A kind of stable perovskite solar cell and preparation method thereof

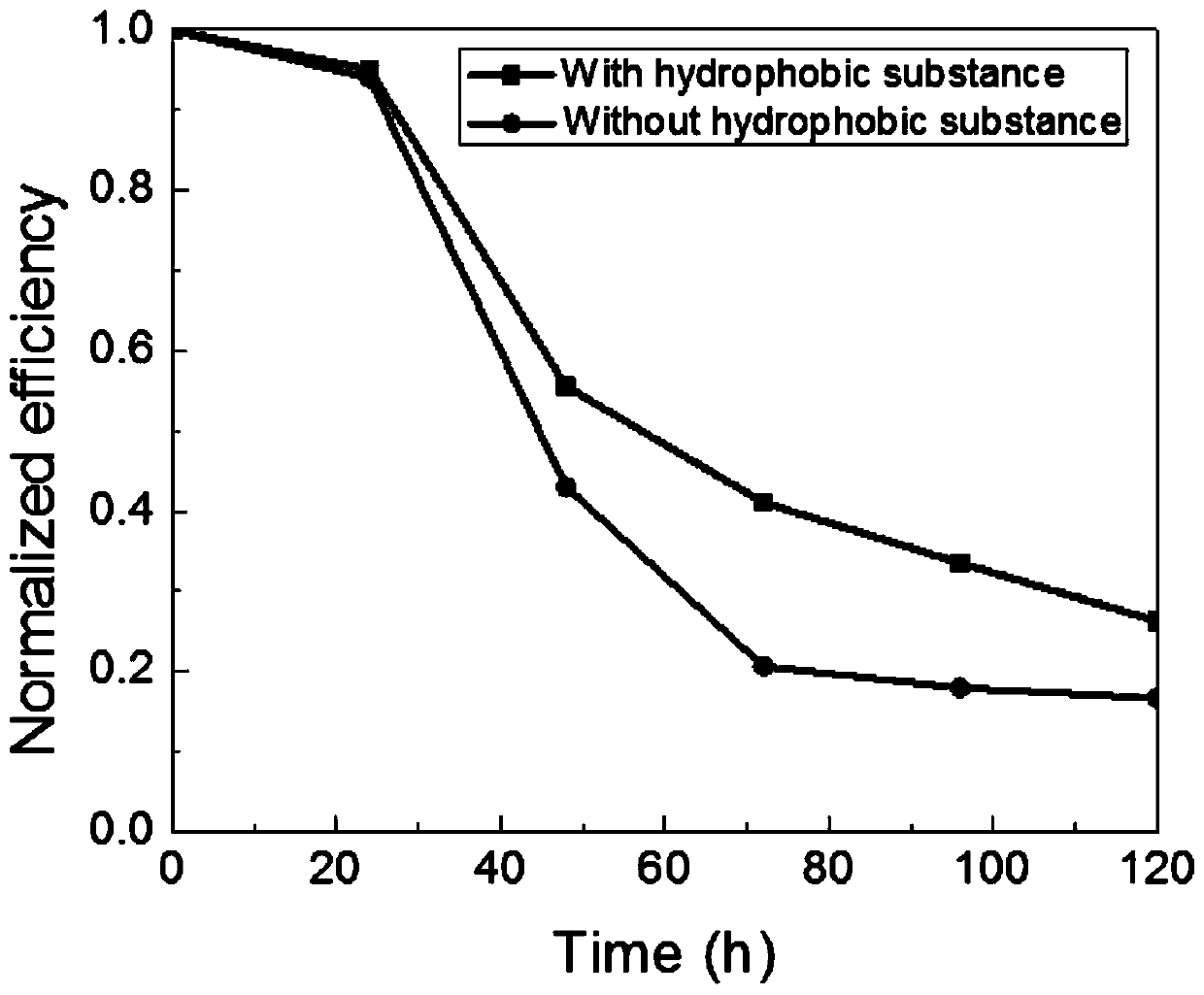

A solar cell and perovskite technology, applied in circuits, electrical components, photovoltaic power generation, etc., can solve the problems of easy water absorption, decomposition and instability of solar cells, and achieve the effects of improving cell stability, improving crystallization, and improving cell efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Take a piece of clean FTO conductive glass, laser-etch part of the conductive surface at the appropriate position, ultrasonically clean it with detergent, pure water, and ethanol for 10 minutes, then dry it with an air gun, and irradiate the cleaned FTO conductive glass with plasma surface 5min.

[0033] Place the conductive surface of the glass on the heating plate and heat it to 450°C within 30 minutes. When the temperature reaches 450°C, add a certain concentration of titanium isopropoxide isopropanol solution into the spray pen and spray it on the surface of the conductive glass. The whole process of spray pyrolysis takes 15 minutes. After completion, keep it warm for 10 minutes and cool it down to room temperature before taking it off.

