Array-tube-type weir gate

A technology of tubular and weir gates, which is applied to the liquid level control device of the channel, array tubular weir gates. It can solve the problems of slow execution speed, affect the quality of work, and reduce the service life of the motor, and achieve the effects of various structural combinations, wide range of water level adjustment, and prevention of sludge accumulation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

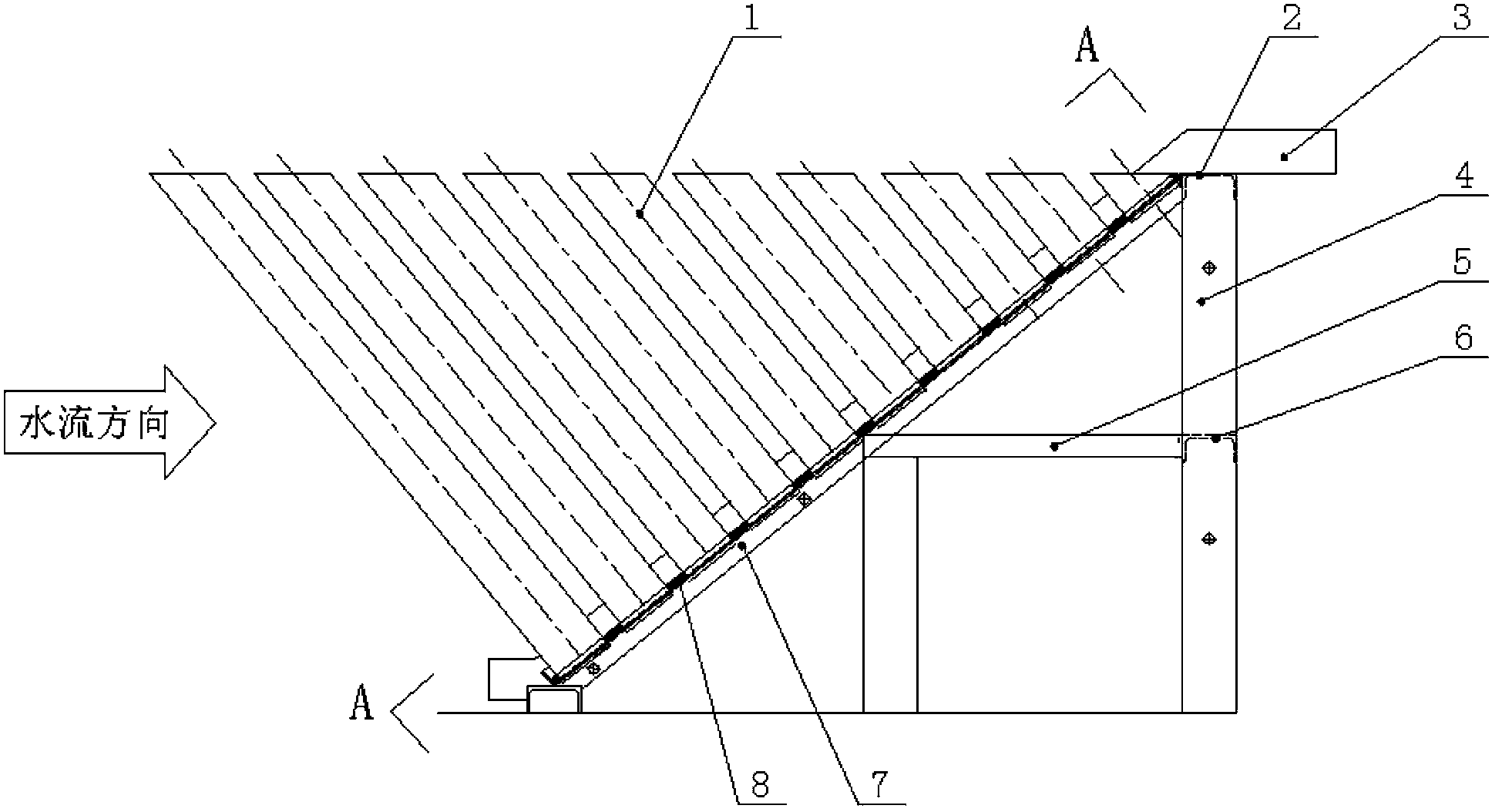

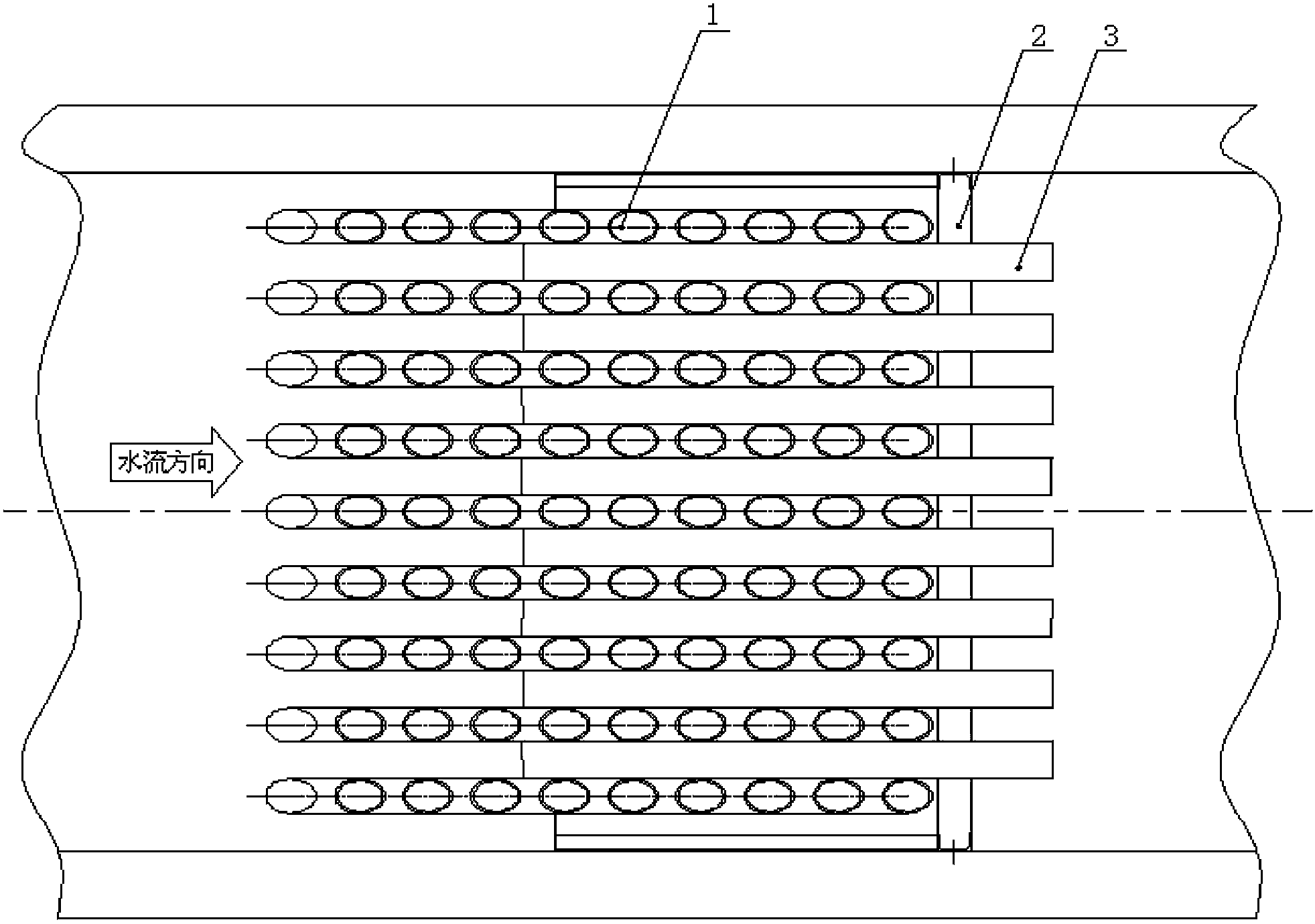

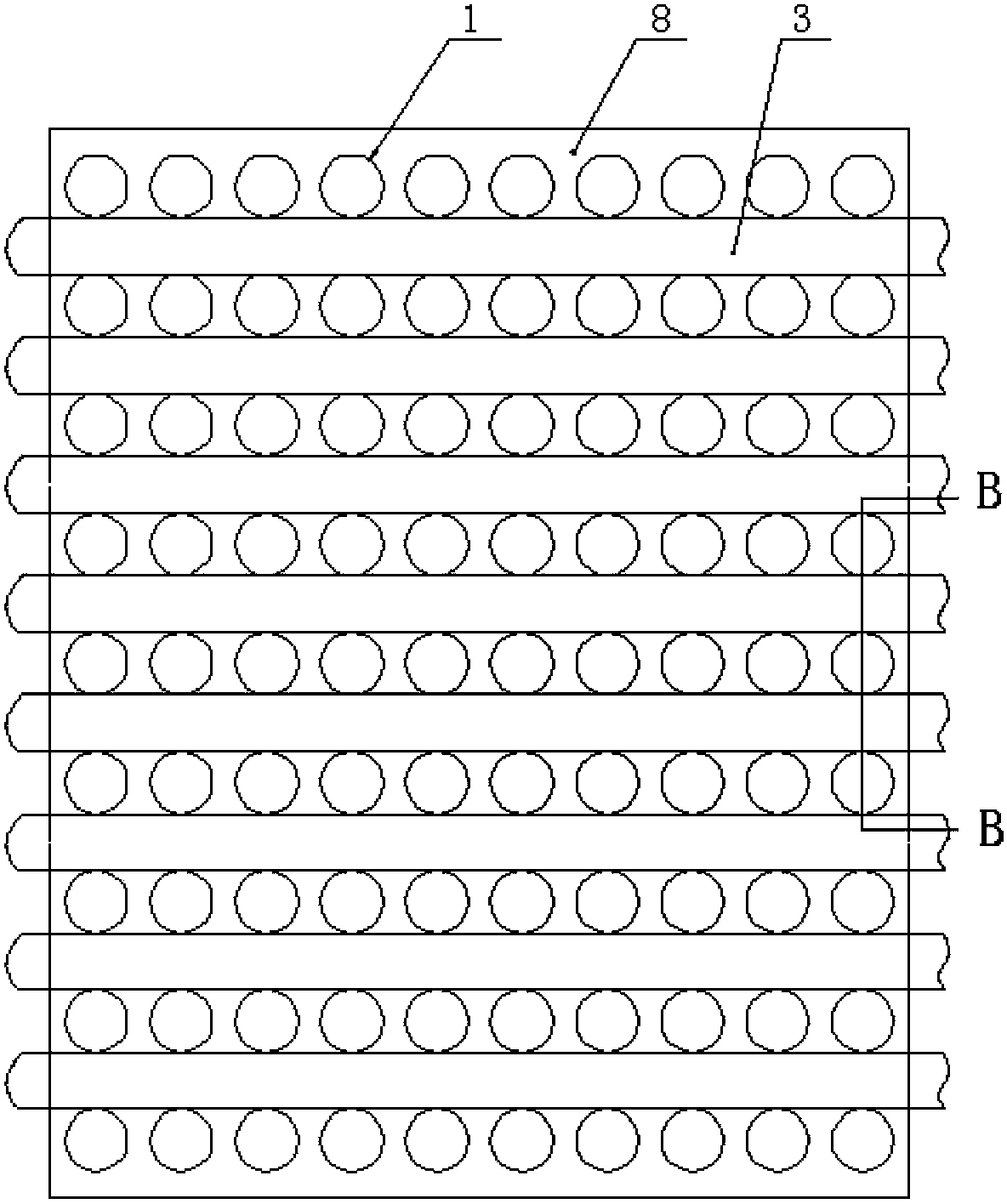

[0035] An array tubular weir gate, such as figure 1 , figure 2 The direction of water flow shown is horizontal, including slant plate 8, frame 7 and quick drain pipe 1. The frame is made of channel steel and angle steel. The frame is tilted and fixed in the water channel, the side lower side of the inclined plate is sealed and fixed with the bottom of the water channel, the two sides of the inclined plate are sealed and fixed with the two side walls of the water