Shield pipe rack system and construction method thereof

A construction method and technology for shield tunneling, which are applied in the fields of earthwork drilling, mining equipment, tunnels, etc., can solve the complex construction process of the comprehensive node of the pipe gallery, increase the overall construction period of the shield tunnel, and the long construction period of the comprehensive node of the pipe gallery. and other problems, to achieve the effect of flexible location of the integrated node unit of the pipe gallery, reducing the overall construction period and reducing the shield construction period.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

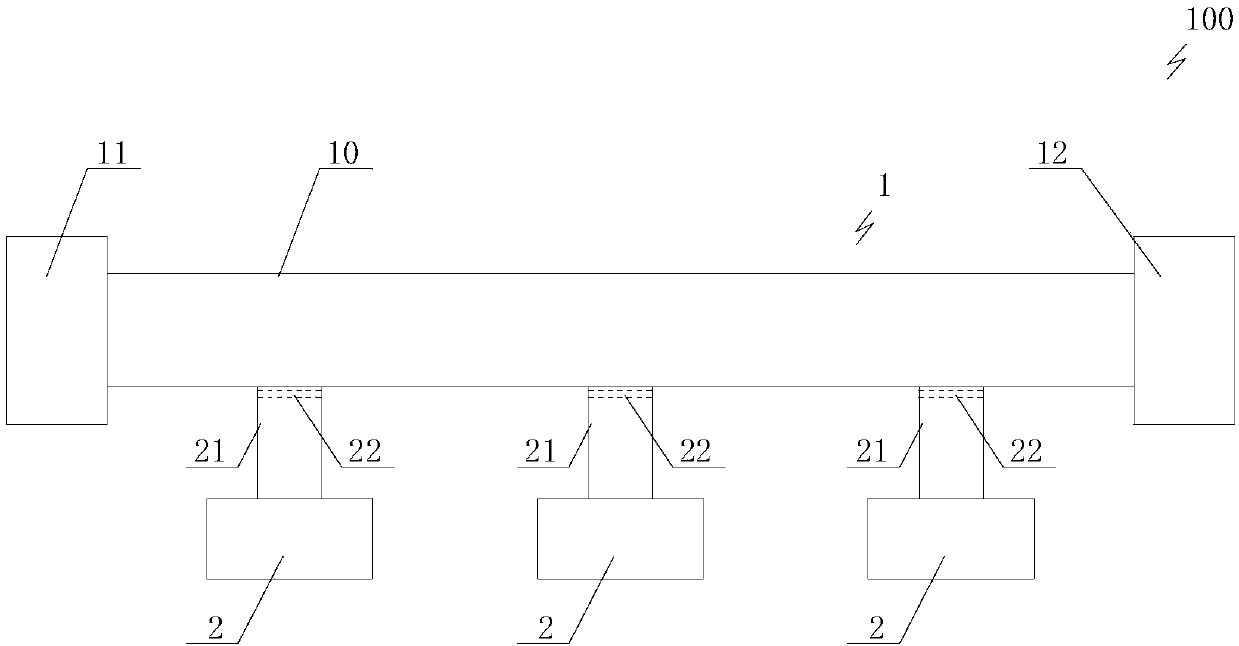

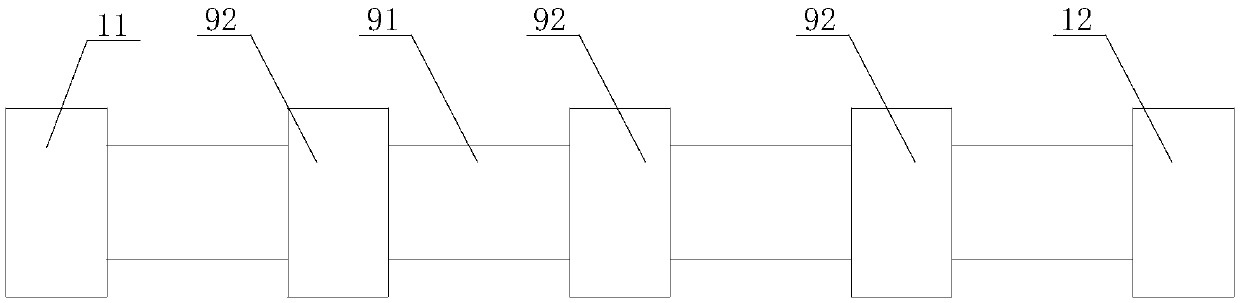

[0035] Such as figure 1 As shown, the present invention provides a shield tunnel system 100. The shield tunnel system 100 includes a plurality of shield tunnel standard sections 10 spliced longitudinally or a shield tunnel standard section 10 composed of a tunnel main line 1 , the two ends of the standard section 10 of the shield tunnel tunnel are respectively provided with a shield tunnel initiation shaft 11 and a shield tunnel termination shaft 12, and a plurality of tunnel integrated node units 2 are arranged at intervals on the outer side of the main line 1 of the tunnel tunnel (the integrated nodes of each tunnel tunnel The distance between the units meets the requirements of the pipe gallery specification), the comprehen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com