Battery electric vehicle high-voltage power-on and power-off control method

A pure electric vehicle, high-voltage power-on technology, applied to electric vehicles, electrical devices, vehicle components, etc., can solve the problems of damaged batteries and insufficient protection measures, and achieve the effect of prolonging service life and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention is described in detail below in conjunction with the embodiment that accompanying drawing provides:

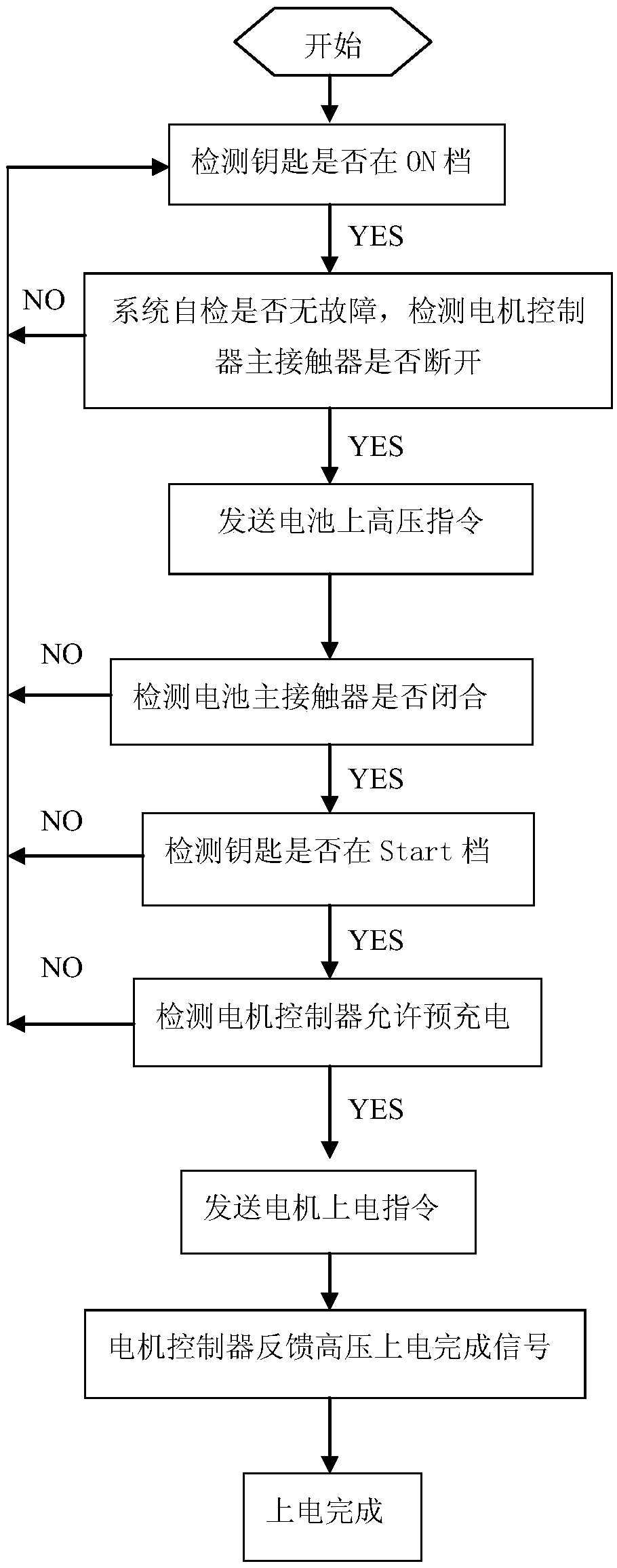

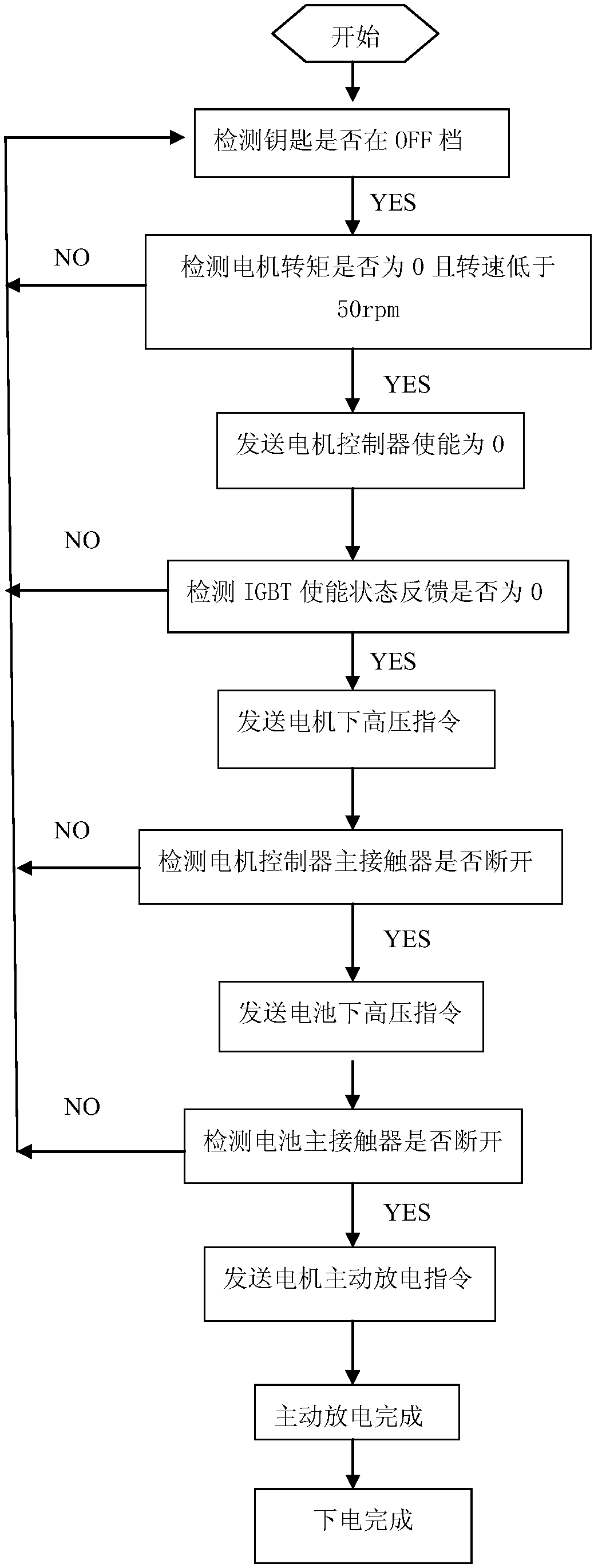

[0042] see figure 1 and image 3 , a pure electric vehicle high-voltage power-on control method, comprising the following steps:

