Automatic truck loading machine

A car loader, automatic technology, applied in conveyors, loading/unloading, transportation and packaging, etc., can solve the problems of large space occupation, low work efficiency, high labor intensity, etc., and achieve low equipment cost and high work efficiency. 、Applicable to the effect of a wide range of venues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

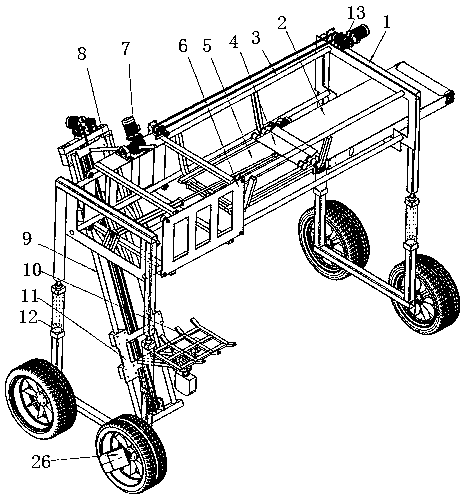

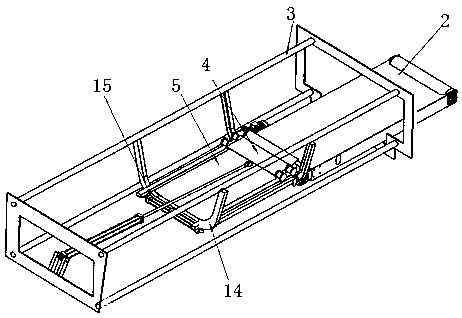

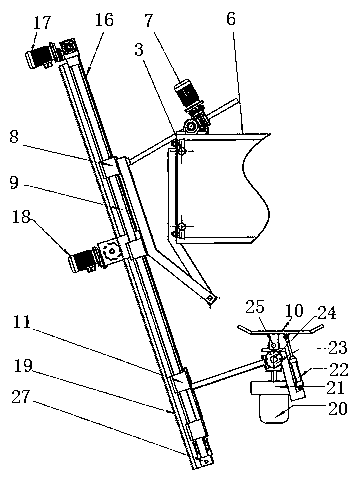

[0007] The embodiment is described in detail in conjunction with the accompanying drawings. The present invention is to install two groups of horizontal guide rails 3 on both sides above a movable frame 1, and a pocket door 5 is arranged in the middle of the frame below the horizontal guide rails. There are bag-dropping tracks 14 corresponding to each other on both sides between the bag-dropping door, an opening and closing cylinder 15 is provided on the bag-dropping door, and a horizontal tackle 6 cooperating with the bag-dropping door is installed downward on the horizontal guide rail. A pulley motor 13 is installed on the frame, and a conveyor belt 2 is provided on the frame from one end of the pulley motor to the bag-dropping door, and a drag bag mechanism 4 is installed on the conveyor belt at the other end of the frame, on the horizontal pulley of the drag mechanism A vertical guide rail 9 is installed from top to bottom with fixed frame 8, and the lifting tackle 11 drive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com