Automatic draining device in salt spray test box

A technology of salt spray test and automatic drainage, which can be used in measuring devices, instruments, scientific instruments, etc., and can solve the problems of affecting the test results of test pieces, long cycle, and prolonged spray time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

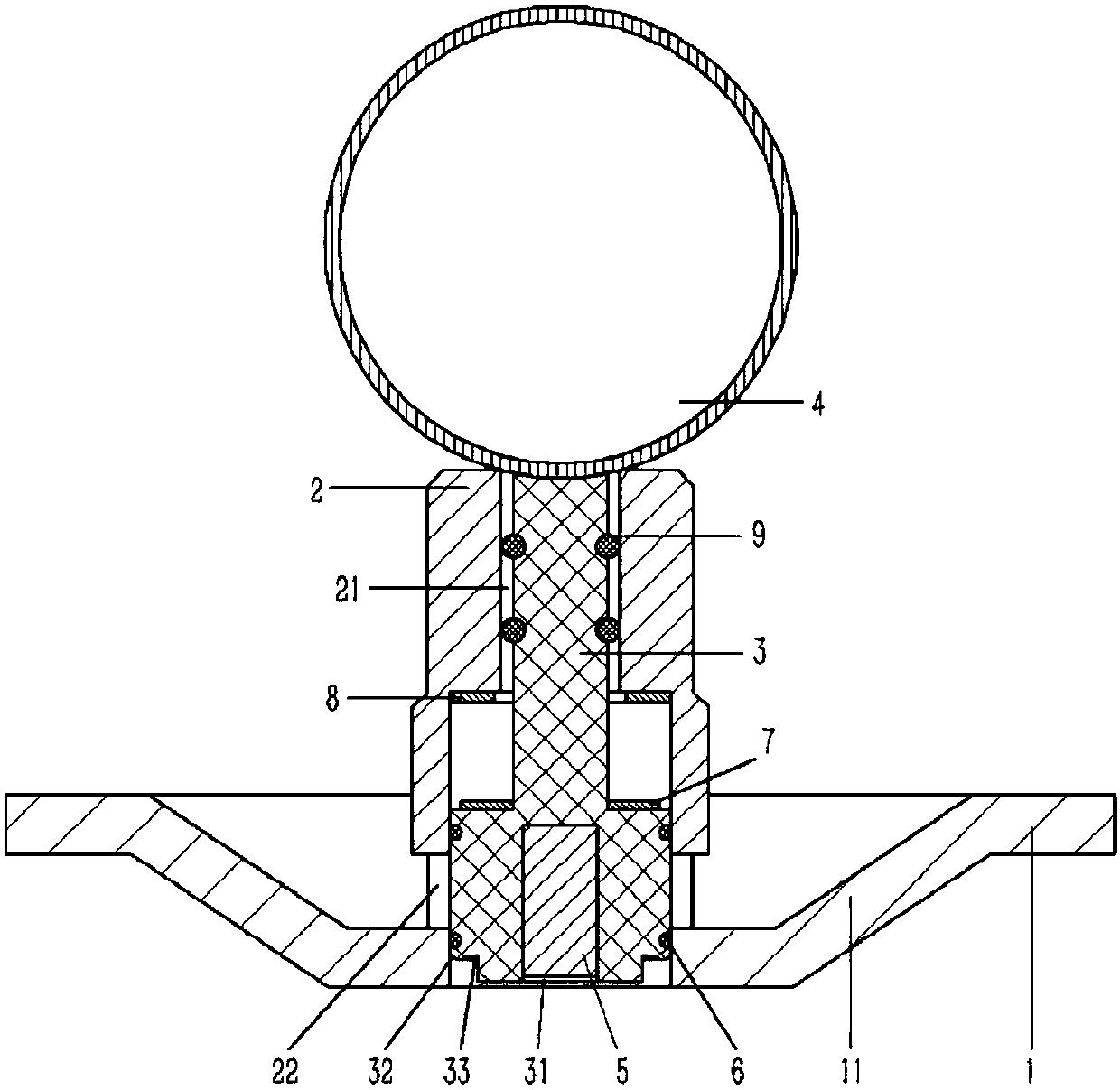

[0014] Example: see figure 1 As shown, an automatic drainage device in a salt spray test chamber includes a bottom plate 1 in the salt spray test chamber. A conical sinking platform 11 is bent and formed on the bottom plate 1, and a water leakage hole is formed on the bottom surface of the sinking platform 11. The bottom surface of sinking platform 11 is fixed with the drainage seat 2 that communicates with the leak hole, the bottom surface of the drainage seat 2 is formed with a step hole 21 that runs through the upper end surface of the drainage seat 2, and the outer wall opposite to the lower end of the drainage seat 2 is formed with a step. The hole 21 is connected to the drain hole 22, and the step hole 21 of the drain seat 2 is inserted with a T-shaped sealing plug 3. The sealing plug 3 is composed of a head and a handle, and the head of the sealing plug 3 is inserted into the In the leakage hole of the base plate 1, the handle of the sealing plug 3 passes through the dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com