Tool for welding assembly of end socket and flange

A flange welding and head technology, which is applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems that the welding and assembly quality of the head and flange cannot be satisfied.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

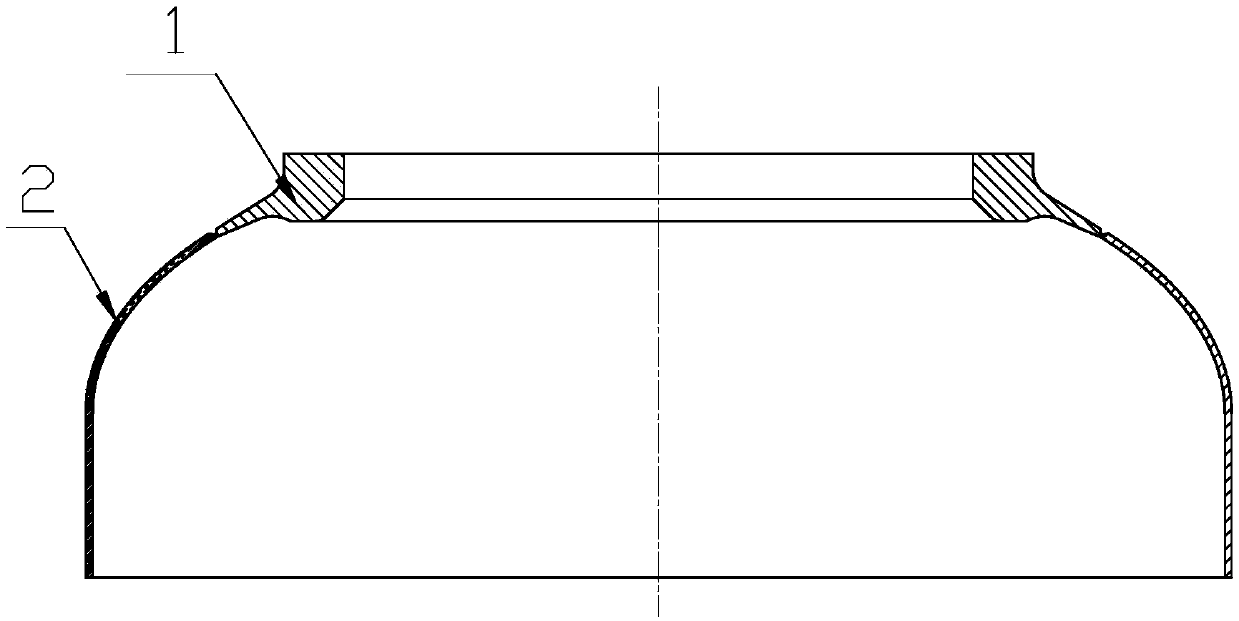

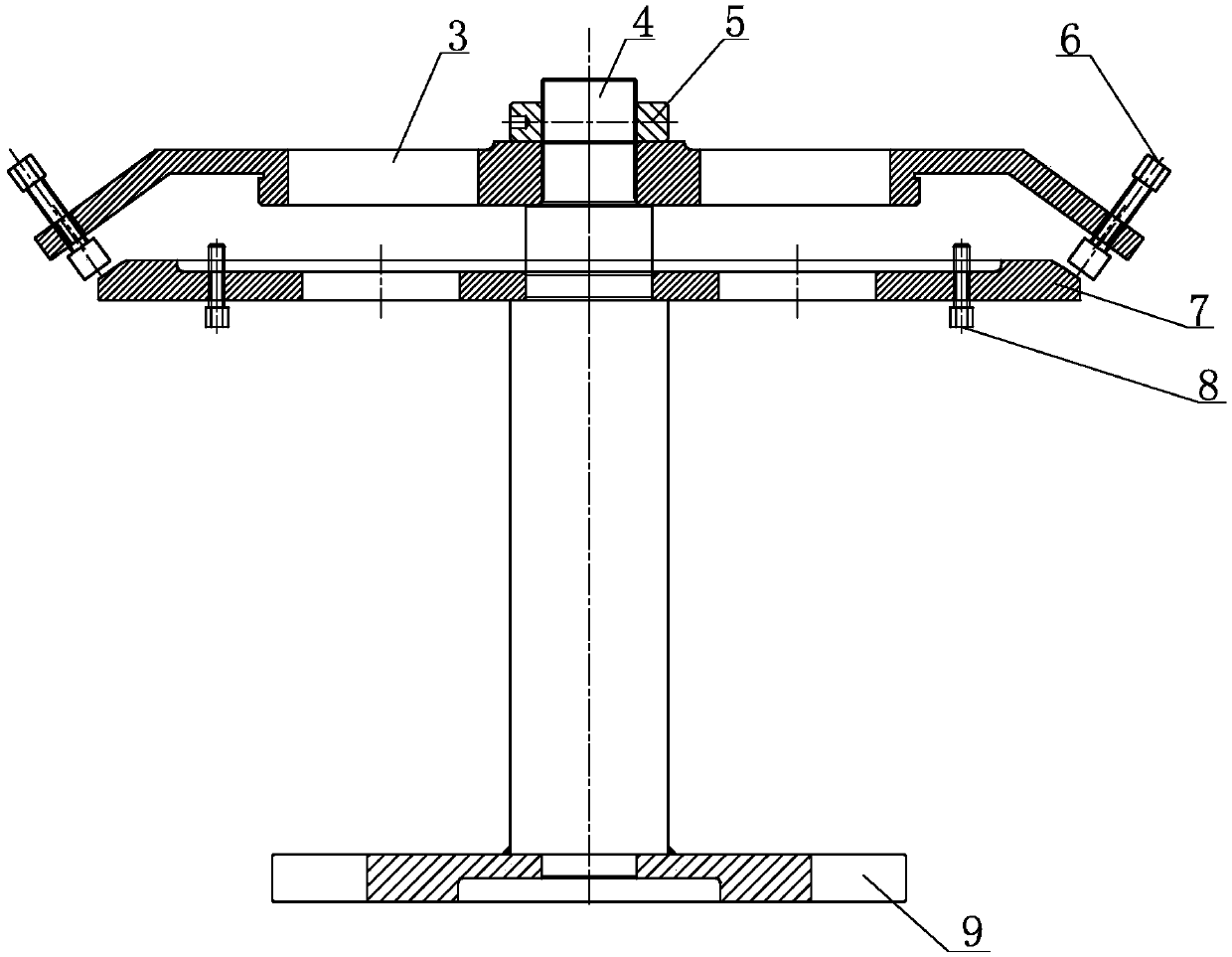

[0018] The invention designs and manufactures welding and assembly tooling of different specifications for different sizes of heads and flanges.

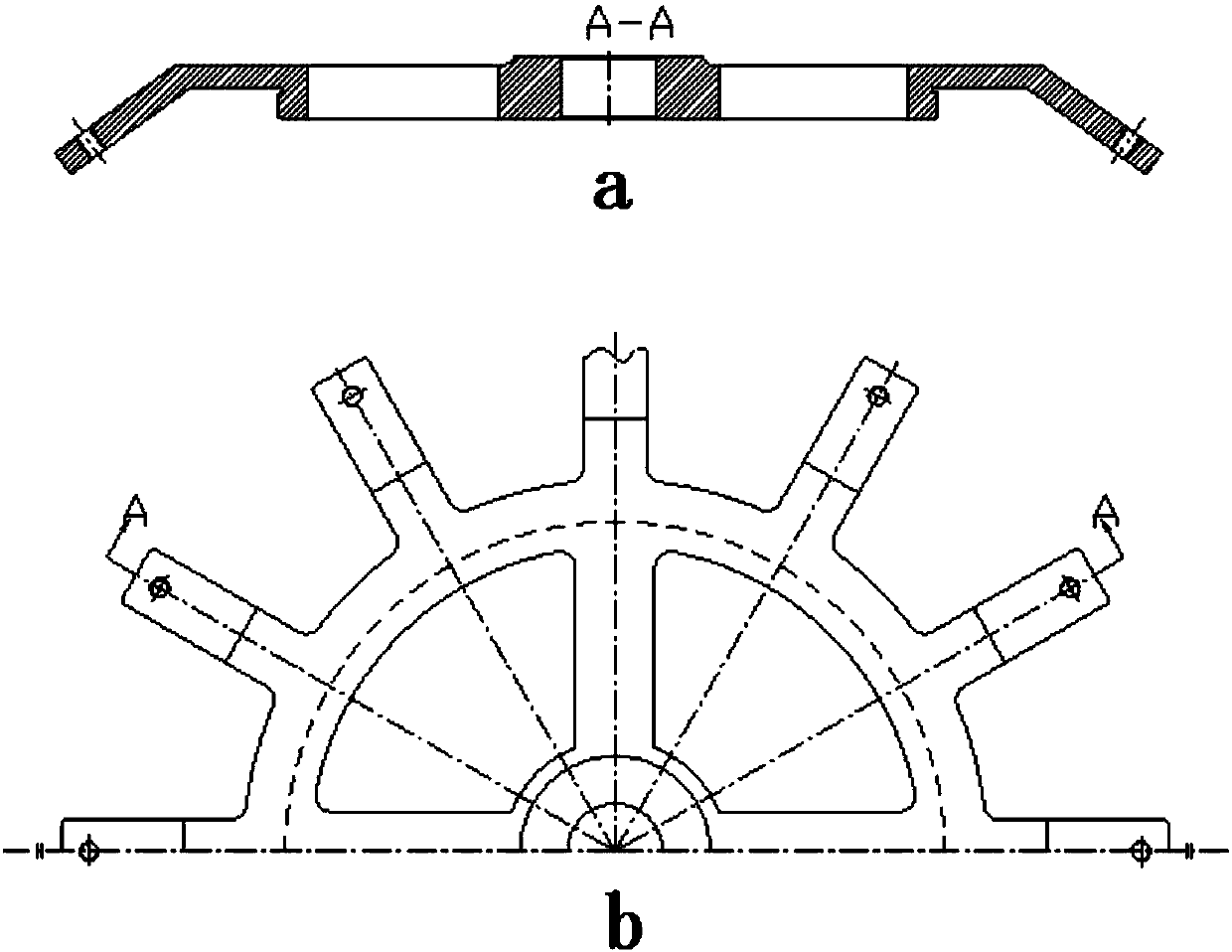

[0019] This embodiment is a head and flange welding assembly tool, including a pressure plate 3, a main shaft 4, a compression nut 5, a misalignment adjustment bolt 6, a backing plate 7, a lift adjustment bolt 8 and a bottom plate 9. The pressure plate 3 and the backing plate 7 are set on the upper part of the main shaft, and are fastened by the compression nut 5 ; the pressure plate 3 is located above the backing plate 7 . The ends of each mounting rod located on the circumference of the pressure plate are respectively equipped with a misalignment adjustment bolt 6, and the tops on each misalignment adjustment bolt correspond to the head supporting surface on the edge of the upper surface of the backing plate 7 circumference. The lower end of the main shaft 4 is fixed on the center of the bottom plate 9 . Lifting amount adjusting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com