Powder spraying device provided with rotating storing tables for ceramic production

A technology for placing a table and spraying powder, which is applied in the field of powder spraying devices, can solve the problems of low powder spraying efficiency and insufficient powder spraying, and achieve the effect of improving powder spraying efficiency, shortening powder spraying time, and achieving comprehensiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

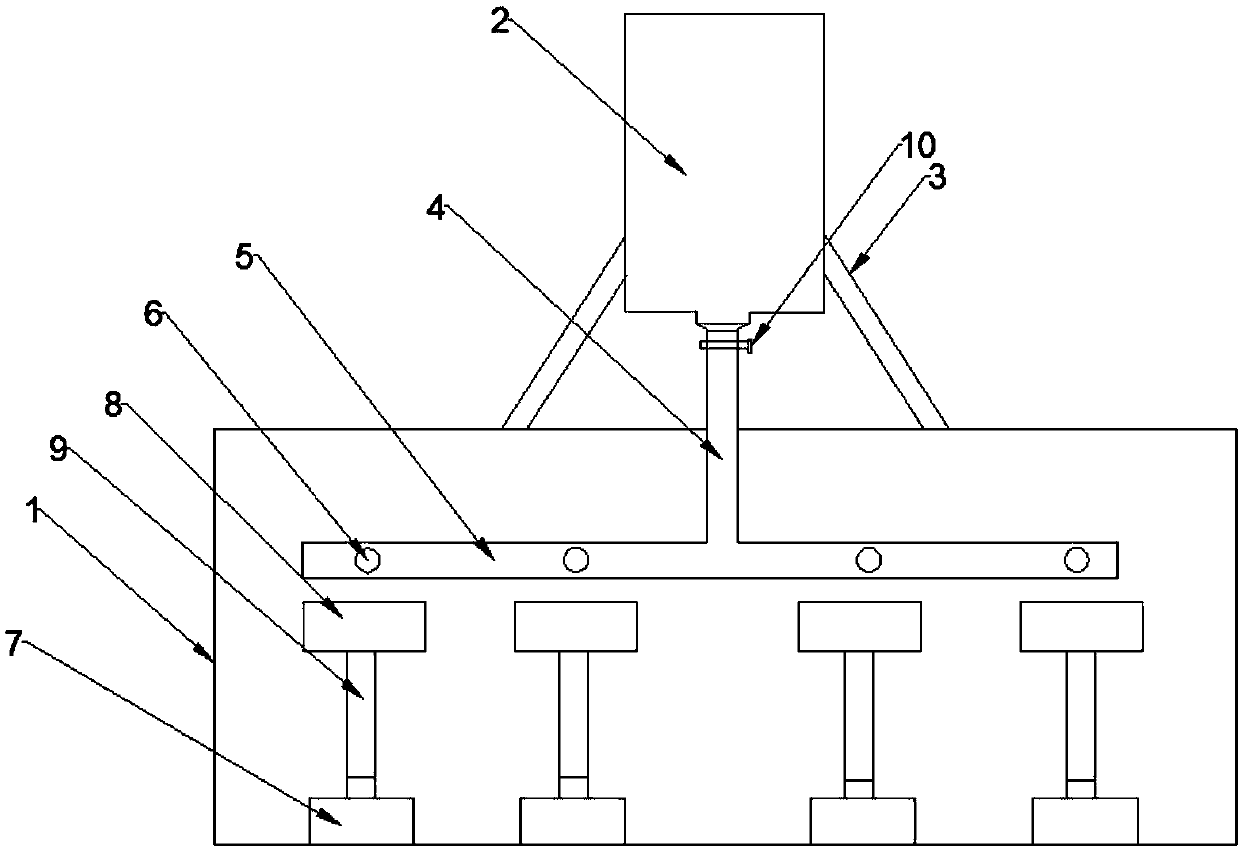

[0016] Such as figure 1 As shown, a powder spraying device for ceramic production with a rotary placement table includes a housing 1, and the housing 1 is provided with a dodge door,

[0017] The bottom of the housing 1 is uniformly provided with a plurality of rotating motors 7, the output shafts of the rotating motors 7 are fixedly connected with a rotating rod 9, and the upper end of the rotating rod 9 is fixedly connected with a placing table 8, and the centers of the placing table 8 are on the same straight line. The powder spraying assembly is provided in front of the straight line where the placing table 8 is located; the powder spraying assembly includes a powder material cylinder 2, and the powder material cylinder 2 is fixed on the top of the housing 1 through a fixed rod 3. The fixed rod 3 includes three fixed rods 3, and the three fixed rods The included angle between the rods 3 is 120°, the powder outlet at the bottom of the powder barrel 2 is connected with a fir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com