A kind of hydrophobic association type amphoteric polyacrylamide and its preparation method and application

A polyacrylamide and hydrophobic association technology, which is applied in the direction of flocculation/sedimentation water/sewage treatment, etc., can solve the problem that the hydrophobic association cannot meet the needs of the market, etc., so that the product preparation process can be easily controlled and the hydrophobic association ability can be enhanced. , The effect of improving the adsorption and bridging capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

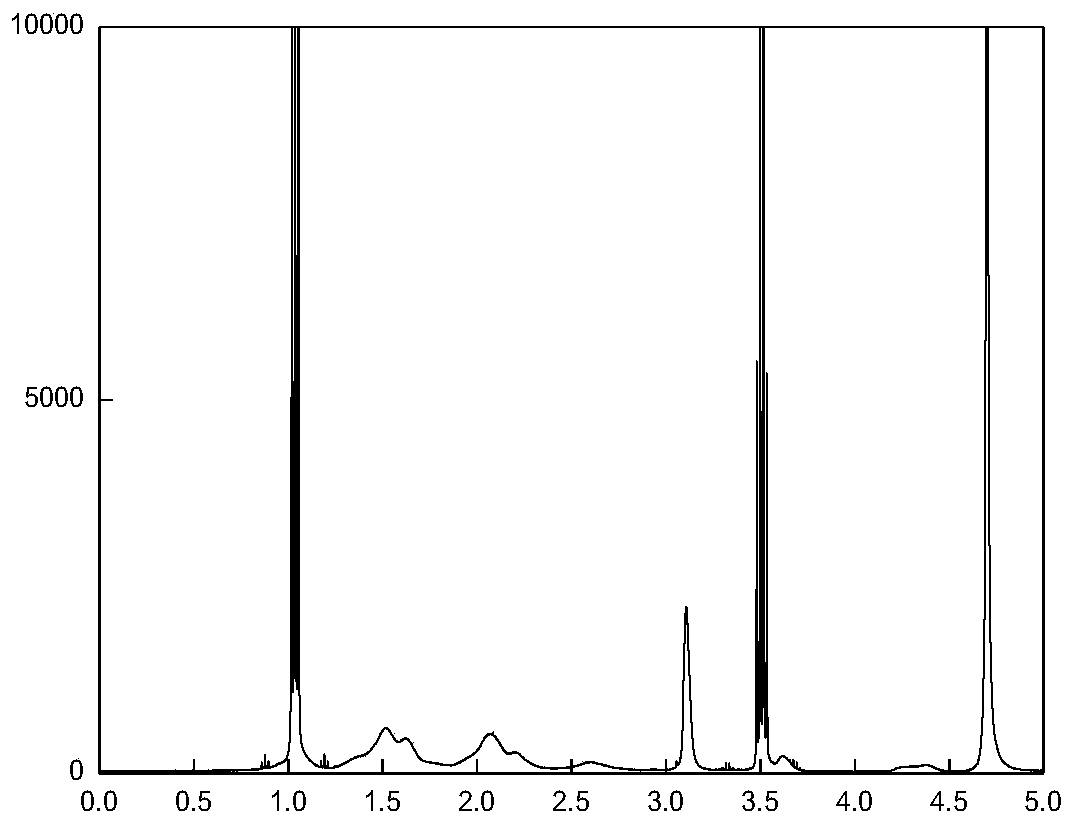

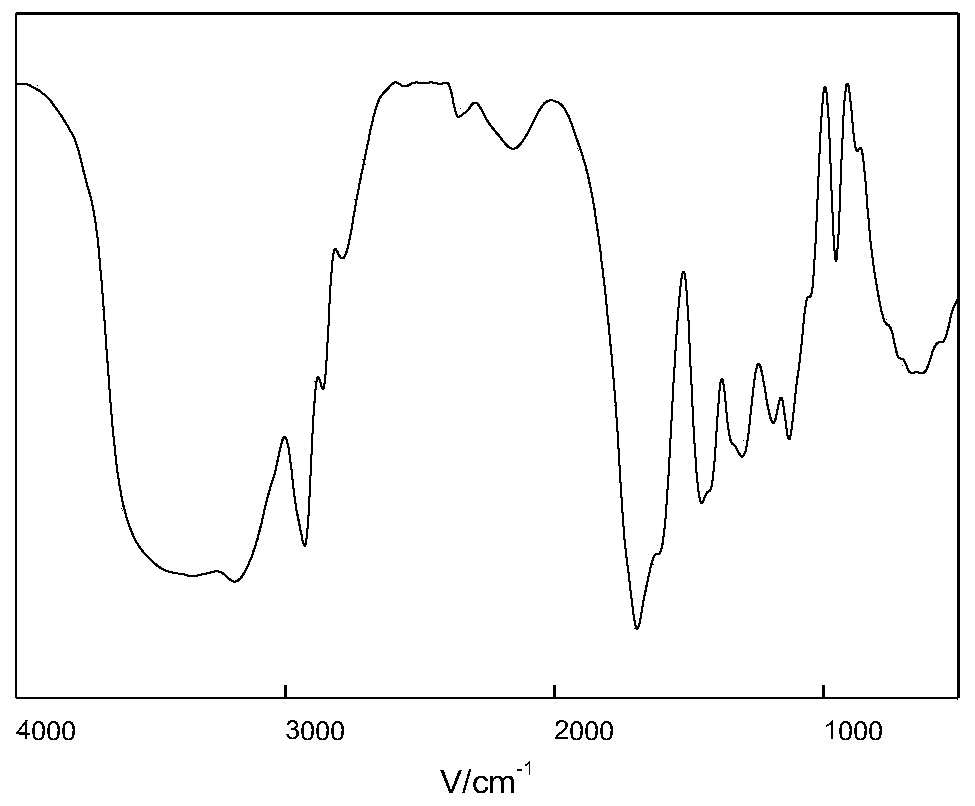

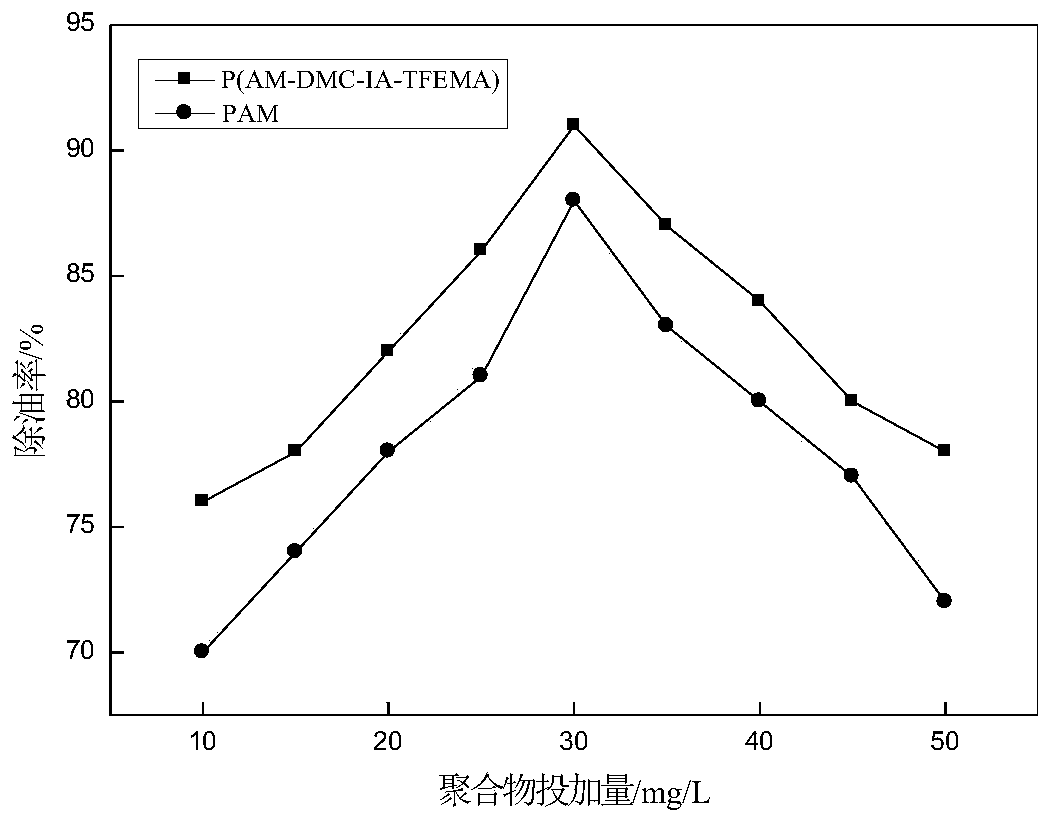

Image

Examples

Embodiment 1

[0029] (1) In a three-necked flask equipped with a stirrer and a spherical condenser, add trifluoroethyl methacrylate, methacryloyloxyethyltrimethyl Ammonium Chloride, Itaconic Acid, Acrylamide, Sodium Lauryl Sulfate, and Deionized Water.

[0030] (2) Fill the reaction device with high-purity nitrogen, remove the air in the reaction device completely after 0.5 h, and then heat and stir.

