Automatic assembling machine for commutator assemblies

A commutator and assembly machine technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve problems such as easy bending of shafts, affecting assembly quality, affecting assembly efficiency, etc., to reduce labor intensity and improve assembly efficiency. and quality effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

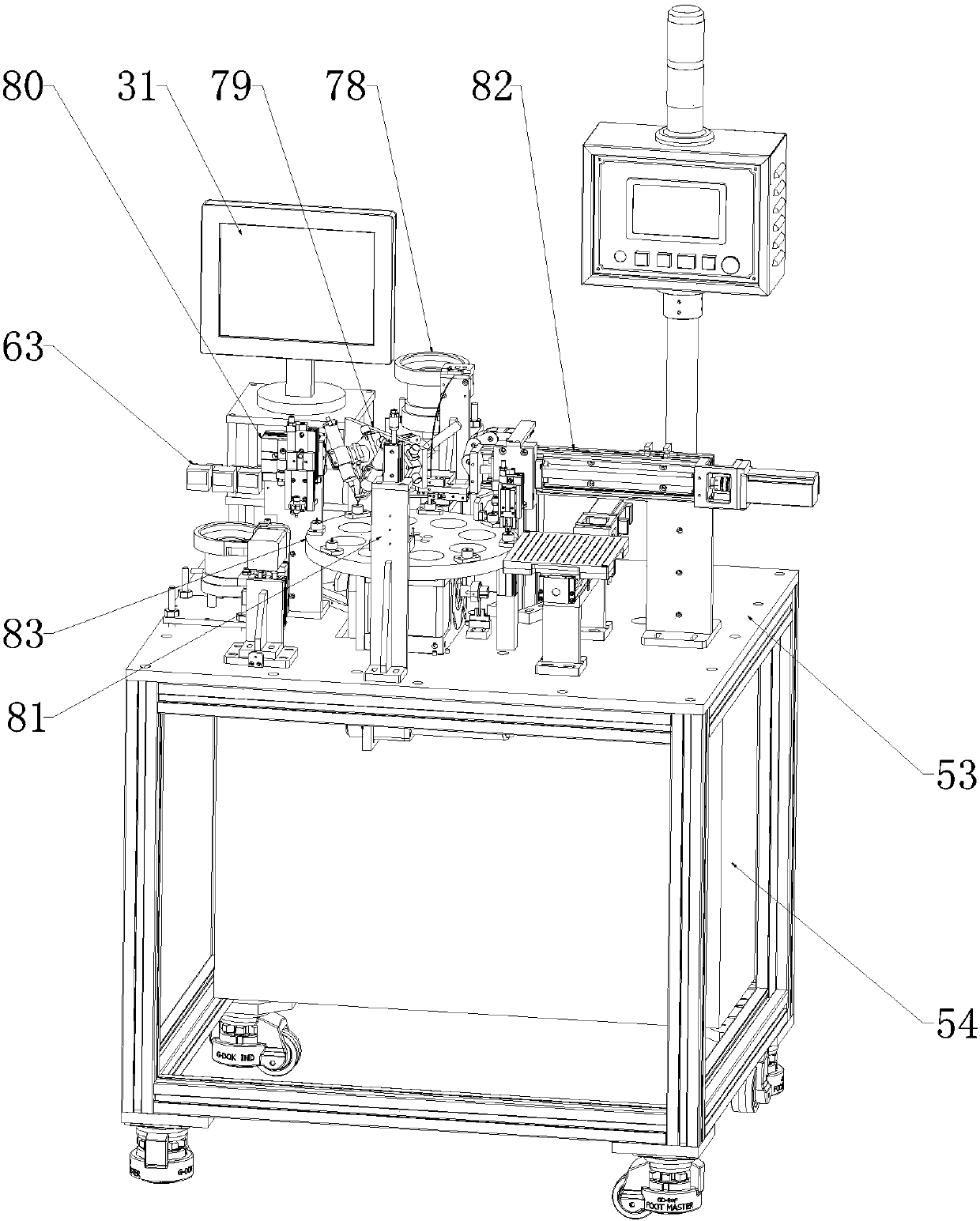

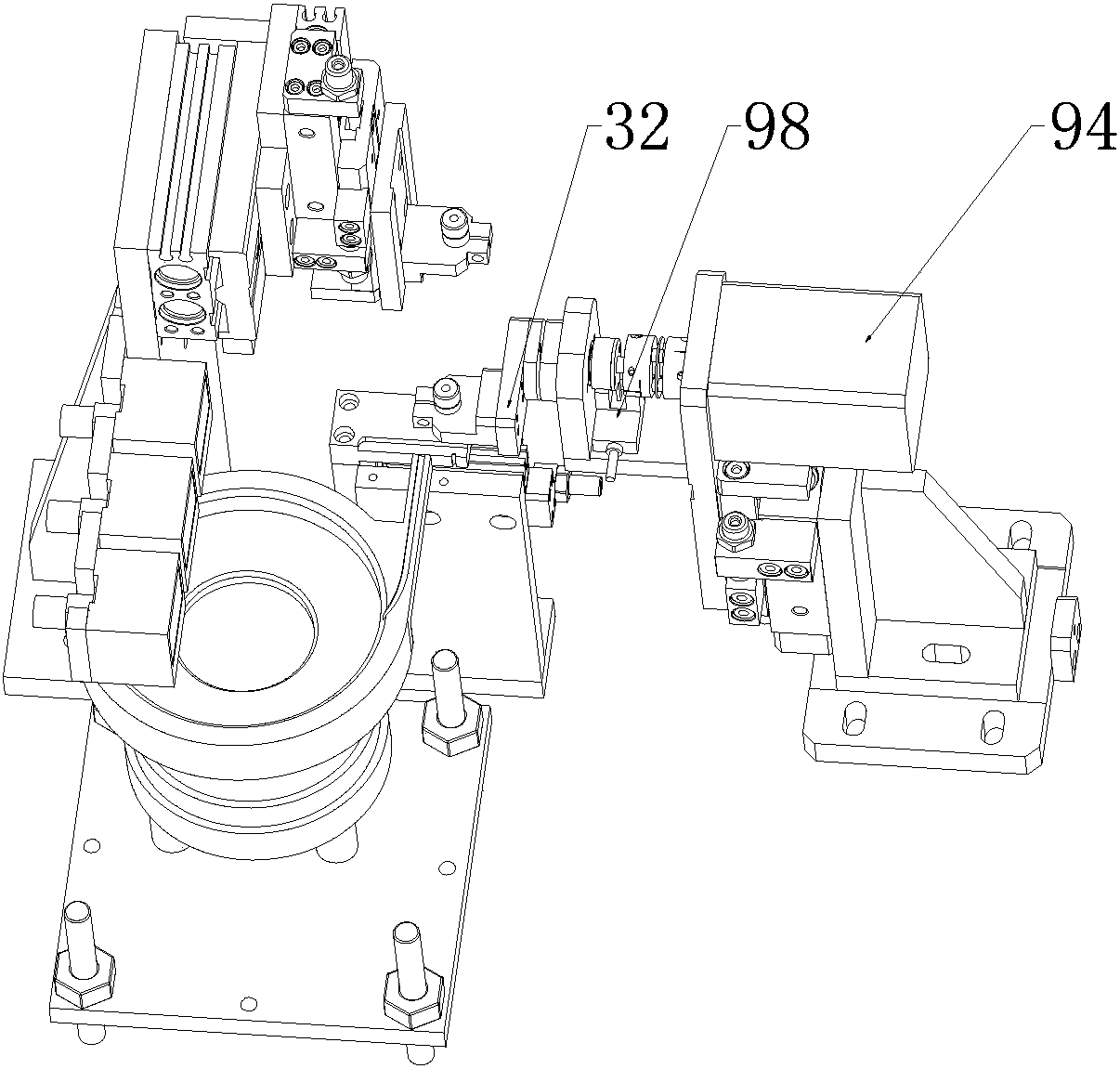

[0072] Such as Figure 1 to Figure 22 As shown, an automatic assembly machine for a commutator assembly includes a turntable assembly and a shaft loading assembly, a shaft dispensing assembly, a commutator feeding assembly, a riveting assembly, and a blanking assembly that are sequentially arranged along the rotation direction of the turntable assembly;

[0073] The turntable assembly includes a turntable 1 and a first drive device 2 for driving the turntable 1 to rotate, and the turntable 1 is provided with several circularly arranged positioning seat assemblies;

