Construction method of fully enclosed layer in core tube of super high-rise building

A construction method and core tube technology, which is applied in the direction of construction and building construction, can solve the problems of high safety requirements for vertical operations and long delays in the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to understand the technical content of the present invention more clearly, the following examples are given in detail.

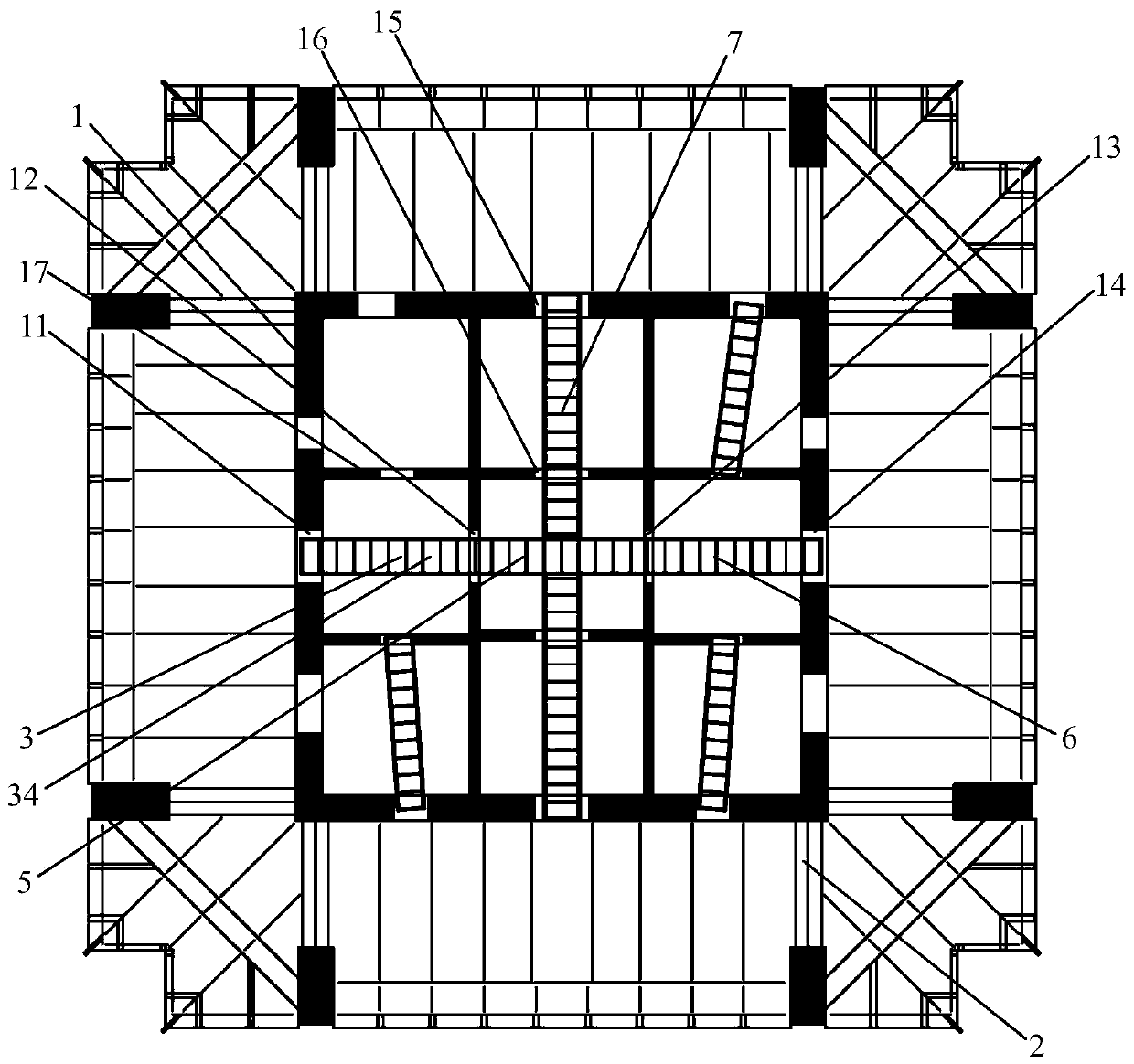

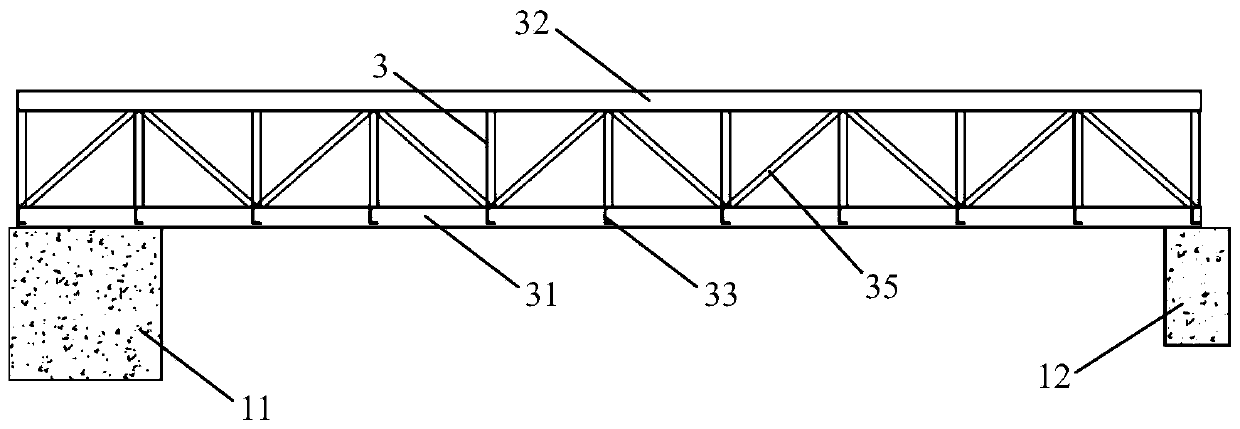

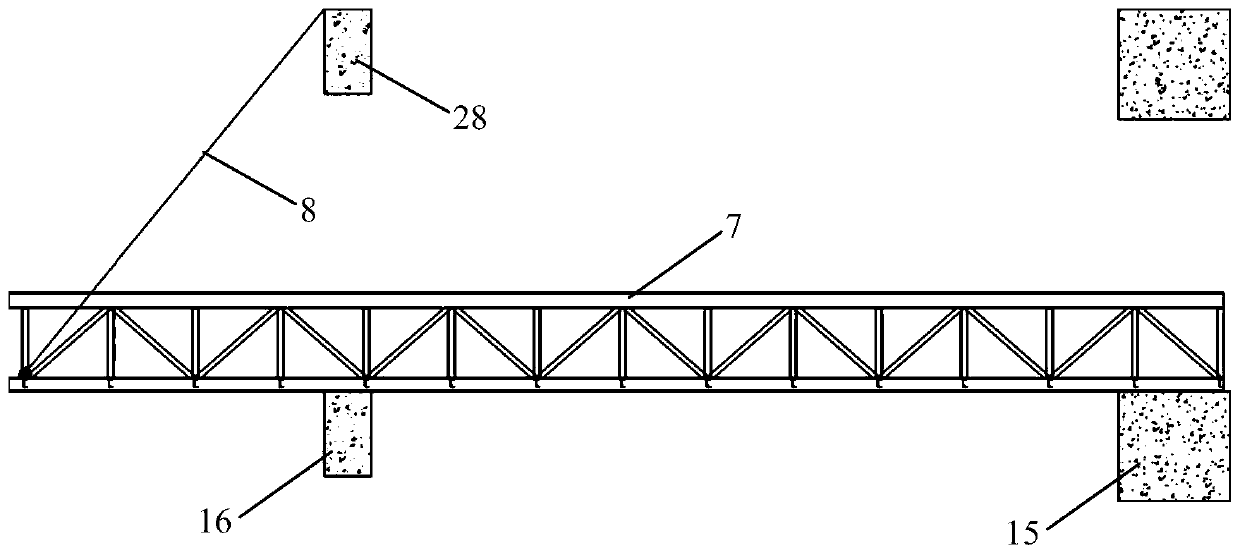

[0041] See Figure 1 ~ Figure 3B As shown, in a specific embodiment of the present invention, the fully enclosed layer construction method in the super high-rise building core tube of the present invention comprises the following steps:

[0042] (1) During the construction of the core tube of a super high-rise building, when the vertical wall 1 of the core tube exceeds the outer frame steel structure 2 for multiple layers and the outer frame steel structure 2 exceeds the horizontal structure of the inner tube (not shown in the figure) by many During the first layer, the two ends of the first high-altitude corridor 3 are respectively arranged on the relative first connecting beam 11 and the second connecting beam 12 of the vertical wall body 1 of the core tube;

[0043] Preferably, when the vertical wall 1 of the core tube exceeds the outer f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com