[0031] (3) At 55°C, use a constant-pressure dropping funnel to add dropwise a mixed solution of ammonium persulfate and sodium bisulfite (mass ratio: 3:2) with a total mass of monomers of 1.5%. Heat to reflux for 4 hours until the reaction viscosity does not change any more, then stop the reaction.

[0032] (4) Take out the product, wash the solution with ethanol and acetone with a volume ratio of 1:1, until the solution is clear, and then extract the product with ethanol-acetone solution in Soxhlet extraction for 12 hours to remove unreacted raw material monomers As well as the surfactant,...

Embodiment 2

[0036] (1) In a three-necked flask equipped with a stirrer and a spherical condenser, add hexafluorobutyl methacrylate and dimethyl diallyl ammonium chloride at a mass ratio of 1:4:4:9:27 , itaconic acid, acrylamide, sodium lauryl sulfate, and deionized water.

[0037] (2) Fill the reaction device with high-purity nitrogen, remove the air in the reaction device completely after 1 hour, and then heat and stir.

[0038] (3) At 60°C, use a constant pressure dropping funnel to add dropwise a mixed solution of potassium persulfate and sodium bisulfite (mass ratio: 3:2) with 1.0% of the total mass of the monomers. Heat to reflux for 3 hours until the reaction viscosity does not change any more, then stop the reaction.

[0039](4) Take out the product, wash the solution with ethanol and acetone with a volume ratio of 1:1, until the solution is clear, and then extract the product with ethanol-acetone solution in Soxhlet extraction for 12 hours to remove unreacted raw material monomer...

Embodiment 3

[0041] (1) Add trifluoroethyl acrylate, dimethylaminoethyl methacrylate, and itaconic acid into a three-necked flask equipped with a stirrer and a spherical condenser at a mass ratio of 1:5:5:10:26. , acrylamide, sodium lauryl sulfate, and deionized water.

[0042] (2) Fill the reaction device with high-purity nitrogen, remove the air in the reaction device completely after 0.7h, and then heat and stir.

[0043] (3) At 65° C., a constant-pressure dropping funnel was used to drop a potassium persulfate solution of 2.0% of the total mass of the monomers. Heat to reflux for 3.5 hours until the reaction viscosity no longer changes, and stop the reaction.

[0044] (4) Take out the product, wash the solution with ethanol and acetone with a volume ratio of 1:1, until the solution is clear, and then extract the product with ethanol-acetone solution in Soxhlet extraction for 12 hours to remove unreacted raw material monomers As well as the surfactant, the washed product is put into a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com