A laser portable mwd angle difference ruler and its application method

A portable, angular difference technology, which is applied in earthwork drilling, optical devices, measurement, etc., can solve the problems of low accuracy of angular difference measurement, inefficient construction, large trajectory deviation, etc., and achieve the effect of improving the accuracy of angular difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

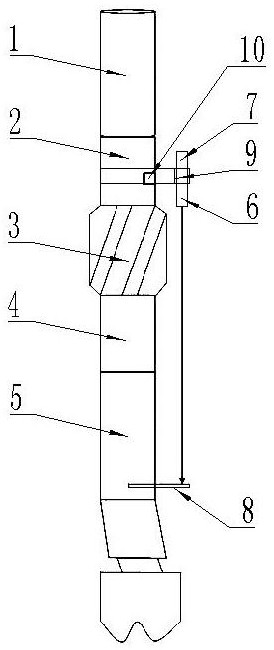

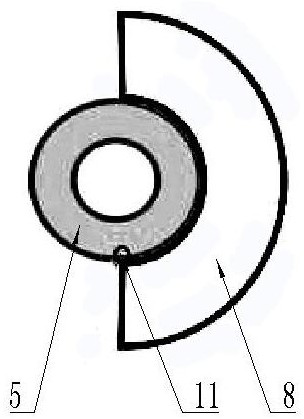

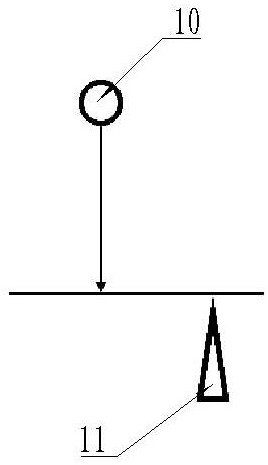

[0027] Such as figure 1 with figure 2 As shown, a laser portable MWD angular difference ruler includes non-magnetic drill collars 1, MWD directional joints 2, centralizers 3, short drill collars 4 and screw rods 5 connected in sequence, and on the side wall of the MWD directional joint 2 A laser pointer 6 is installed, and the light source of the laser pointer 6 is set downwards. A screw high-side marking groove 11 is provided at the screw bending point on the side wall of the lower half of the screw rod 5, and the screw high-side marking groove 11 is abutted with an angular difference by a ruler 8 The 0° scale on the panel of the angular difference is close to the high-side mark groove, and the panel of the angular difference is placed horizontally, and the beam emitted by the laser pointer 6 forms a light spot on the panel of the angular difference.

[0028] When in use, the laser pointer 6 is installed on the side wall of the MWD directional joint 2, so that the light bea...

Embodiment 2

[0031] Such as figure 1 As shown, a laser pointer fixing card 7 is clamped on the side wall of the MWD directional joint 2, and a ring 9 is opened on the laser pointer fixing card 7, and the laser pointer 6 is clamped in the ring 9.

[0032] A positioning bolt 10 that can adjust the position of the laser pointer fixing card 7 is provided at the middle position in the vertical direction of the MWD directional joint 2 , and the positioning bolt 10 is flush with the side wall of the MWD directional joint 2 .

[0033] The laser pointer 6 has the same diameter as the positioning bolt 10 .

[0034] In the process of installing the laser pointer 6 on the side wall of the MWD orientation joint 2, the laser pointer 6 is clamped in the ring 9 of the laser pointer fixing card 7, and the laser pointer fixing card 7 is stuck on the MWD orientation through the buckle. Connector 2. The position of the laser pointer fixing card 7 can be better fixed by the positioning bolt 10. The positioni...

Embodiment 3

[0036] Such as figure 2 As shown, the angular difference ruler 8 includes a front side and a back side, and both the front side and the back side are marked with 0°~180° marks.

[0037] When set bolt 10 is positioned at screw rod high side marking groove 11 left side, angle difference is leaned on ruler 8 panel face up, and when set bolt 10 is positioned at screw rod high side mark groove 11 right side, angle difference leans against ruler 8 panel reverse side upwards.

[0038] Regardless of whether the positioning bolt 10 on the MWD directional joint 2 is located on the left or right side of the marking groove 11 on the high side of the screw rod, the angular difference measurement can be performed conveniently and quickly by using the angular difference ruler 8, which is convenient for technicians to operate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com