Automobile brake device and method

A braking device and automobile technology, applied in the direction of braking transmission, brakes, brake types, etc., can solve the problems of slow braking response, failure of the braking system to achieve energy recovery, and the failure of the braking system to achieve active braking. Achieve the effects of coercive action, high practical value, and accelerated braking speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

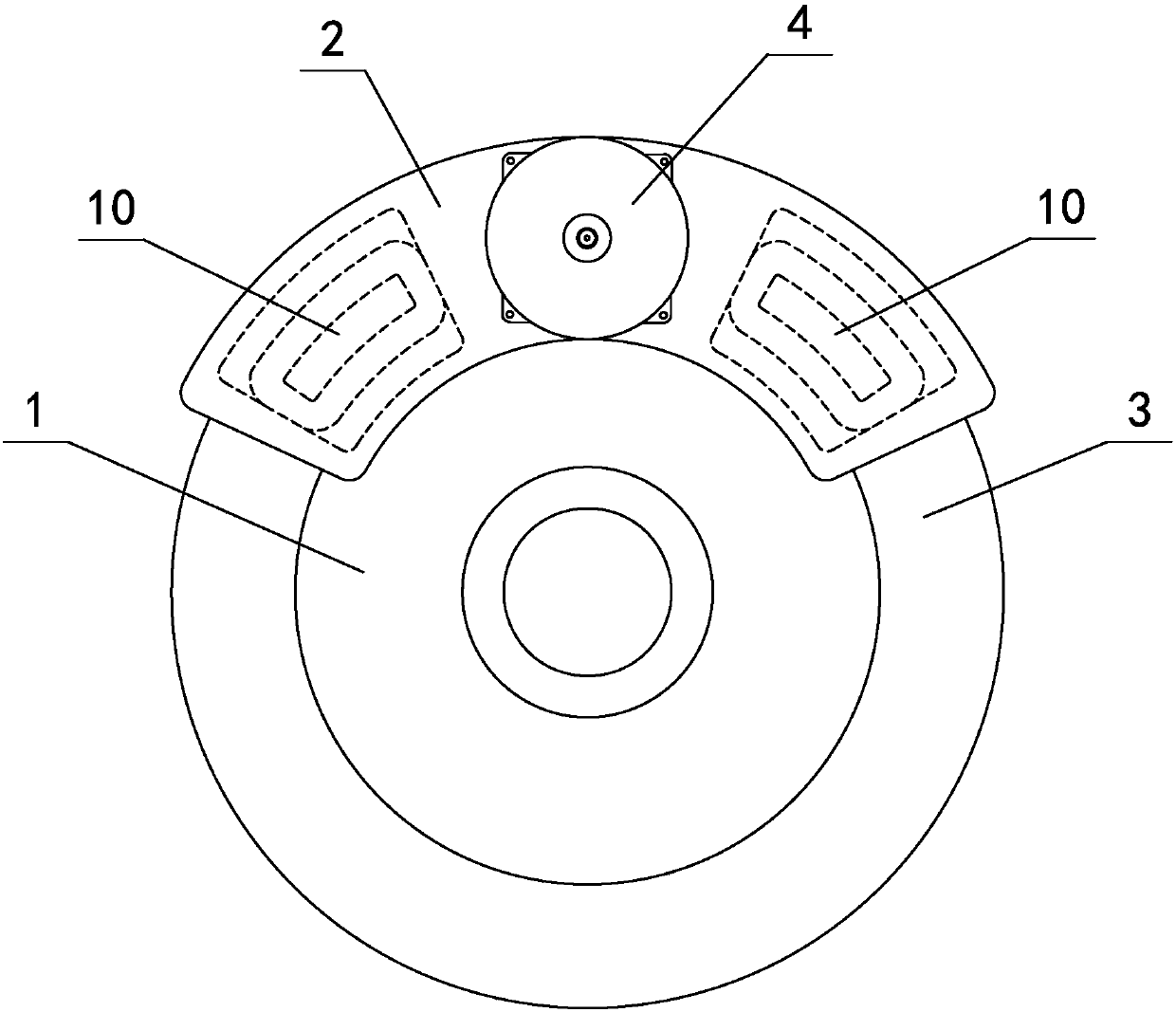

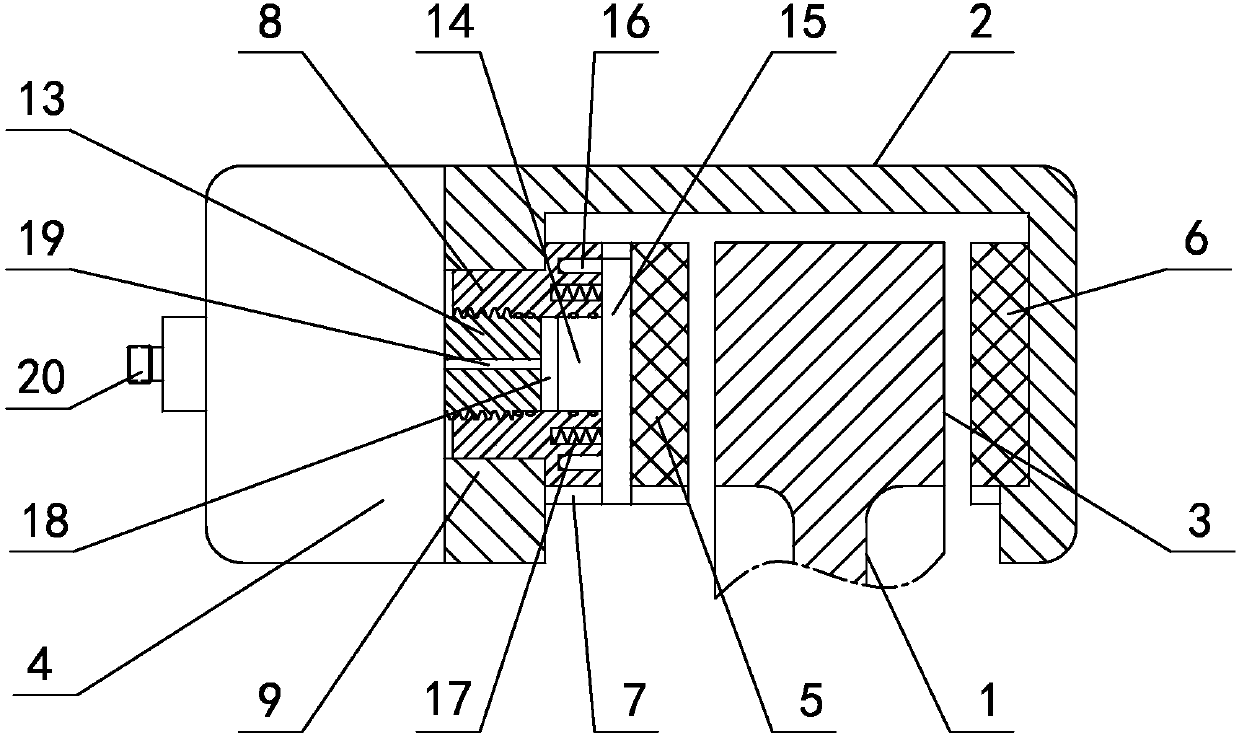

[0037] in such as figure 1 figure 2 In the shown embodiment 1, a brake device for an automobile includes a steel (magnetic material) brake disc 1 and a housing 2 arranged on the outer periphery of the brake disc and partially covering the brake disc. The cross-section of the outer edge of the moving disc is T-shaped, and the two sides of the brake disc are protrudingly provided with annular friction edges 3, and the annular friction edges are provided with textured patterns; the housing is provided with a brake motor 4 connected to the controller. The moving motor is a stepping motor, which is arranged at the upper middle position of the brake disc. The brake motor is connected with a floating caliper brake mechanism, and the caliper brake mechanism includes The movable brake pad 5 between them and the custom brake pad 6 arranged opposite to the other side of the brake disc, a top plate 7 is set between the brake motor and the dynamic brake pad, and a top block 8 is arranged...

