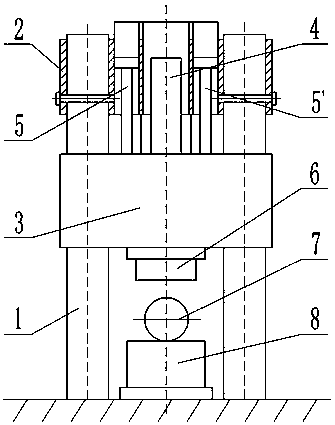

Multi-cylinder hydraulic forging machine and combined distribution of cylinders

A hydraulic cylinder and forging machine technology, applied in the field of hydraulic cylinder arrangement and hydraulic forging machine, can solve problems such as energy loss, achieve the effects of reducing energy loss, unique design ideas, and fast pressure building speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

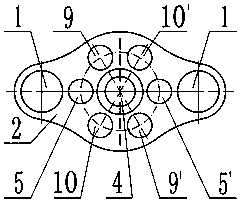

[0034] When the three groups of side hydraulic cylinders 5, 5' and 9, 9' and 10, 10' are evenly distributed on the circle centered on the central axis of the main hydraulic cylinder 4, and the three groups of side hydraulic cylinders 5, 5' and 9, 9 When the output pressure of ' and 10, 10' are the same, the combination is as follows:

[0035] a. Select a hydraulic cylinder as the pressure cylinder for pressing down, and select the main hydraulic cylinder 4 as the working pressure cylinder;

[0036] b. Select two hydraulic cylinders as pressure cylinders for pressing down, and the option is any group of side hydraulic cylinders (such as: 5, 5' or 9, 9' or 10, 10');

[0037]c. Select three hydraulic cylinders as pressure cylinders for pressing down. Option 1 is to select any group of side hydraulic cylinders (such as: 5, 5' or 9, 9' or 10, 10') to combine with the main hydraulic cylinder 4, Option two is three side hydraulic cylinders whose central axis forms a regular triangul...

Embodiment 2

[0043] When the three groups of side hydraulic cylinders 5, 5' and 9, 9' and 10, 10' are randomly distributed on different circles with the central axis of the main hydraulic cylinder 4 as the center, and the three groups of side hydraulic cylinders 5, 5' and 9, When the output pressure of 9' and 10, 10' is different, the combination is as follows:

[0044] a. Select a hydraulic cylinder as the pressure cylinder for pressing down, and select the main hydraulic cylinder 4 as the working pressure cylinder;

[0045] b. Select two hydraulic cylinders as the pressure cylinders for pressing down, and the option is a group of side hydraulic cylinders (such as: 5, 5' or 9, 9' or 10, 10');

[0046] c. Select three hydraulic cylinders as the pressure cylinders for pressing down. The option is to select any group of side hydraulic cylinders (such as: 5, 5' or 9, 9' or 10, 10') to combine with the main hydraulic cylinder 4;

[0047] d. Select four hydraulic cylinders as the pressure cyli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com