channel, and the inclined plane of the inclined plate is sealed and fixed at intervals. A plurality of rapid drain pipes, the horizontal inclination angle of the plurality of rapid drain pipes is 30°-150°, the upper end of the rapid drain pipes is the drain inlet, and the end of the quick drain pipes below the inclined plate is the drain outlet, and the quick drain pipes The vertical height is designed according to the water storage height requirements of the canal.

[0036] The quick drain pipe is a quick drain pip...

Embodiment 2

[0041]In order to meet the number of fast drain pipes required for drainage under the condition of limited length, so that the weir gate has a larger adaptability range, a flat plate 10 is installed horizontally on the upper part of the inclined plate described in Embodiment 1, and the sealing plate 10 is fixed on the flat plate. There are a plurality of extended drain pipes arranged at even intervals and having the same inclination angle as the fast drain pipe installed on the sloping plate. The plates are sealed and firmly connected to the two side walls of the water channel.

Embodiment 3

[0043] The vertical heights of the quick drain pipes are different, and the number of quick drain pipes participating in drainage is different at different liquid level heights, so as to adjust and control the discharge flow, such as Image 6 As shown, the height of the fast drain pipe fixed at the front of the swash plate is lower than the height of the rear side of the swash plate, and the height of the quick drain pipe in the middle of the swash plate can also be higher than that of the quick drain pipes on both sides.

[0044] Moreover, because the new arrayed weir gate can be sealed with the bottom and the surrounding of the canal, and the quick discharge pipe and the back-end water baffle have a certain height, so the liquid level can be continuously maintained at the required control height when zero flow occurs. When the liquid level exceeds the height of the baffle, the water flow can quickly flow out over the top of the baffle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com