A current drift correction method, system and device for a battery management system

A battery management system and drift correction technology, applied in measurement devices, measurement of current/voltage, measurement of electricity, etc., can solve problems such as poor robustness and poor compatibility, and achieve low cost, good robustness, and good compatibility. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

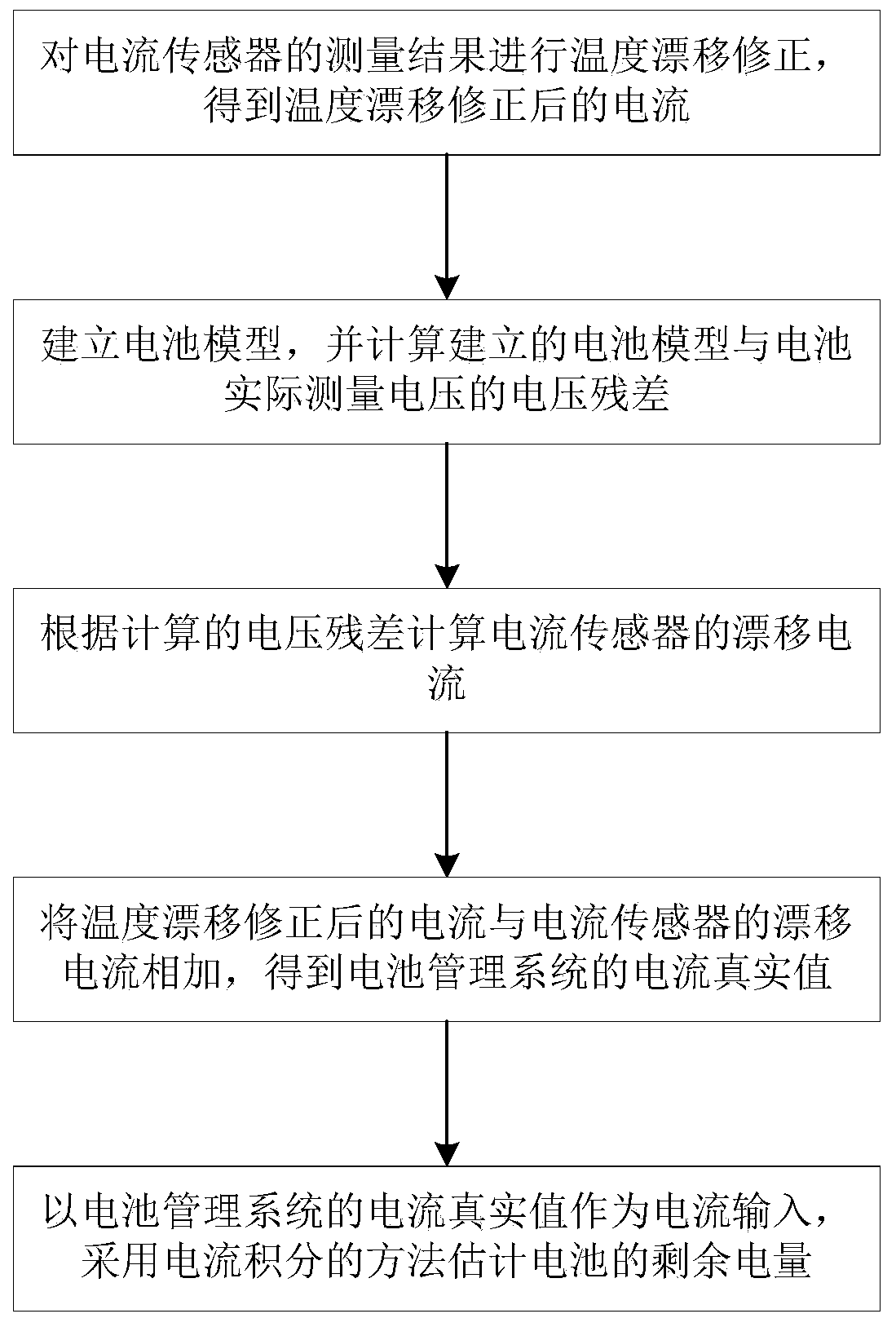

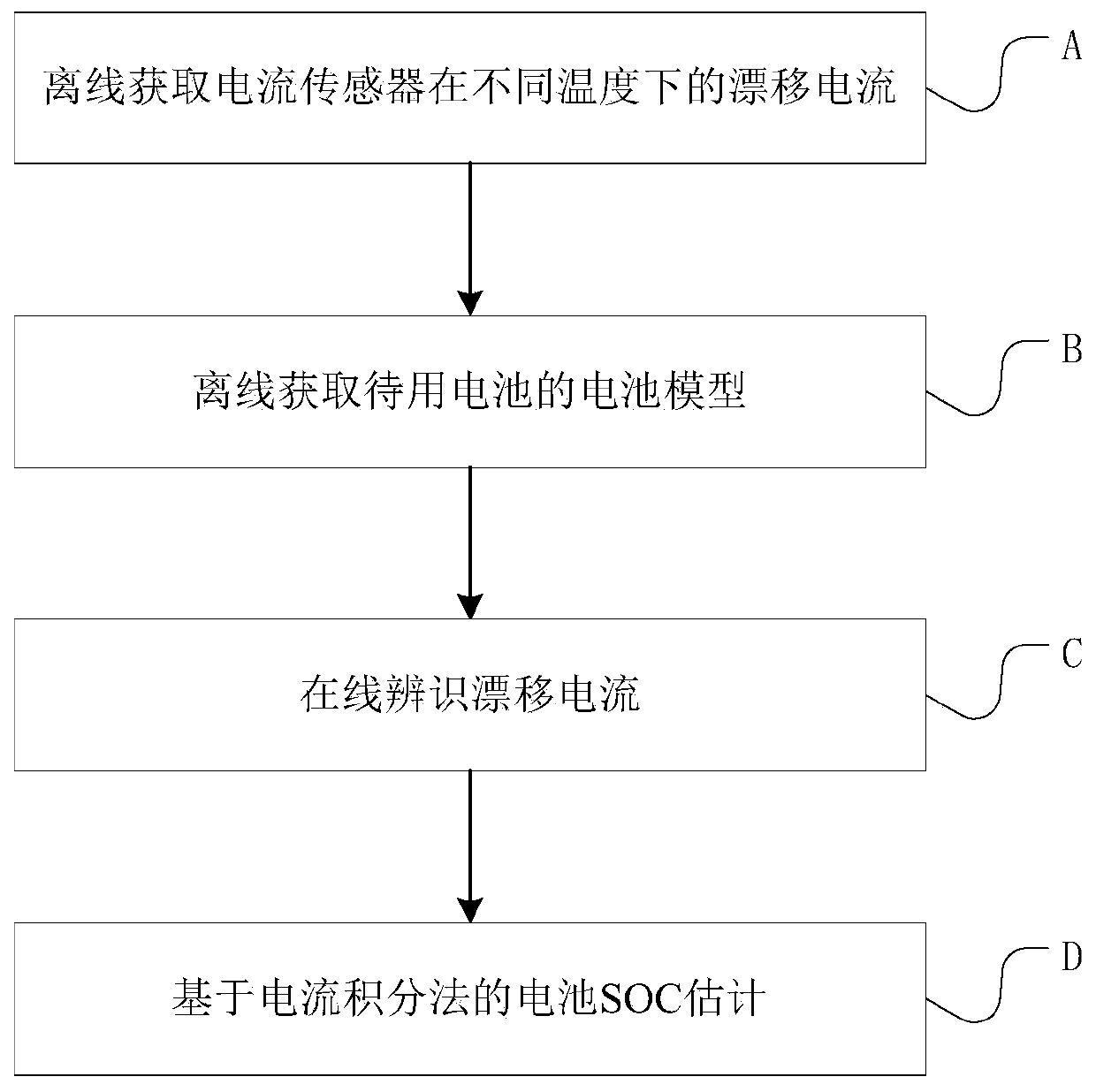

[0091] refer to figure 2 , this embodiment uses the current drift correction method of the present invention to estimate the remaining power of the lithium iron phosphate battery, which specifically includes the following steps:

[0092] A. Obtain the drift current of the current sensor at different temperatures offline;

[0093] B. Obtain the battery model of the battery to be used offline;

[0094] C. Online identification of drift current;

[0095] D. Battery SOC estimation based on current integration method.

