High-voltage cable conveying machine

A wire feeder and cable technology, which is applied in the direction of conveying filamentous materials, thin material handling, transportation and packaging, can solve problems such as unfavorable cable construction, increased wire wear, and large square numbers, and achieves convenient operation, Guaranteed safety and the effect of reducing cable resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

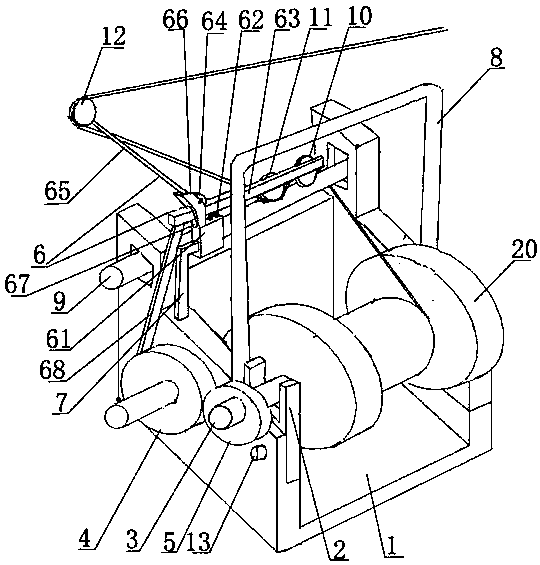

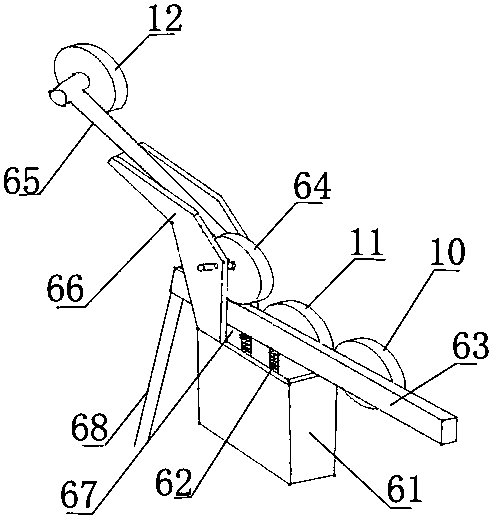

[0026] Such as figure 1 with figure 2 As shown, the cable feeder includes a base 1, a bobbin frame 2, a bobbin 3, a driving gear 4, a driven gear 5, a fixed pulley frame 6, and a fixed pulley block;

[0027] The bobbin frame 2 and the driving gear 4 are respectively installed on the base, and the driven gear 5 is fixedly installed at one end of the bobbin 3, and the bobbin 3 is used to penetrate into the cable winding reel 20 and wind the cable Disc 20 is fixed on the spool 3; said spool 3 is detachably installed on the spool frame 2, when the spool 3 was mounted on the spool frame 2, the driven gear 5 and the driving gear 4 meshed, and the driving gear 4 and the The power mechanism is linked to drive the bobbin 3 to rotate;

[0028] The fixed pulley frame 6 is installed on the base 1 through the fixed rod 7, and is located above the bobbin frame 2. The fixed pulley block is installed on the fixed pulley frame 6, and the cables in the cable winding reel 20 pass through Sen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com