Low noise cartridge receiver and control plane for duct type vertical take-off and landing air vehicle

A vertical take-off and landing, aircraft technology, applied in the field of unmanned aerial vehicles, to achieve broad application prospects, good acoustic quality, noise suppression effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

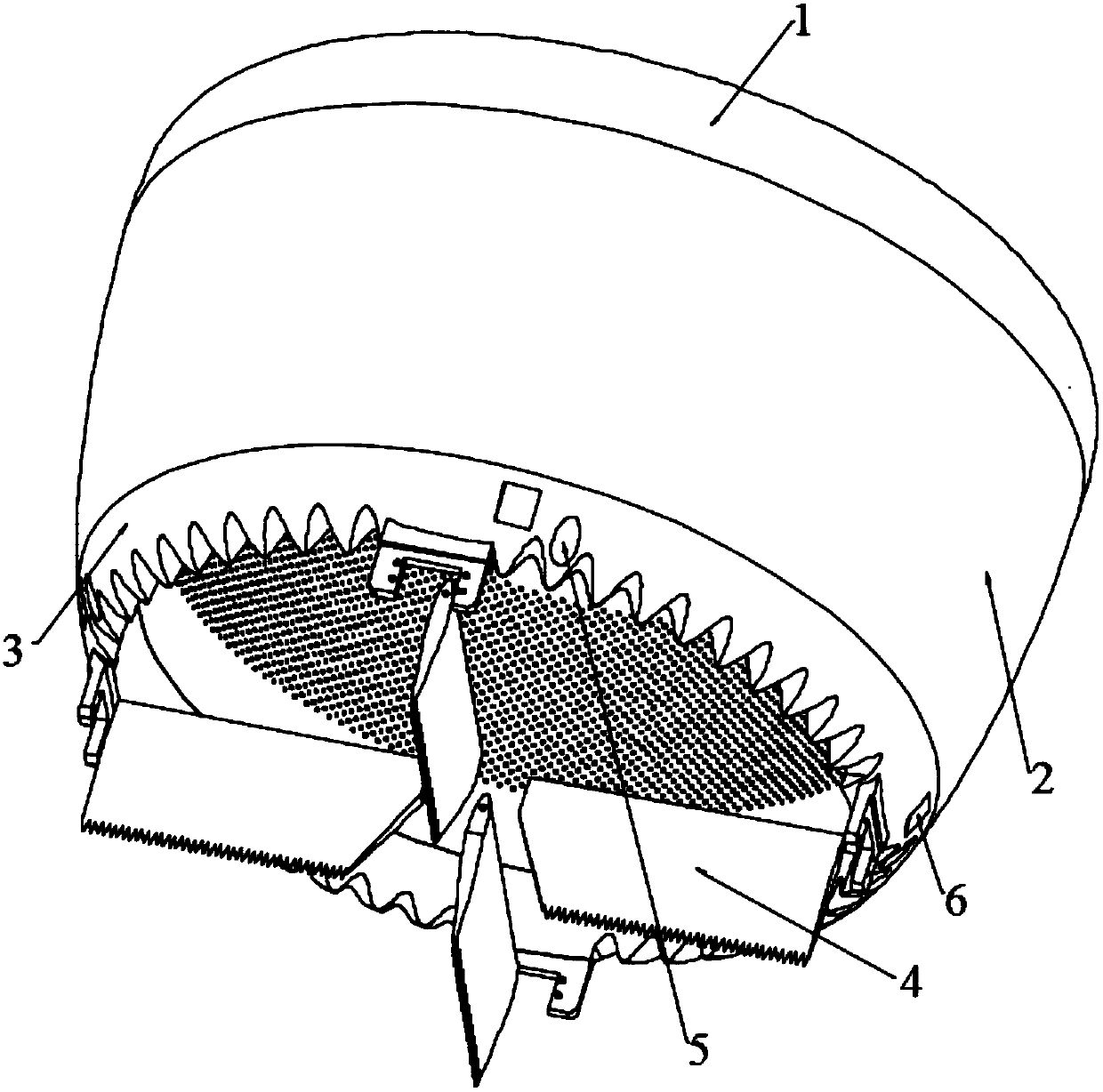

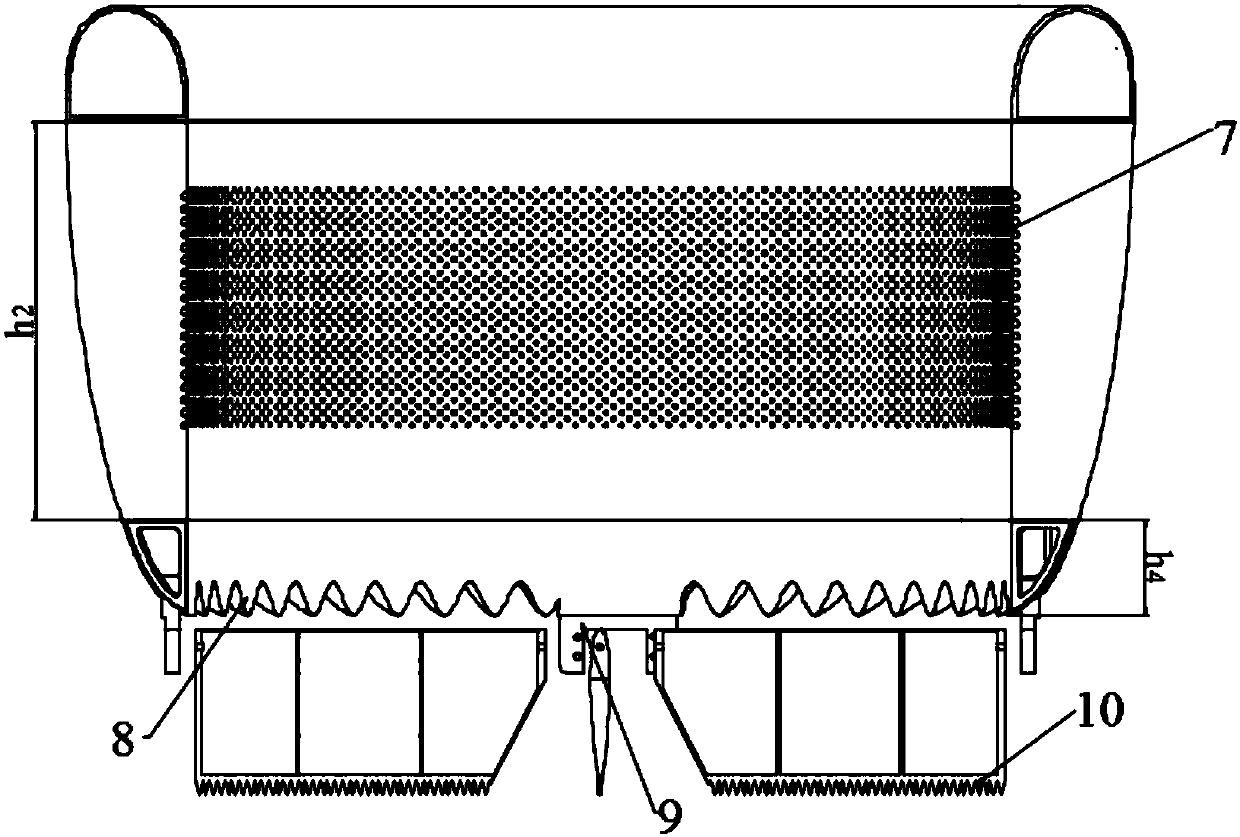

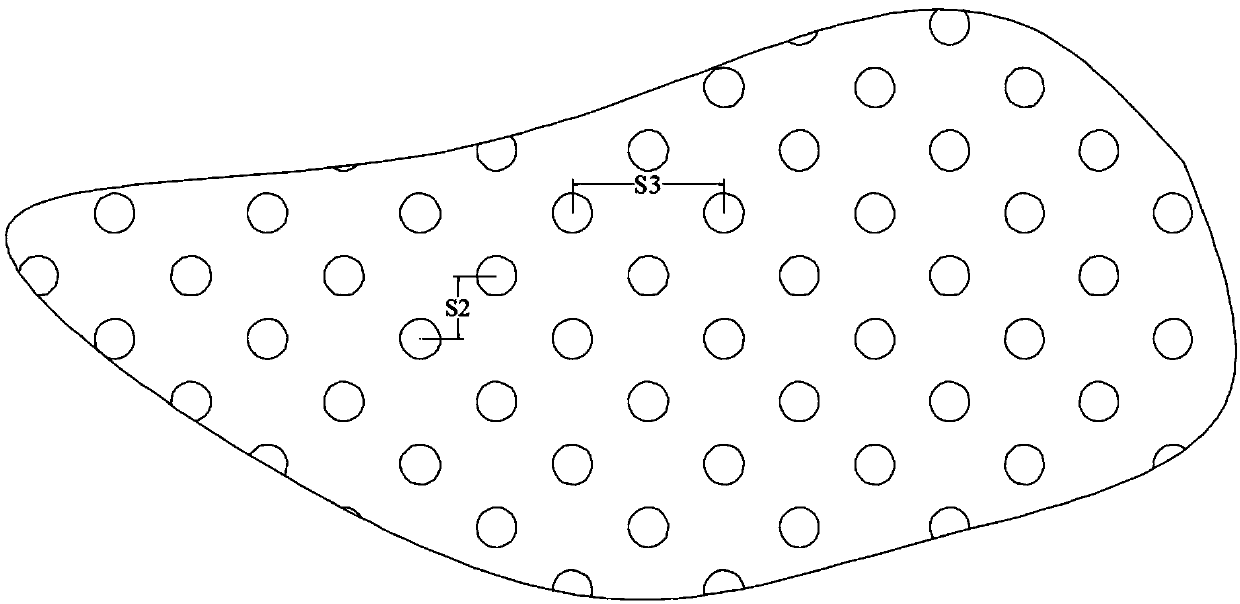

[0023] see Figure 1-Figure 7 , the present invention includes a lip ring, a casing main body, a serrated bottom ring and a tail guiding rudder surface. The lip ring, receiver body and serrated bottom ring are arranged in sequence from top to bottom. The tail guiding rudder surface is installed inside the serrated bottom ring, and triangular serrations are distributed on the tail edge. The main body of the casing is made of EPP foam with a foaming rate of 20% to 40%. The lip ring, the main body of the casing and the serrated bottom ring can be connected and fixed by using long bolts and nuts through four screw holes. The main body of the casing made of EPP foam can block the noise of the propeller, and the noise generated by the propeller can be more effectively absorbed after the casing is processed; Reduce the jet noise of the ducted aircraft; the fine sawtooth structure at the trailing edge of the tail guide surface widens the wake area and accelerates the breakup of the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com