Experimental use multi-row pressure testing rake device

A pressure measurement rake and experimental technology, which is applied in the field of fluid mechanics experimental test equipment, can solve the problems of test data interference, spatial resolution limitation, and limited application, so as to achieve small flow field interference, accurate test data, and improve spatial resolution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

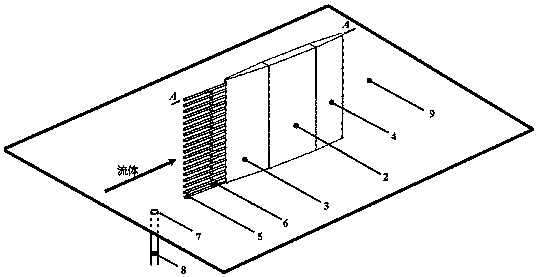

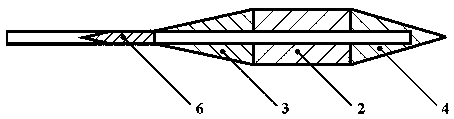

[0058] A multi-row pressure measurement rake device for experiments, installed on the surface of the model 9 to be tested, the multi-row pressure measurement rake device includes a plurality of single-row pressure measurement rakes, and the single-row pressure measurement rakes are distributed and installed on the model to be tested In the area where the velocity distribution of the boundary layer on the surface of 9 is the same, adjacent single rows of pressure measuring rakes are distributed along the spanwise direction of the surface of the model to be tested 9; the single row of pressure measuring rakes is provided with a total pressure discharge pipe 5, and The pipe 5 is composed of a row of vertically arranged ventilation pipes facing the direction of the fluid. The diameter of the ventilation pipes is D; the ventilation pipes are fixedly separated by a spacing adjustment block 6, and the height of the spacing adjustment block 6 is H; a separation block is arranged betwee...

Embodiment 2

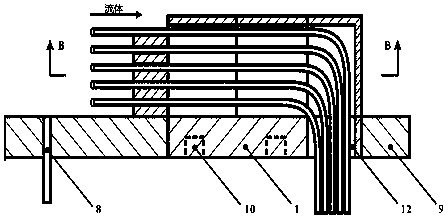

[0064] This embodiment is further optimized on the basis of embodiment 1, as figure 1 As shown, the multi-row pressure measurement rake device includes a single-row test rake; the single-row test rake includes a connection base 1 and a front edge rectification fixedly arranged on the connection base 1 in sequence, a main body rectification base 2, and a rear edge rectifier base 4; as figure 2 As shown, the connecting base 1 is fixedly embedded in the surface of the model to be measured 9 by connecting screws 10, and the surface of the connecting base 1 is flush with the surface of the model to be measured 9;

[0065] The connection base 1 may be provided with a through exhaust pipe outlet 12, and one end of the total pressure exhaust pipe 5 passes through the cavity formed by the front edge rectification base 3, the main body rectification base 2, and the rear edge rectification base 4 in sequence. Pass through the discharge pipe outlet 12 of the connection base 1; the other...

Embodiment 3

[0071]This embodiment is further optimized on the basis of embodiment 2, as Figure 4 As shown, the multiple rows of pressure measuring rakes include a single row of pressure measuring rakes R 1 and single-row pressure rake R 2 , single row pressure measuring rake R 1 and single-row pressure rake R 2 It is distributed along the surface span of the model 9 to be tested, and the interval between the single row of pressure measuring rakes is 1.5 times the thickness of the boundary layer; the single row of pressure measuring rakes R 1 The air pipe of the air pipe is directly set close to the surface of the model 9 to be tested; the single row of pressure measuring rakes R 2 The bottom end of the total pressure exhaust pipe 5 is connected to the surface of the model 9 to be tested through the partition block 11, and the height of the partition block 11 is (H+D) / 2, where H is the height of the spacing adjustment block 6; then the calculation is:

[0072]

[0073] When the mul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com