Cylindrical combined heat exchanger

A technology of heat exchangers and heat exchange cores, applied in the direction of heat exchanger types, indirect heat exchangers, fixed tubular conduit components, etc., can solve problems such as scrapping, inconvenient disassembly and maintenance, and strong integrity, and achieve heat exchange Good effect, easy to disassemble and maintain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

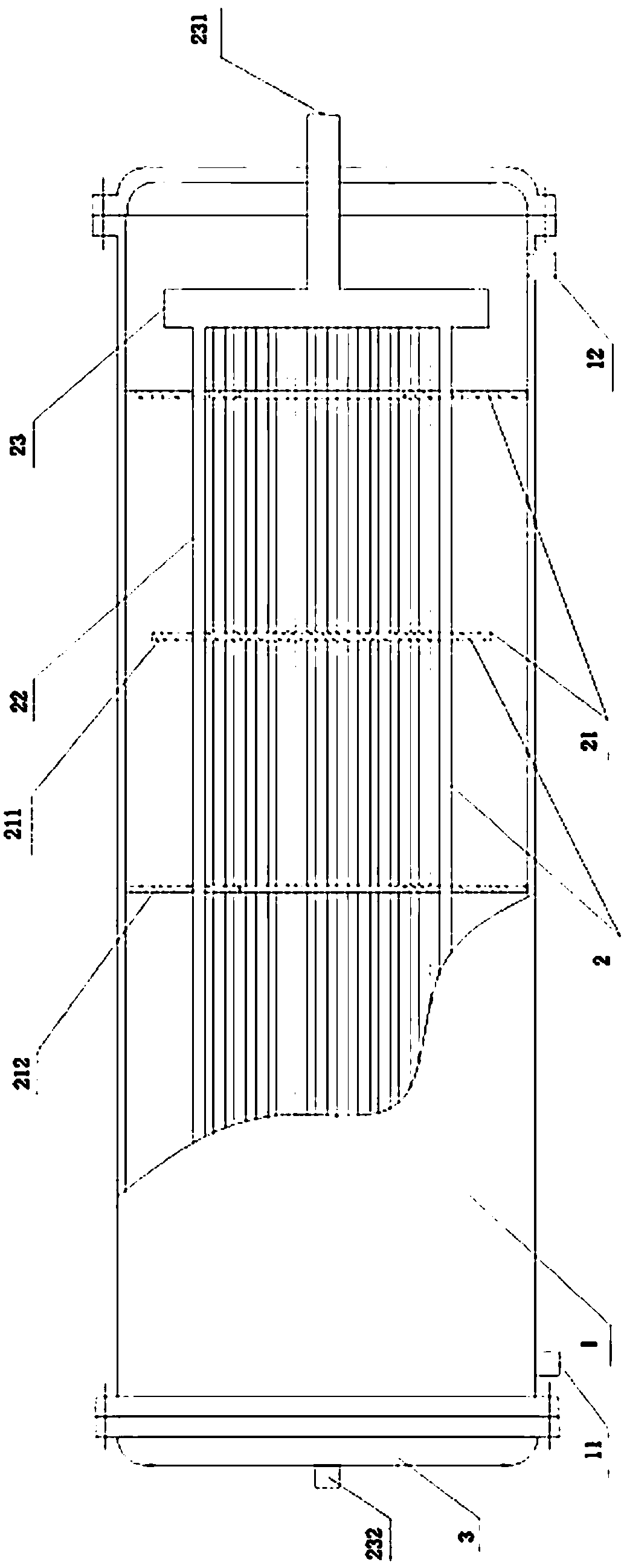

[0016] The cylindrical combined heat exchanger is composed of a cylindrical body (1), a heat exchange core (2), and an end plug (3). Sealed assembly end plug (3); reserve a water inlet (11) on the side of one end of the cylinder (1) or on the end plug (3) at the same end, and reserve a water outlet on the side of the other end or the end plug (3) at this end ( 12); one end of the heat exchange core (2) is reserved for the medium inlet (231), and the other end is reserved for the medium outlet (232), the medium inlet (231) and the medium outlet (232) pass through the end plug (3) and conduct with the outside ; Both the medium inlet (231) and the medium outlet (232) are sealed with the end plug (3).

