Coffee maker

A coffee machine and coffee technology, applied in beverage preparation devices, household appliances, applications, etc., can solve the problems of low efficiency of iced coffee, achieve the effects of improving production efficiency, simple operation, and saving production time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

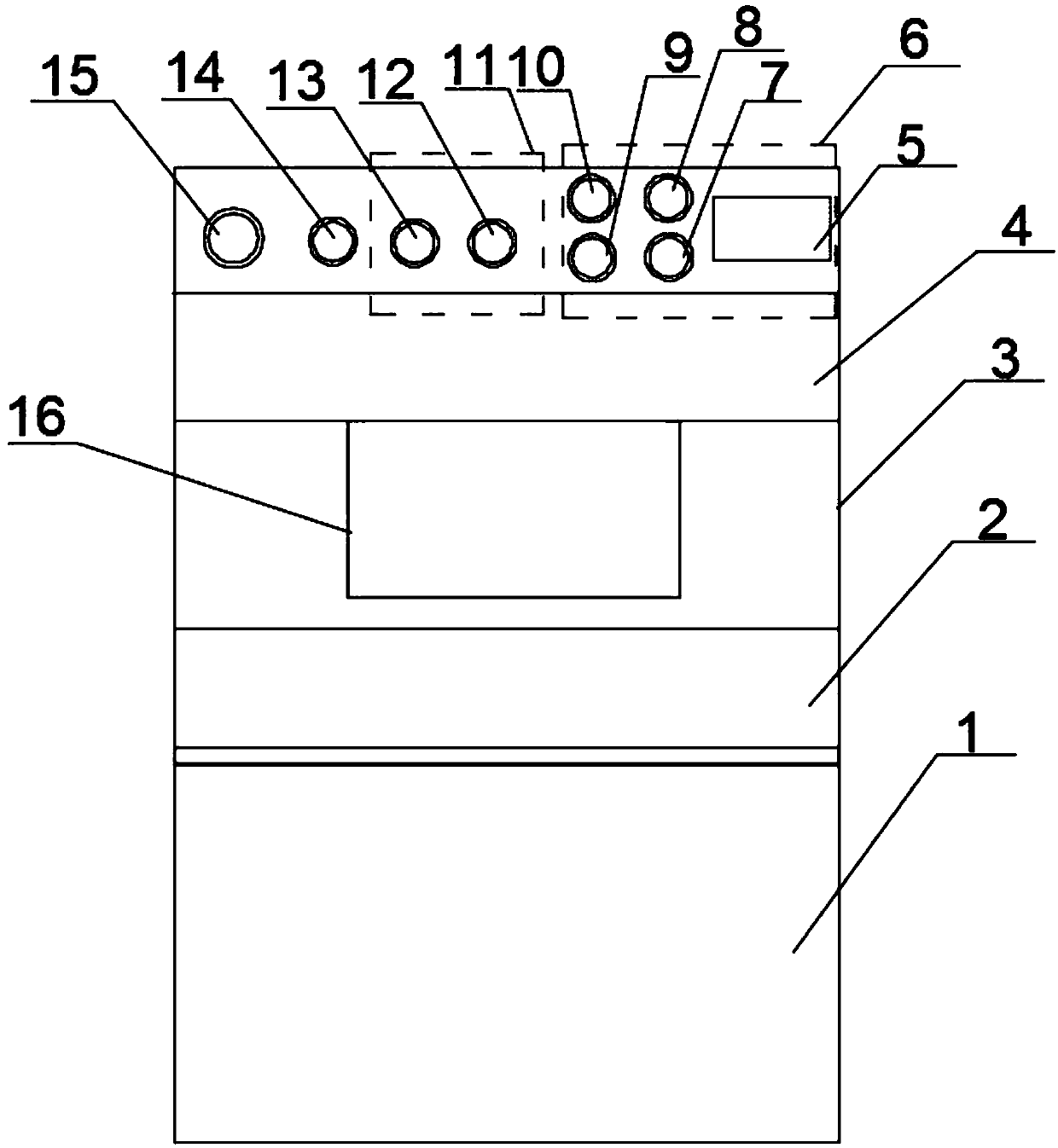

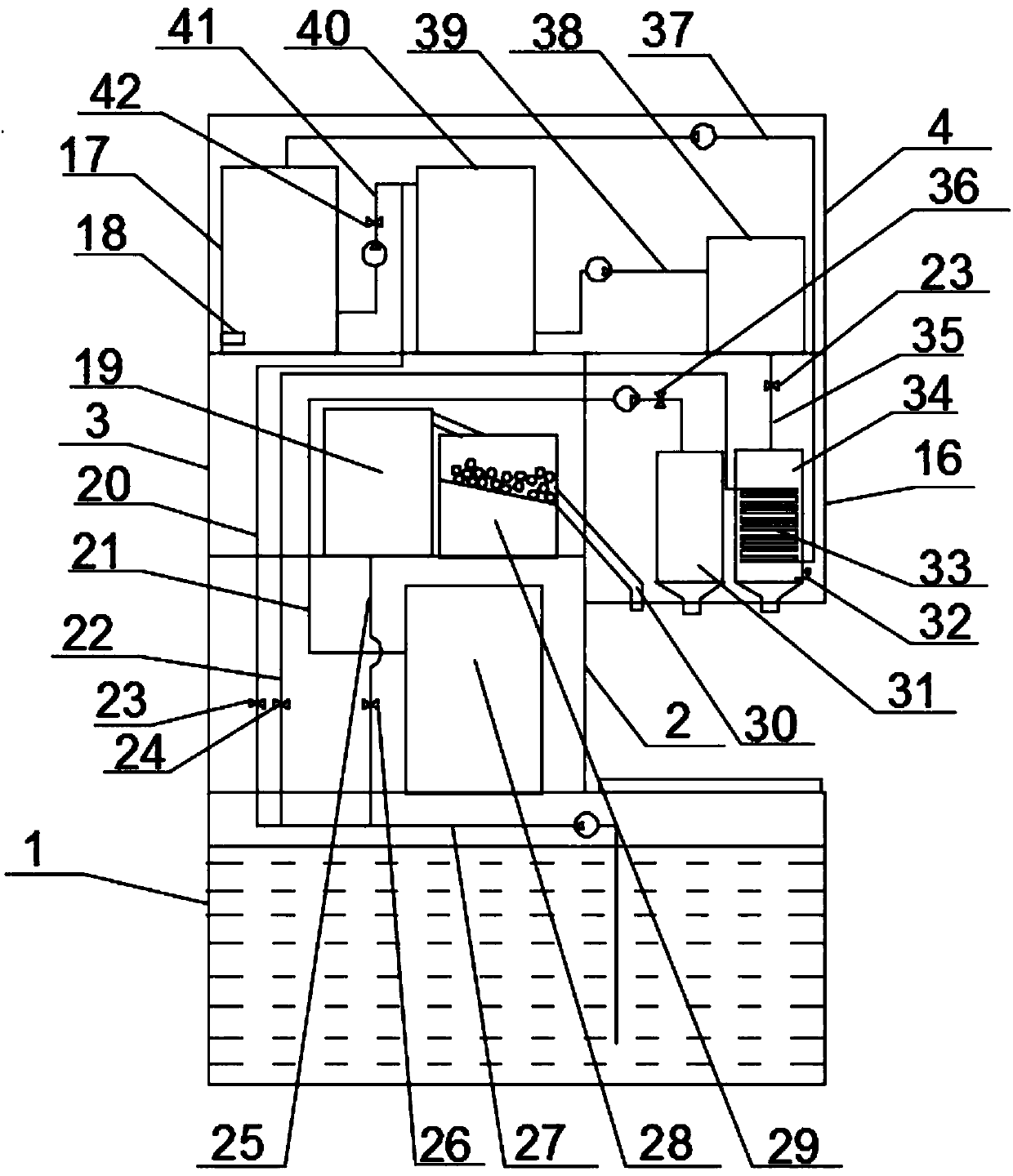

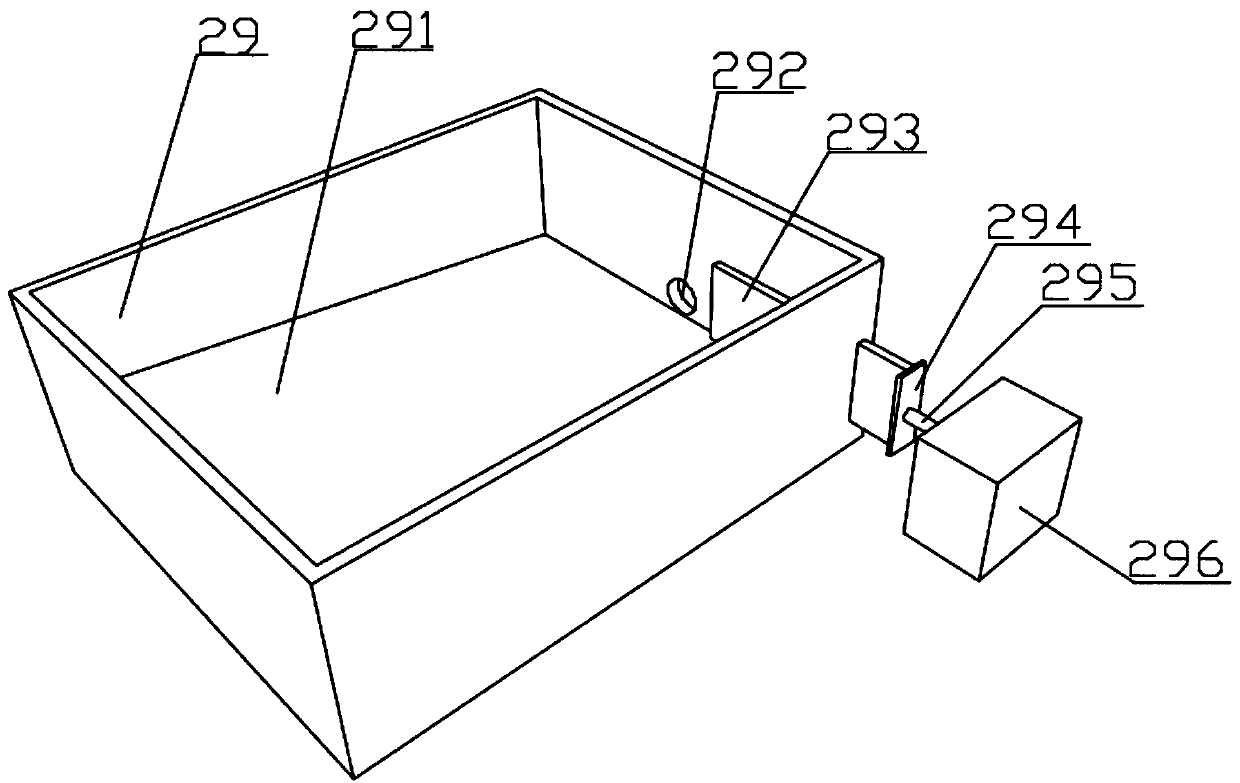

[0030]A coffee machine, comprising a hot coffee making chamber 4, an ice making chamber 3 and a water supply chamber 1 arranged sequentially from top to bottom, one side of the ice making chamber 3 is provided with an iced coffee making chamber 16, the iced coffee making chamber The chamber 16 is located below the hot coffee making chamber 4 and forms a space for accommodating coffee cups with the water supply chamber 1; the hot coffee making chamber 4 is provided with a heating container 40 and a brewing device 38, and the entrance of the heating container 40 The first water inlet pipe 20 communicates with the water supply chamber 1, and the outlet of the heating container 40 is connected with