Embodiment 2

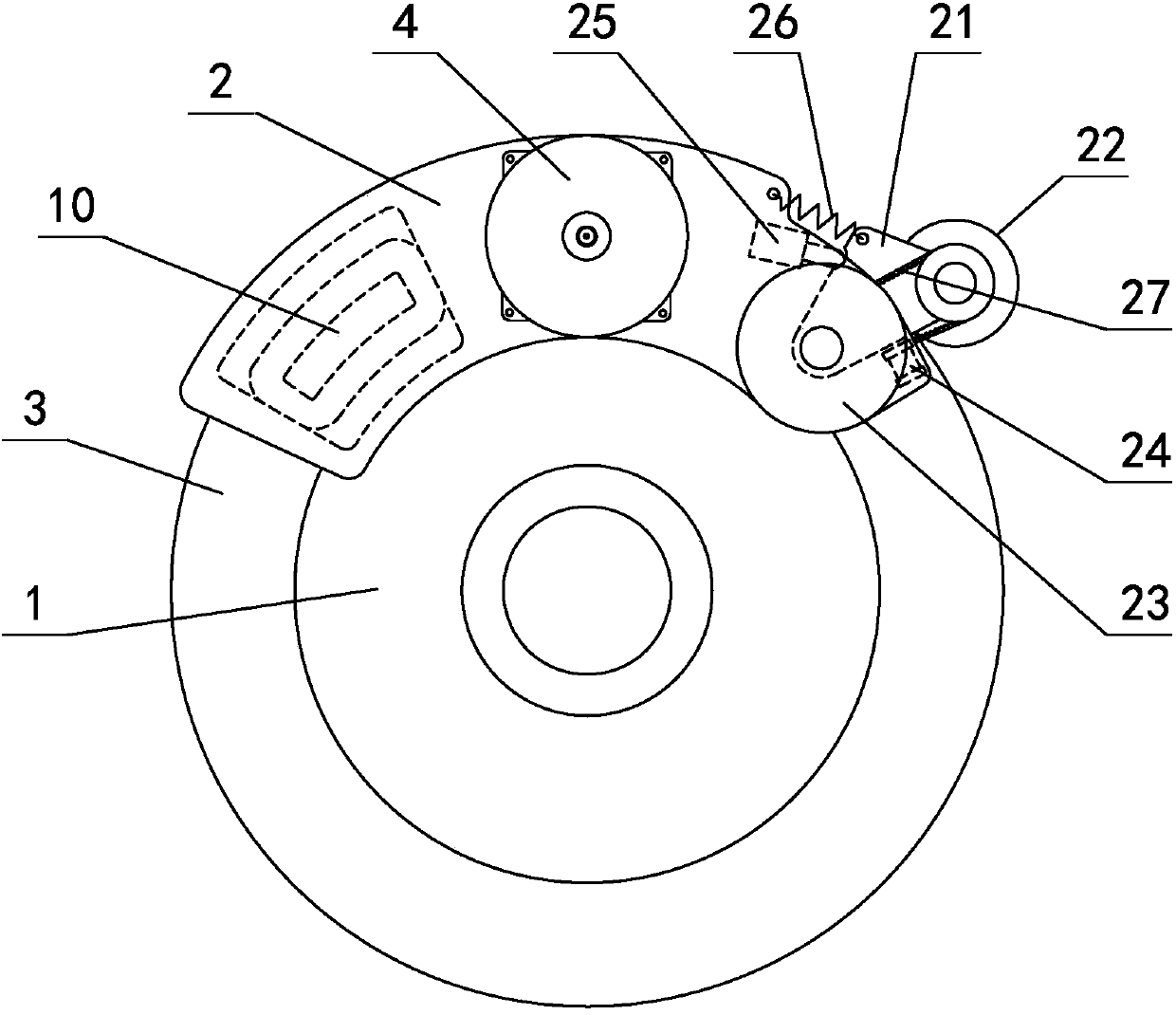

[0046] in such as image 3 Figure 4 In the shown embodiment 2, the outer circumferential surface of the brake disc is provided with a texture, the brake motor is arranged at the upper middle position of the brake disc, and a pair of electromagnetic brake blocks are provided on one side of the brake motor housing. 10. There is an auxiliary braking mechanism on the other side of the brake motor housing. The auxiliary braking mechanism includes a pair of steel (magnetic material) swing arms 21 arranged on both sides of the housing. The ends of the swing arms are connected by The bearing has a cylindrical friction wheel 22, and the housing is provided with a swing arm drive mechanism and a swing arm reset mechanism. The swing arm drive mechanism includes an electric drive mechanism and a hydraulic drive mechanism. The electric drive mechanism is arranged near the bottom of the swing arm The electromagnet 24, the hydraulic driving mechanism is a hydraulic ejector 25 arranged abov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com