[0043] 1) Detect whether the key is in the ON gear, if the key is in the ON gear, go to the next step;

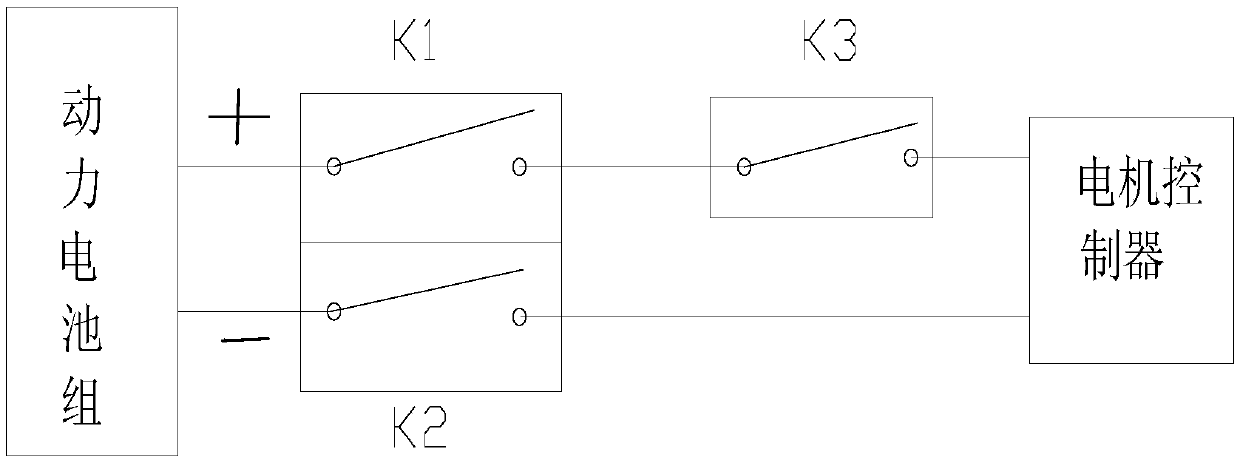

[0044] 2) Whether the system self-inspection has no faults, check whether the main contactor K3 of the motor controller is disconnected; if the system self-inspection is not faulty and the main contactor K3 of the motor controller is disconnected, then enter the next step; if the system self-inspection is faulty Or the main contactor K3 of the motor controller is not disconnected, then return to the previous step;

[0045] 3) The vehicle controller sends the battery high voltage command;

[0046] 4) Detect whether the positive switch K1 and the negative switch K2 of the battery main contactor are closed, if close...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com