Paper board packaging box with buffering mechanism

A cushioning mechanism and packing box technology, applied in the direction of packaging, transportation and packaging, and containers to prevent mechanical damage, etc., can solve the problems of inconvenient use, waste of inflatable bags, etc., and achieve the effects of preventing loss, convenient operation, and preventing movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

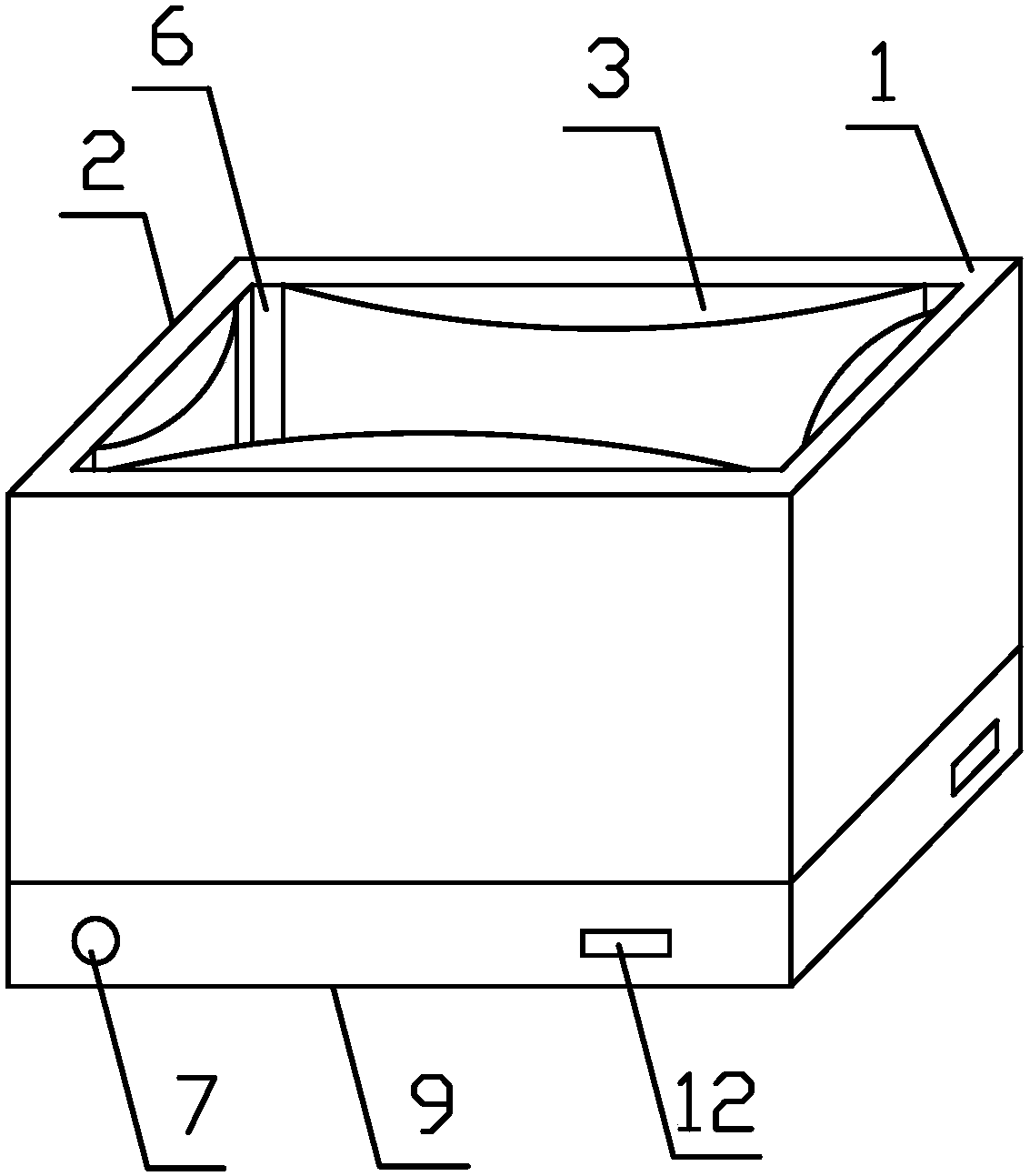

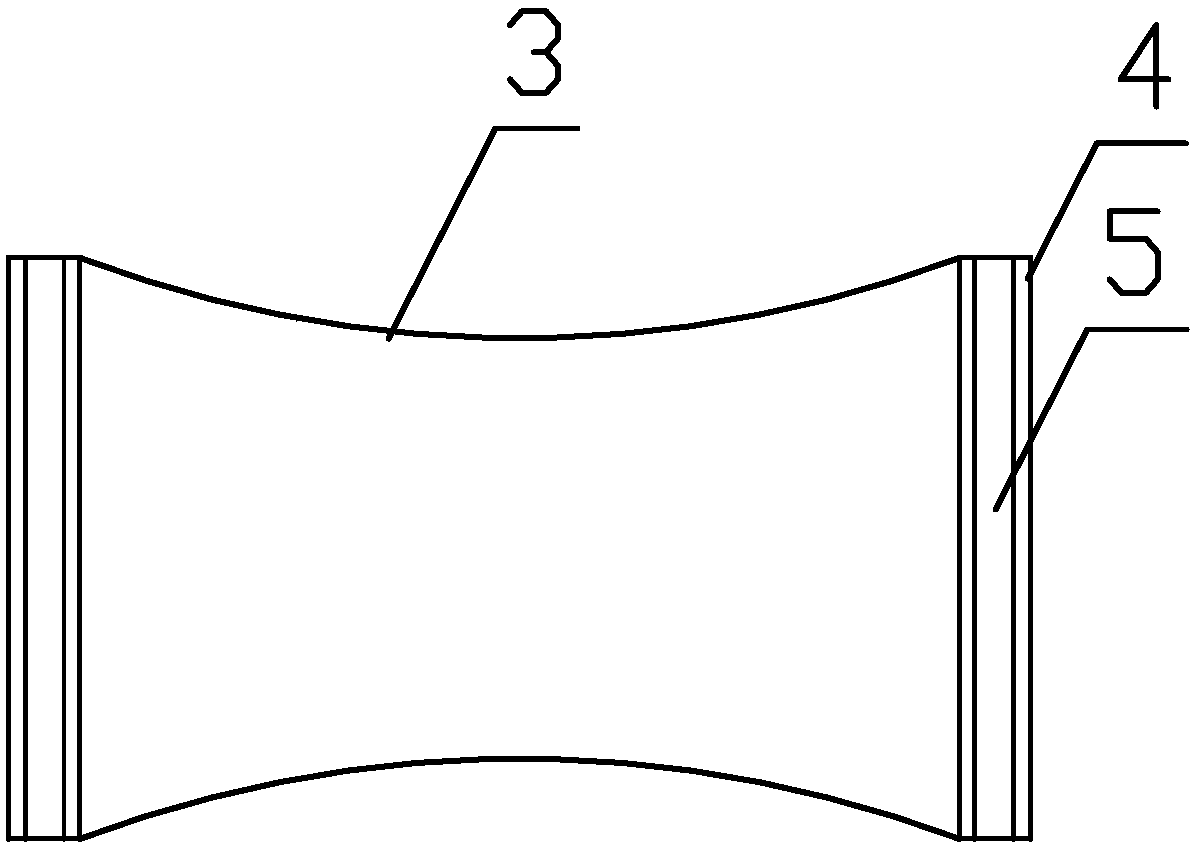

[0029] Such as Figure 1~4 As shown, the cardboard packaging box with buffer mechanism of the present invention includes corrugated cardboard 1, and the side wall of the carton 2 is formed by the end-to-end connection of the corrugated cardboard 1, and also includes an inflatable buffer bag 3. End is provided with fixed plate 4, and described fixed plate 4 is provided with the first nylon self-adhesive tape 5 on one plate surface; 5 Adapted second nylon self-adhesive tape 6, the inflatable buffer tape 3 is adhered and fixed on the corresponding corrugated cardboard 1 through the first nylon self-adhesive tape and the second nylon self-adhesive tape 6; the outer wall of the corrugated cardboard 1 An inflation and deflation nozzle 7 communicating with the inflation buffer bag 3 is also provided.

Embodiment 2

[0031] Further improvement on the basis of Embodiment 1, the fixing plate 4 is made of hard cardboard. The first nylon self-adhesive tape 5 is provided on the mutually parallel two board surfaces of the fixed plate 4; the third nylon self-adhesive tape 8 is also provided on the second nylon self-adhesive tape 6, and the third nylon self-adhesive tape 8 is provided. The belt 8 is adhesively adapted to the second nylon self-adhesive belt 6 or the first nylon self-adhesive belt 5 .