[0096] The step A can be specifically subdivided into the following steps:

[0097] A1. Obtain the measurement results MI when the current sensor measures different currents at different temperatures T;

[0098] A2. Perform numerical fitting on the result MI of step A1 and the real value RI to obtain a fitting relationship f() between the two, and the fitting relationship f() can be expressed as: RI=f(MI,T);

[0099] A3. Calculate the measured current I of the...

Embodiment 2

[0130] This embodiment uses a method similar to that of embodiment 1 to estimate the remaining power of the lithium iron phosphate battery. The main differences between it and embodiment 1 are the following three points:

[0131] 1) In the present embodiment, the expression of fitting relation f () in step A2 is:

[0132] RI=(1.123+0.1662*MI-0.004063*MI*MI-0.1168 / MI)*(1.928+0.1929*△T-0.002464*△T*△T-0.147 / △T)

[0133] Wherein, ΔT represents the difference between the current temperature sensor temperature and 0 degrees Celsius, namely: ΔT=(T-0). In actual use, T is generally greater than 0 degrees Celsius.

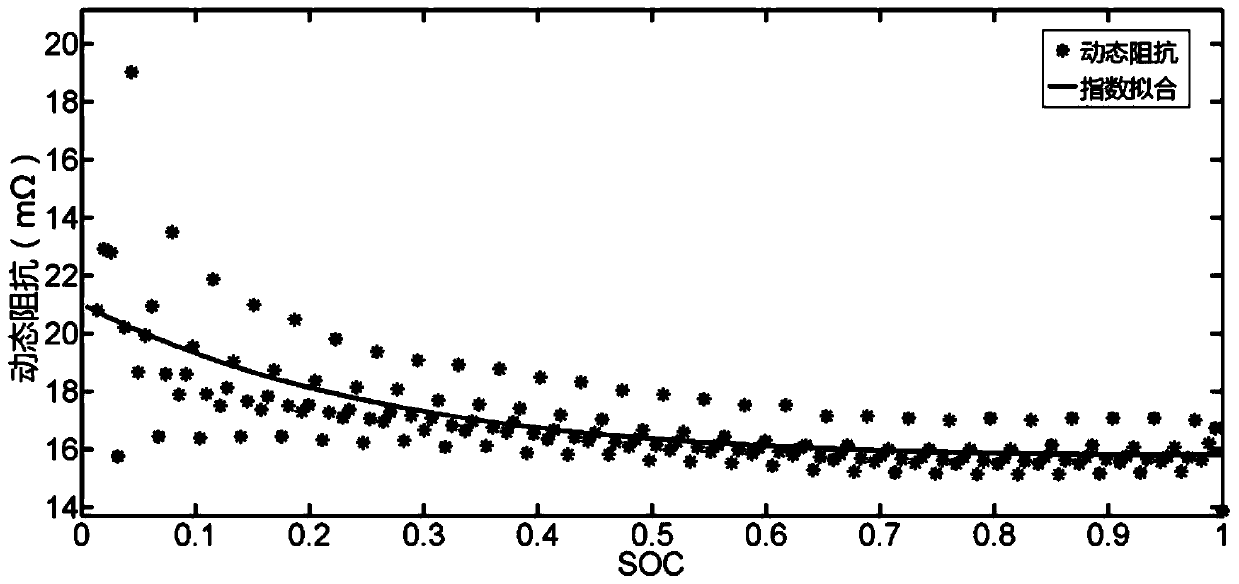

[0134] 2) The expression of the battery model fitted in step B1 in this embodiment is:

[0135] u oc = β 0 +β 1 SOC+β 2 SOC 2 +β 3 SOC 3 +β 4 SOC 4 +β 5 SOC 5

[0136] Among them, U oc is the open circuit voltage of the battery, β 0 , β 1 , β 2 , β 3 , β 4 and beta 5 Both are battery model parameters, which can be preset or given.

[0137] 3) In this e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com