the brewing device 38 through the hot water outlet pipe 39; The ice storage box 29, the ice machine 19 communicates with the water supply chamber 1 through the second water inlet pipe 25, the ice storage box 29 is provided with an ice cube outlet 292, and the ice cube outlet 292 is conne...

Embodiment 2

[0033] Based on Embodiment 1, a refrigeration container 34 is provided with a refrigeration pipeline 33, one end of the refrigeration pipeline 33 communicates with the water supply chamber 1 through the third water inlet pipe 22, and the other end is connected with a drain pipe 37, and the third water inlet pipe 22 is provided with The third solenoid valve 24, the third solenoid valve 24 is electrically connected with the iced coffee making controller 6. When it is necessary to make iced coffee, the iced coffee making controller 6 controls the third electromagnetic valve 24 to open, and the water supply chamber 1 supplies water to the refrigeration pipeline 33, and when the cold water flows through the refrigeration pipeline 33, it exchanges heat with the hot coffee to achieve the cooling effect. The cold water is discharged from the drain pipe 37 after being heated.

[0034] A temperature sensor 32 is arranged in the cooling container 34, and the temperature sensor 32 is elec...

Embodiment 3

[0036] Based on Embodiment 2, the end of the drain pipe 37 far away from the cooling pipeline 33 is connected to the heat preservation tank 17, and the heat preservation tank 17 is connected to the first water inlet pipe 20 through the water outlet pipe 41, and the water outlet pipe 41 is provided with a one-way valve 42 . The heat-exchanged and heated cooling water is preserved by setting the thermal insulation tank 17. When making coffee next time, the hot coffee making controller 11 can first control the one-way valve 42 to open, so that the hot water in the thermal insulation tank 17 can pass through the outlet pipe. 41. The first water inlet pipe 20 enters the heating container 40 to realize heat recovery and utilization. The one-way valve 42 can ensure that the water from the water supply chamber 1 in the first water inlet pipe 20 will not flow back to the insulation tank 17 .

[0037] A water level sensor 18 is provided in the thermal insulation tank 17, and the water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com