Graphene-based heating apparatus

A heating device and graphene technology, applied in the graphene field, can solve problems such as graphene electric heating film damage, and achieve the effects of fast heating, convenient replacement, and convenient power on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

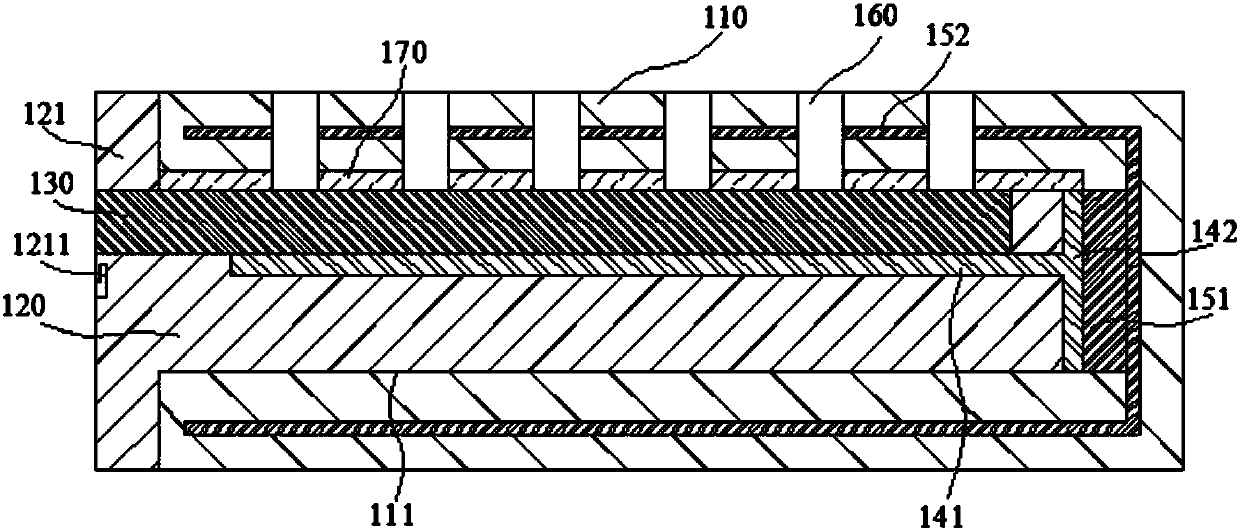

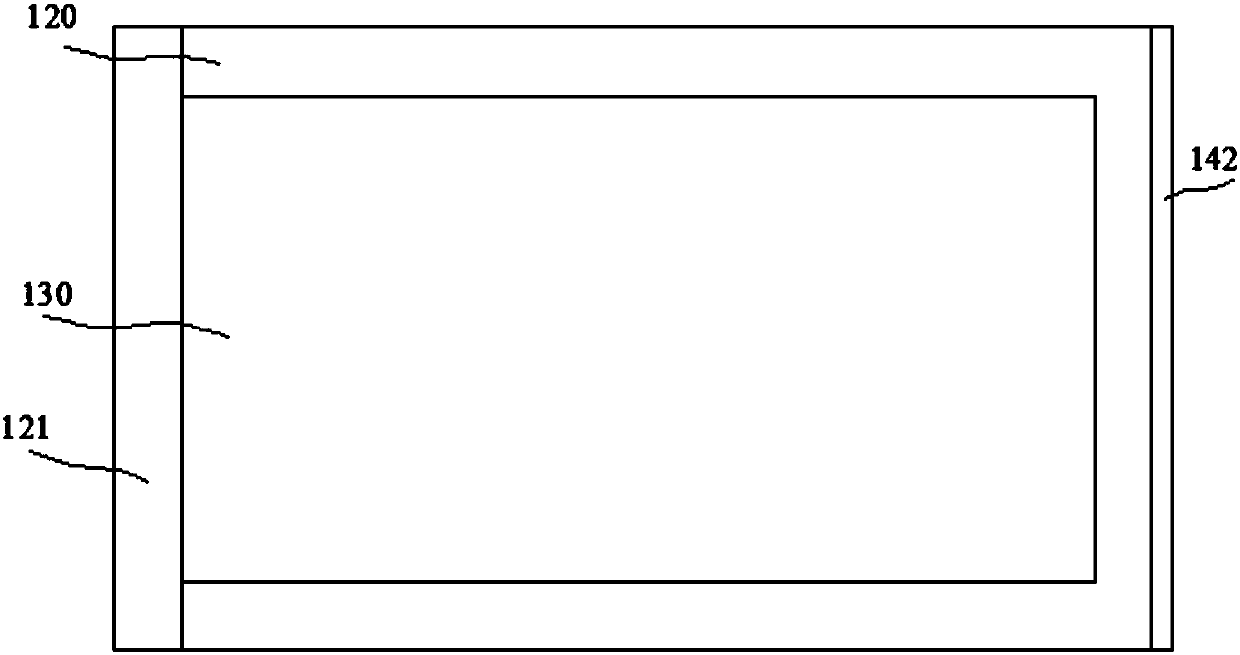

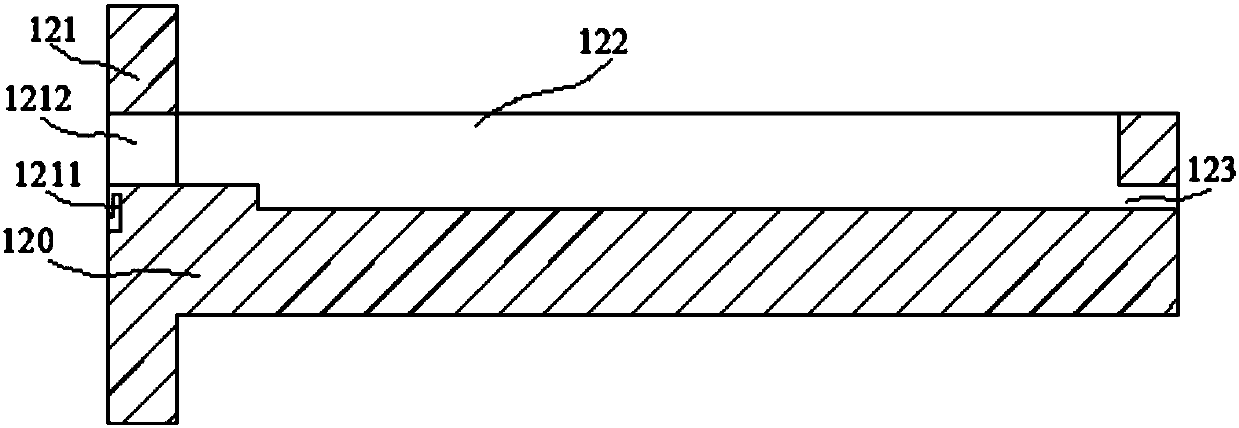

[0073] Such as figure 1 As shown, the present embodiment provides a graphene-based heating device, including a protective layer 110, the protective layer 110 is provided with an installation cavity 111 with an opening to the left, and a support plate 120 is inserted in the installation cavity 111, and the support plate 120 is left A baffle 121 is provided on the side, and the baffle 121 is located on the left side of the installation cavity 111 and the baffle 121 is attached to the left side of the protective layer 110 .

[0074] The support plate 120 is inserted into the installation cavity 111 of the protective layer 110, so that the protective layer 111 can effectively protect the support plate 120. The baffle 121 is located on the left side of the support plate 120 and connected in one piece. The baffle 121 plays a role The position limiting function can also facilitate the insertion or withdrawal of the support plate 120 into or out of the installation cavity 111 .

[00...

Embodiment 2

[0091] Such as Figure 5 , Image 6 with Figure 7 As shown, the present embodiment provides a fixed structure of a graphene electrothermal film, including a protective layer 110, the protective layer 110 is provided with an installation cavity 111 with an opening to the left, and a support plate 120 