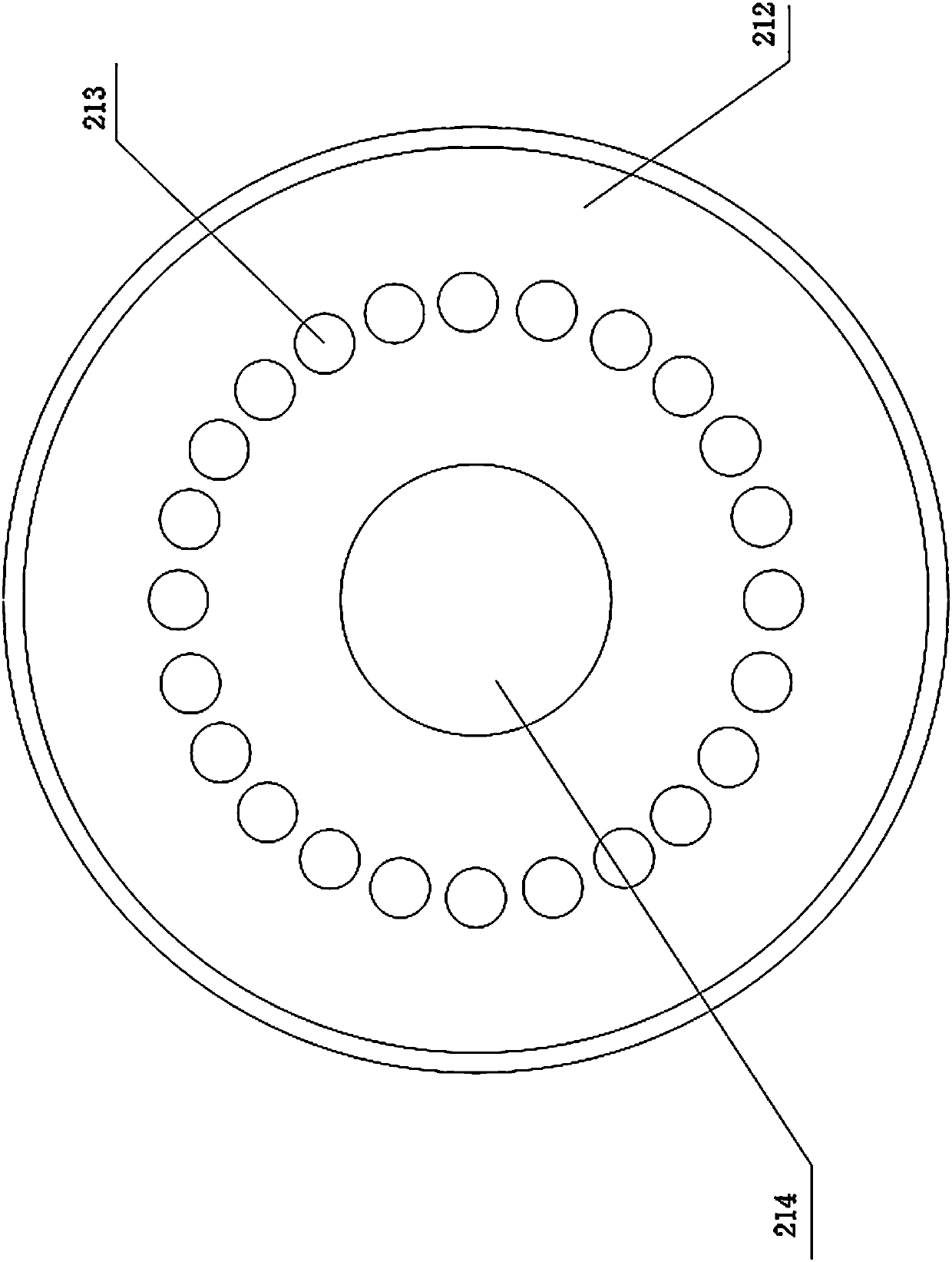

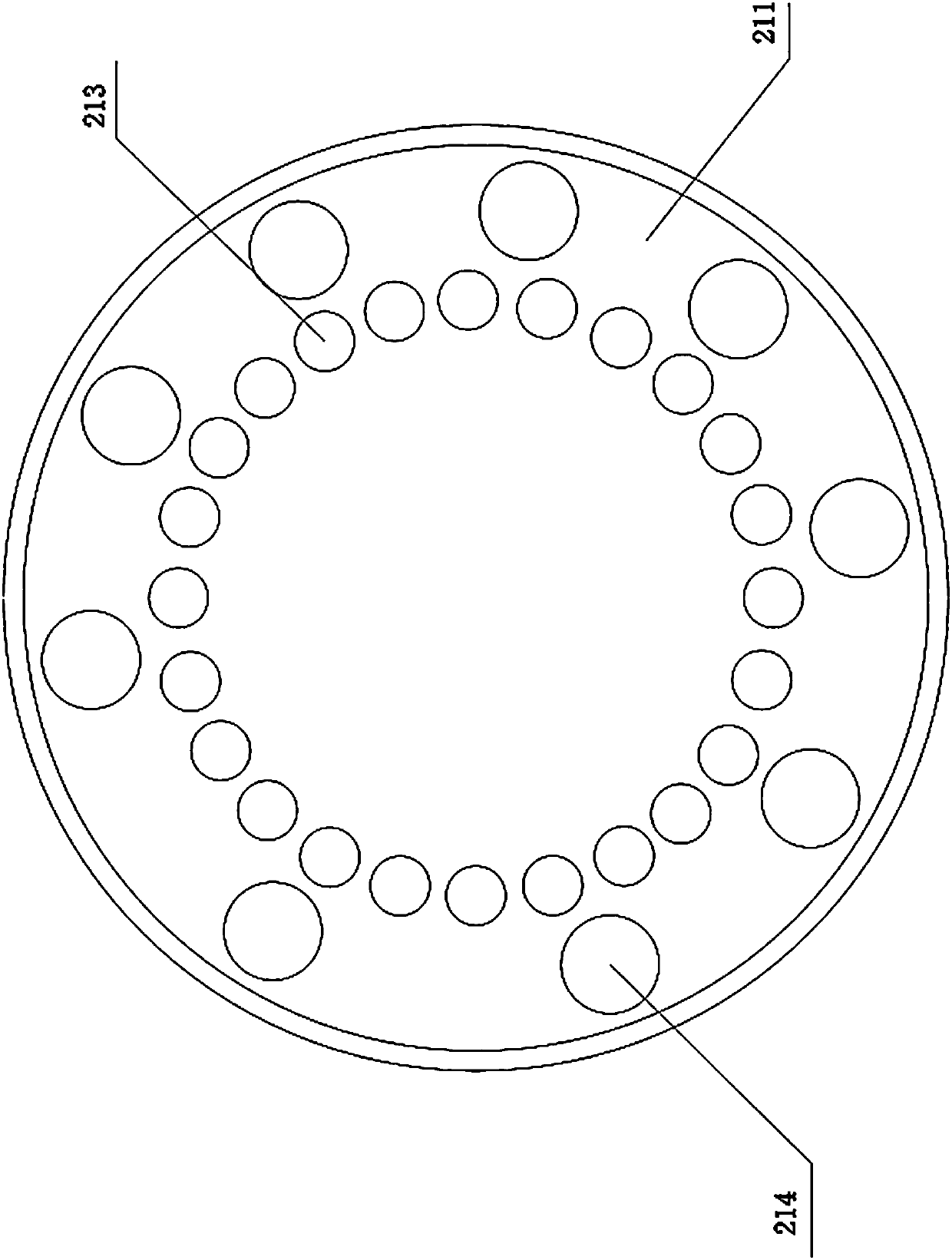

[0017] As mentioned above, the heat exchange core (2) includes a limiting deflector (21), a heat exchange tube (22), and a collection box (23); the limiting holes (213) are regularly distributed on the limiting deflector (21) and diversion hole (214), according to the distribution...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com