Embodiment 3

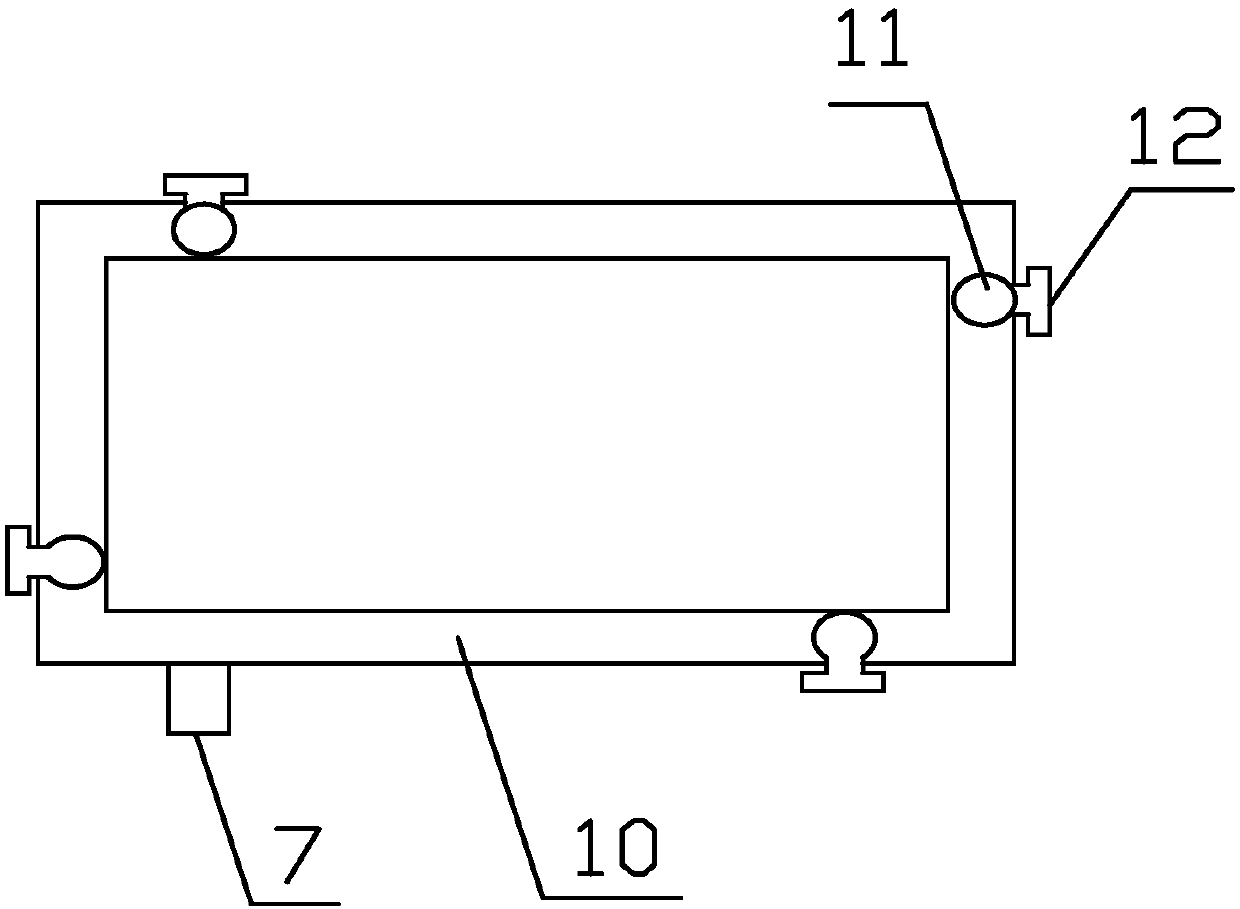

[0033] Further improvement on the basis of Embodiment 2, the bottom of the carton 2 is further provided with a hollow base 9, and the base 9 is provided with an air intake pipeline for connecting the inflation and deflation nozzle 7 and the inflation buffer bag 3 . The air intake pipeline includes an air intake main pipeline 10 and an air intake branch pipeline 11; the input end of the air intake main pipeline is connected with the inflation nozzle 7; the air intake main pipeline 10 is provided with the inflation buffer bag 3 connected to the air intake branch pipeline 11, the air intake branch pipeline 11 is provided with a control valve 12, and the control valve 12 protrudes from the outer wall of the base 9. Described base 9 is made of PVC rigid plastic plate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com