Powder spraying device capable of repeatedly utilizing raw materials for ceramic production

A powder spraying and raw material technology, applied in the direction of ceramic molding machines, manufacturing tools, etc., can solve the problems of powder waste, low powder spraying efficiency, and insufficient powder spraying, so as to shorten the powder spraying time, improve the powder spraying efficiency, and uniform The effect of dusting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

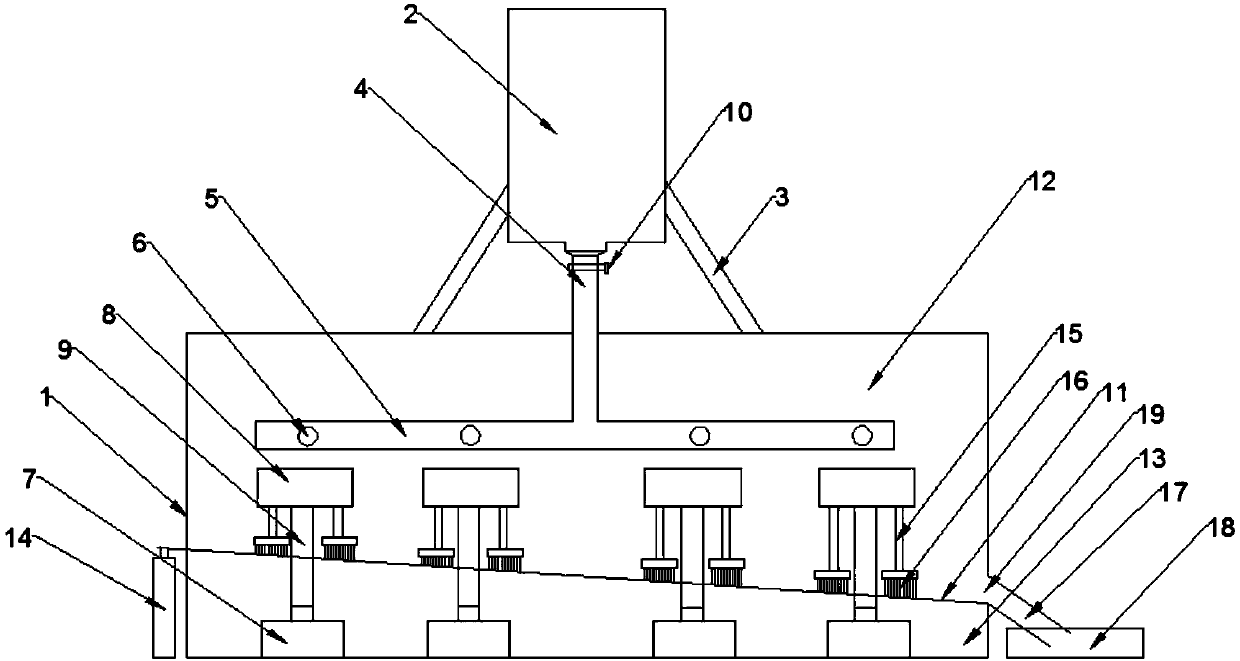

[0018] Such as figure 1 As shown, a reusable powder spraying device for raw materials used in ceramic production includes a housing 1, and the housing 1 is provided with a dodge door,

[0019] Described shell 1 is provided with inclined plate 11, and one end of inclined plate 11 stretches out shell 1, and the part below inclined plate 11 protruding shell 1 is provided with vibration motor 14, and inclined plate 11 is shell 1 from top to bottom. The bottom is divided into a powder spraying chamber 12 and an installation chamber 13 in turn; the installation chamber 13 is provided with a plurality of rotating motors 7, the output shafts of the rotating motors 7 are fixedly connected with a rotating rod 9, and the rotating rod 9 runs through the inclined plate 11 and extends into the In the powder spraying room 12, the upper end of the rotating rod 9 is fixedly connected with a placement table 8, and the bottom of the placement table 8 is symmetrically provided with a cleaning dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com