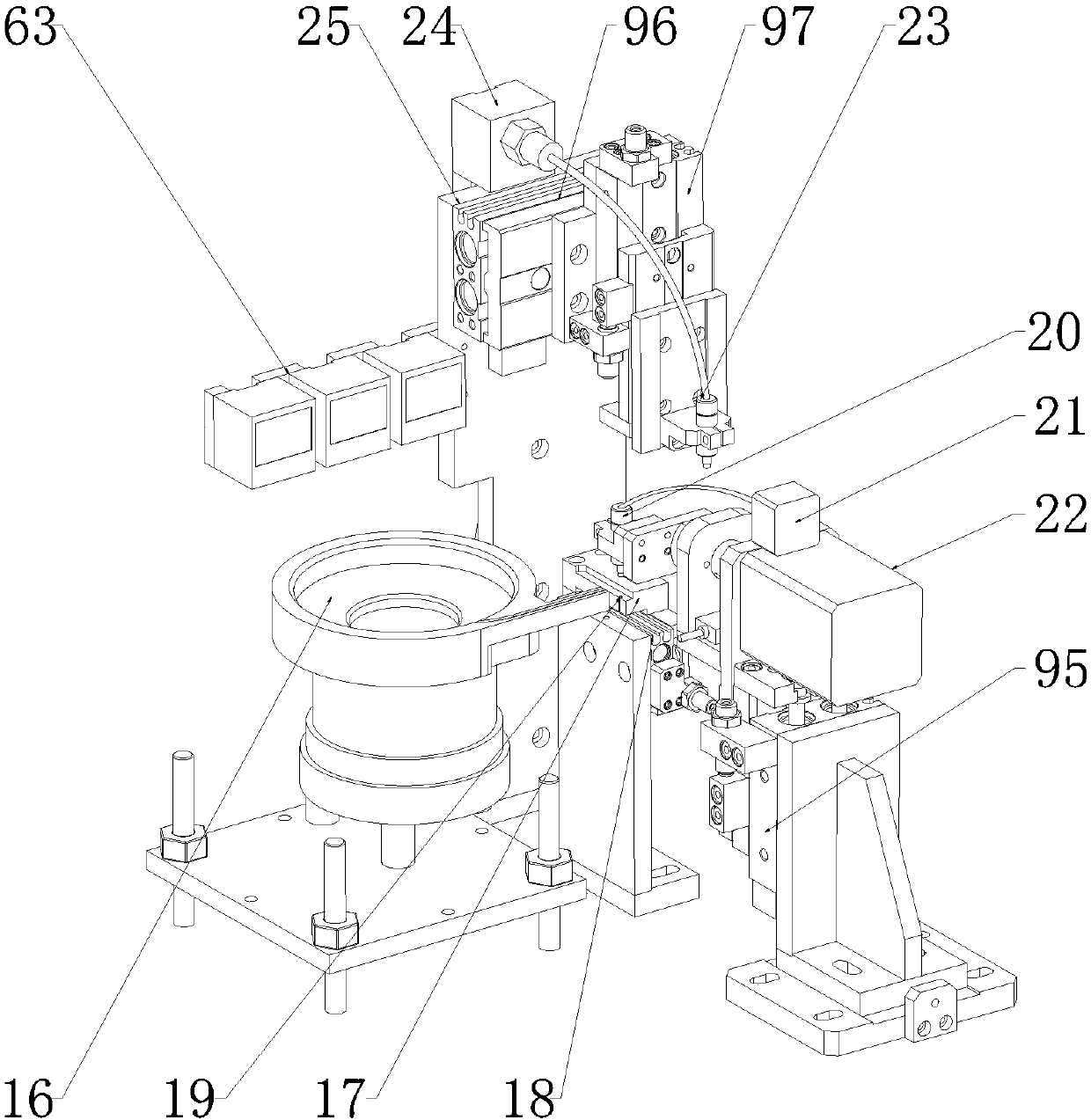

[0074] The on-shaft material correction assembly includes a first vibrating plate 3, an input assembly communicating with the first vibrating plate 3, an output assembly located above the turntable 1, and a blowing capillary 13 for connecting the input assembly and the output assembly;

[0075] The shaft dispensing assembly includes a dispensing assembly and an image collector located above the turntable 1, and the...

Embodiment 2

[0083] This embodiment makes the following further limitations on the basis of Embodiment 1: the input assembly includes a fixed block 4, a moving block 5 and a seventh driving device 6 for driving the moving block 5 to move up and down, and the fixed block 4 is provided with The inlet channel 7 communicated with the output end of the first vibrating plate 3, the fixed block 4 is also provided with an output channel 8 and an air inlet 9 communicated with the output channel 8, and the moving block 5 is provided with a through hole 10 provided through it. The input end of the hole 10 can be communicated with the inlet channel 7, and the output end of the through hole 10 can be communicated with the output channel 8;

[0084] The output assembly includes a fixed seat 11 located above the positioning seat assembly, the fixed seat 11 is provided with a connection hole 12 that runs through its upper and lower end faces, the input end of the blowing capillary 13 communicates with the ...

Embodiment 3

[0089] This embodiment makes the following further limitations on the basis of Embodiment 1: the image collector includes a super-eye camera 30 and a display 31 connected to the super-eye camera 30;

[0090] The first connecting member 14 is selected as the first fine-tuning translation platform;

[0091] There are two groups of dispensing components.

[0092] In this embodiment, the dispensing pen 15 in the two dispensing assemblies can be arranged obliquely, and should face both sides of the shaft. During application, glue dispensing pen 15 should link to each other with dispensing control machine by flexible pipe, like this, can provide the pneumatic power of dispensing pen 15. The first connecting piece 14 selects the first fine-tuning translation stage, either an XY-axis electric first fine-tuning translation stage, or an XY-axis manual first fine-tuning translation stage, so that the first fine-tuning translation stage can fine-tune two dimensions position on the

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com