[0034] Cut the FTO glass into a size of 1.25cm×2cm, paste it with adhesive tape, and then irradiate it with plasma surface treatment for 5 minutes. Take 100mg CH 3 NH 3 I and 289 mgPbI 2 Dissolve in 500 μl of N,N-dimethylforma...

Embodiment 2

[0040] Take a piece of clean FTO conductive glass, laser etch part of the conductive surface at a suitable position, clean it with detergent, pure water, and ethanol for 10 minutes, and then dry it with an air gun, and irradiate the cleaned FTO glass with plasma surface treatment for 5 minutes .

[0041] Place the conductive surface of the glass on the heating plate and heat it to 450°C for 30 minutes. When the temperature reaches 450°C, add a certain concentration of titanium isopropoxide and isopropanol solution into the airbrush. The whole process of spray pyrolysis takes 15 minutes, then keep it warm for 10 minutes, and then it can be removed after cooling to room temperature.

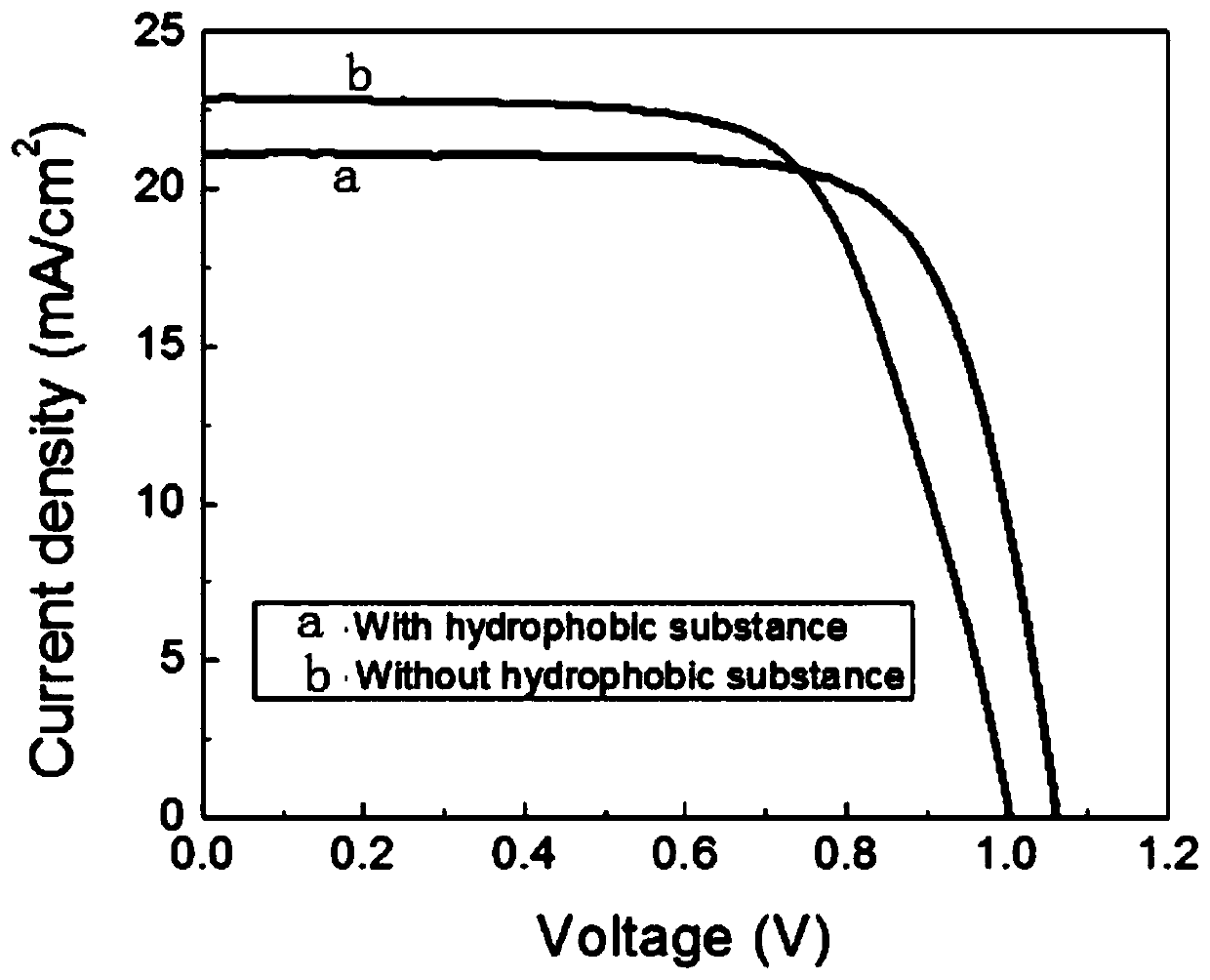

[0042] Cut the FTO glass into a size of 1.25×2cm, paste it with adhesive tape, and irradiate it with plasma surface treatment for 5 minutes. Take 100mg CH 3 NH 3 I and 289 mg PbI 2 Dissolve in 500 μl N,N-dimethylformamide (DMF), add amino silicone oil, the content is less than 5wt% of the perov...