is inserted in the installation cavity 111, and the support plate 120 A baffle 121 is provided on the left side, and the baffle 121 is located on the left side of the installation cavity 111 and the baffle 121 is attached to the left side of the protective layer 110 .

[0092] The support plate 120 is inserted into the installation cavity 111 of the protective layer 110, so that the protective layer 111 can effectively protect the support plate 120. The baffle 121 is located on the left side of the support plate 120 and connected in one piece. The baffle 121 plays a role The position limiting function can also facilitate the insertion or withdrawal of the support plate 120 into ...

Embodiment 3

[0109] Such as Figure 8 As shown, this embodiment provides a heating device using graphene to generate heat, including a protective layer 110, an installation cavity 111 with an opening to the left is provided in the protection layer 110, a support plate 120 is inserted in the installation cavity 111, and the support plate 120 A baffle 121 is provided on the left side, and the baffle 121 is located on the left side of the installation cavity 111 and the baffle 121 is attached to the left side of the protective layer 110 .

[0110] The support plate 120 is inserted into the installation cavity 111 of the protective layer 110, so that the protective layer 111 can effectively protect the support plate 120. The baffle 121 is located on the left side of the support plate 120 and connected in one piece. The baffle 121 plays a role The position limiting function can also facilitate the insertion or withdrawal of the support plate 120 into or out of the installation cavity 111 .

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com