Waterborne active direct-jet printing ink applicable to Kyocera inkjet print head

A printing ink and nozzle technology, applied in the field of water-based reactive direct-injection printing ink and its preparation, to achieve the effects of stable printing performance, good color reproduction, and prolonged service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

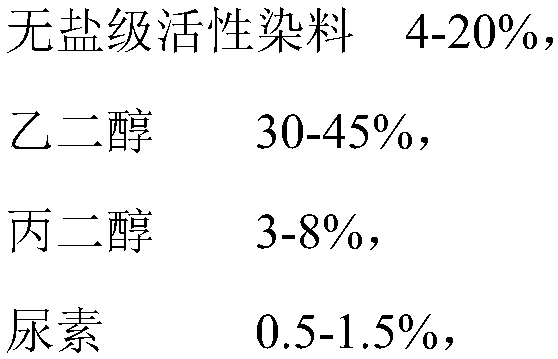

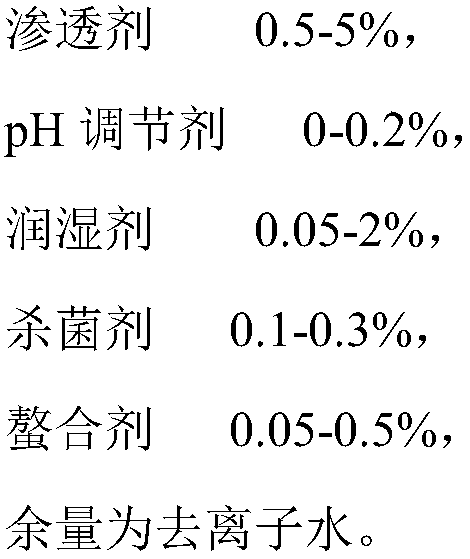

Method used

Image

Examples

Embodiment 1

[0032] A Kyocera water-based reactive direct jet printing ink, comprising the following raw materials by weight ratio: C.I.ReactiveBule1512.8%, ethylene glycol (EG) 35%, propylene glycol (PG) 5%, urea (UREA) 0.5%, Proxel GXL 0.1%, Tris base 0.1%, EDTA 0.1%, Surfynol 485 1%, Dynol 607 0.2%, EL-90 1.5%, the balance is deionized water.

[0033] The preparation method of the above-mentioned Kyocera water-based active direct jet printing ink comprises the following steps:

[0034] (1) take each raw material by weight ratio;

[0035] (2) Deionized water is heated to 40°C;

[0036] (3) Add propylene glycol, ethylene glycol, EL-90, Proxel GXL, Surfynol 485, Dynol 607, EDTA and Tris base to the deionized water in step (2) while stirring, and stir for 20 minutes at a stirring speed of 600 rpm Dissolve completely; add urea, continue to stir for 20 minutes until mixed evenly; then add C.I.Reactive Bule15, increase the stirring speed to 700rpm, stir for 50 minutes to mix evenly;

[0037...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com