Embodiment 3

[0048] Take a piece of clean FTO conductive glass, laser-etch part of the conductive surface at the appropriate position, ultrasonically clean it with detergent, pure water, and ethanol for 10 minutes, then dry it with an air gun, and irradiate the cleaned FTO conductive glass with plasma surface 5min.

[0049] Place the conductive surface of the glass on the heating plate and heat it to 450°C within 30 minutes. When the temperature reaches 450°C, add a certain concentration of titanium isopropoxide isopropanol solution into the spray pen and spray it on the surface of the conductive glass. The whole process of spray pyrolysis takes 15 minutes. After completion, keep it warm for 10 minutes and cool it down to room temperature before taking it off.

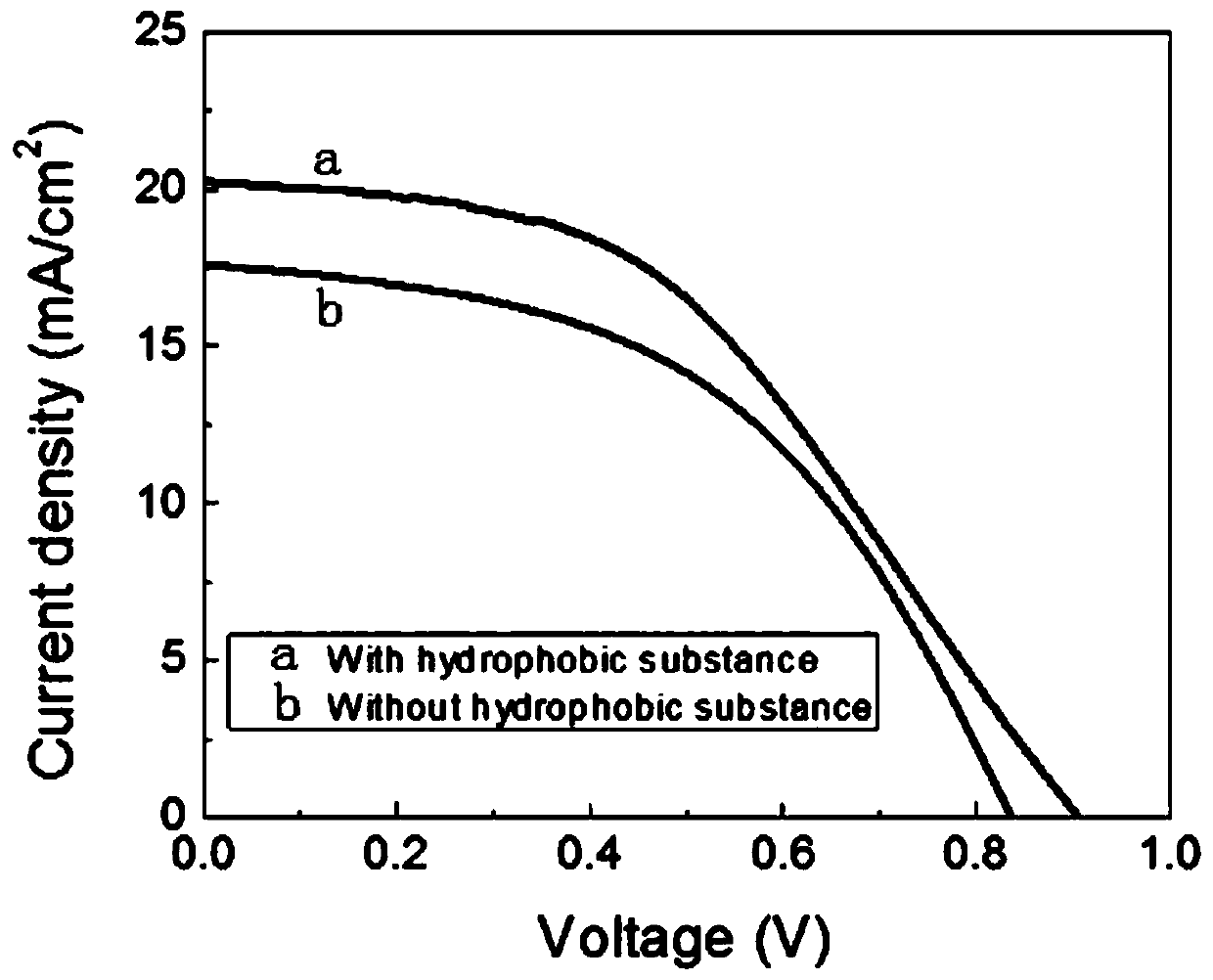

[0050] Cut the FTO glass into a size of 1.25cm×2cm, paste it with adhesive tape, and then irradiate it with plasma surface treatment for 5 minutes. Take 100mg CH 3 NH 3 Br, 289mg PbI 2 Dissolve in 500 μl N,N-dimethylformamide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com