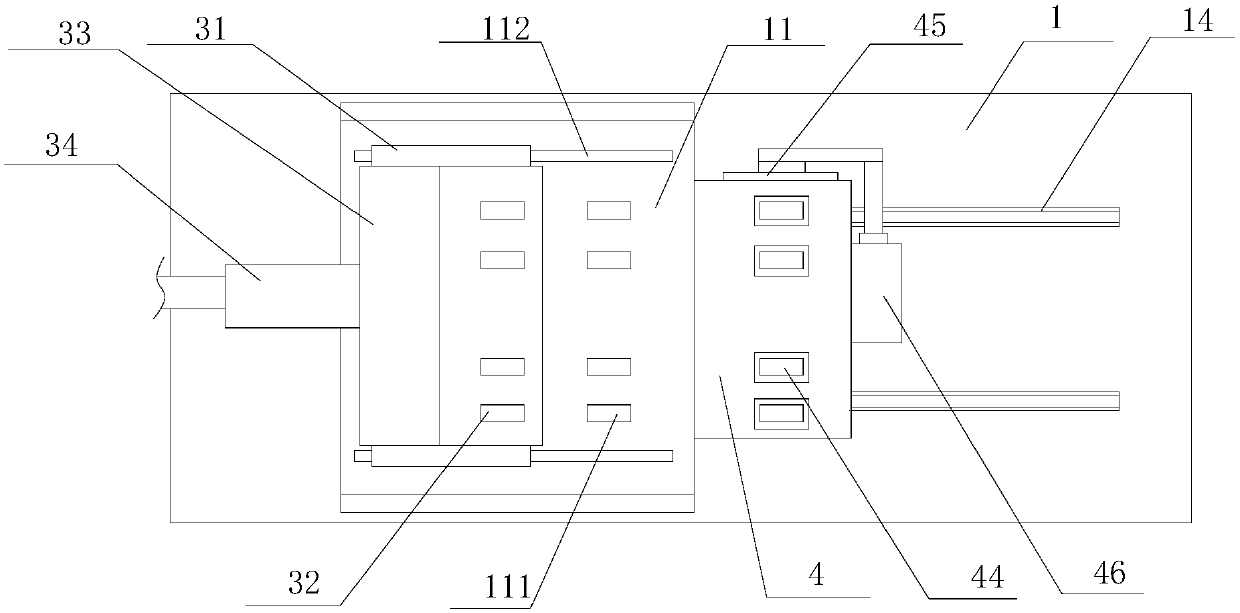

[0018] see Figure 1 to Figure 6, the present invention is an integrated device for screening and counting capsules, comprising a frame 1, a material storage mechanism 2, a feeding mechanism 3, a feeding mechanism 4, a circumferential detection device 5, an end detection device 6, a counting device 7 and a rejection mechanism 8, A storage mechanism 2 is installed on the rack 1, and a plurality of first blanking grooves 26 are opened below the storage mechanism 2. The rack 1 is provided with an auxiliary support seat 11. The auxiliary support seat A first guide rail 112 is arranged above the 11, and the feeding mechanism 3 is movably installed on the first guide rail 112. The auxiliary support base 11 is provided with a number of second blanking grooves 111. A number of third blanking troughs 32 are opened, and the third blanking troughs 32 are matched with the first blanking trough 26 and the second blanking trough 111. The frame 1 is provided with a second guide rail 14, so ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com