Overlapped spiral type sludge dewatering machine

A sludge dewatering machine and sludge dehydration technology, which is applied in water/sludge/sewage treatment, sludge treatment, dehydration/drying/thickened sludge treatment, etc., can solve low production efficiency, unfavorable sludge incineration treatment, Difficult to deal with centralized treatment of filtrate and sludge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

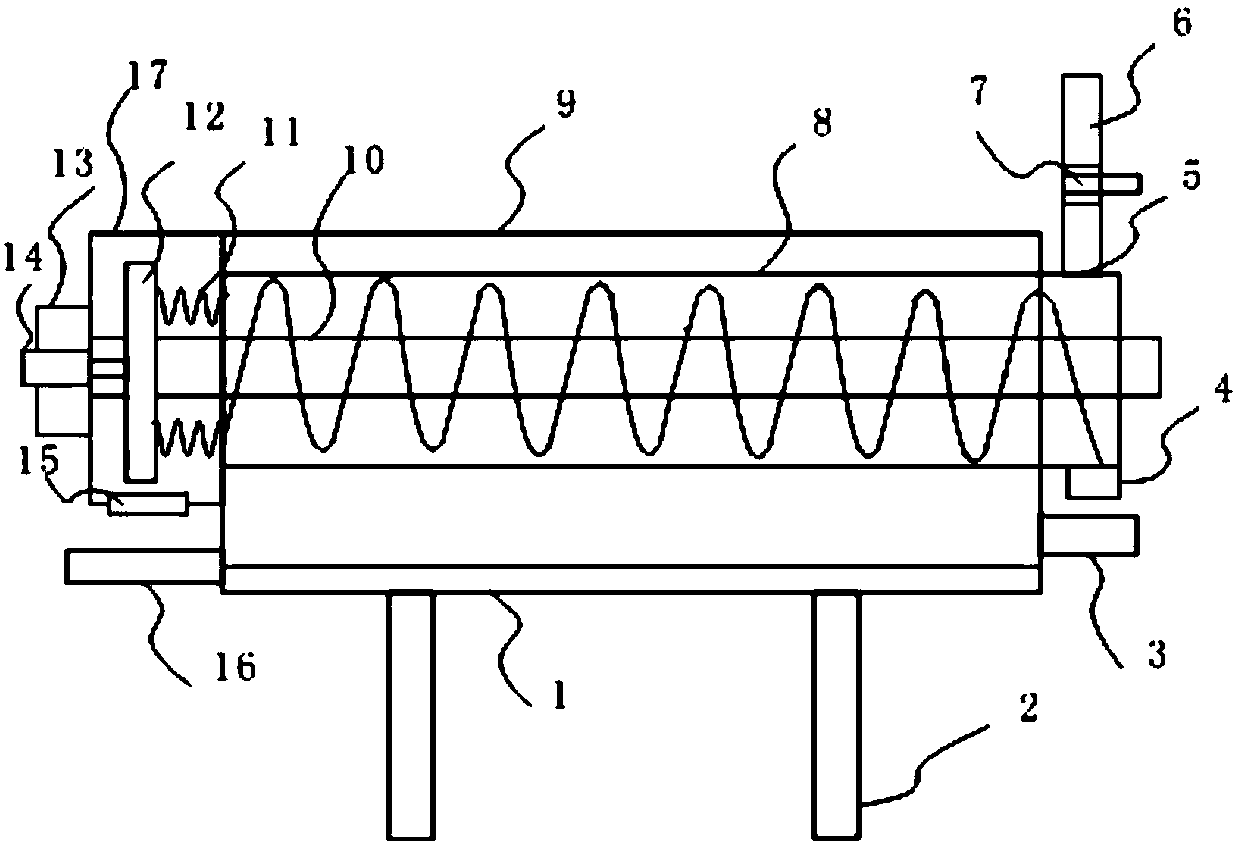

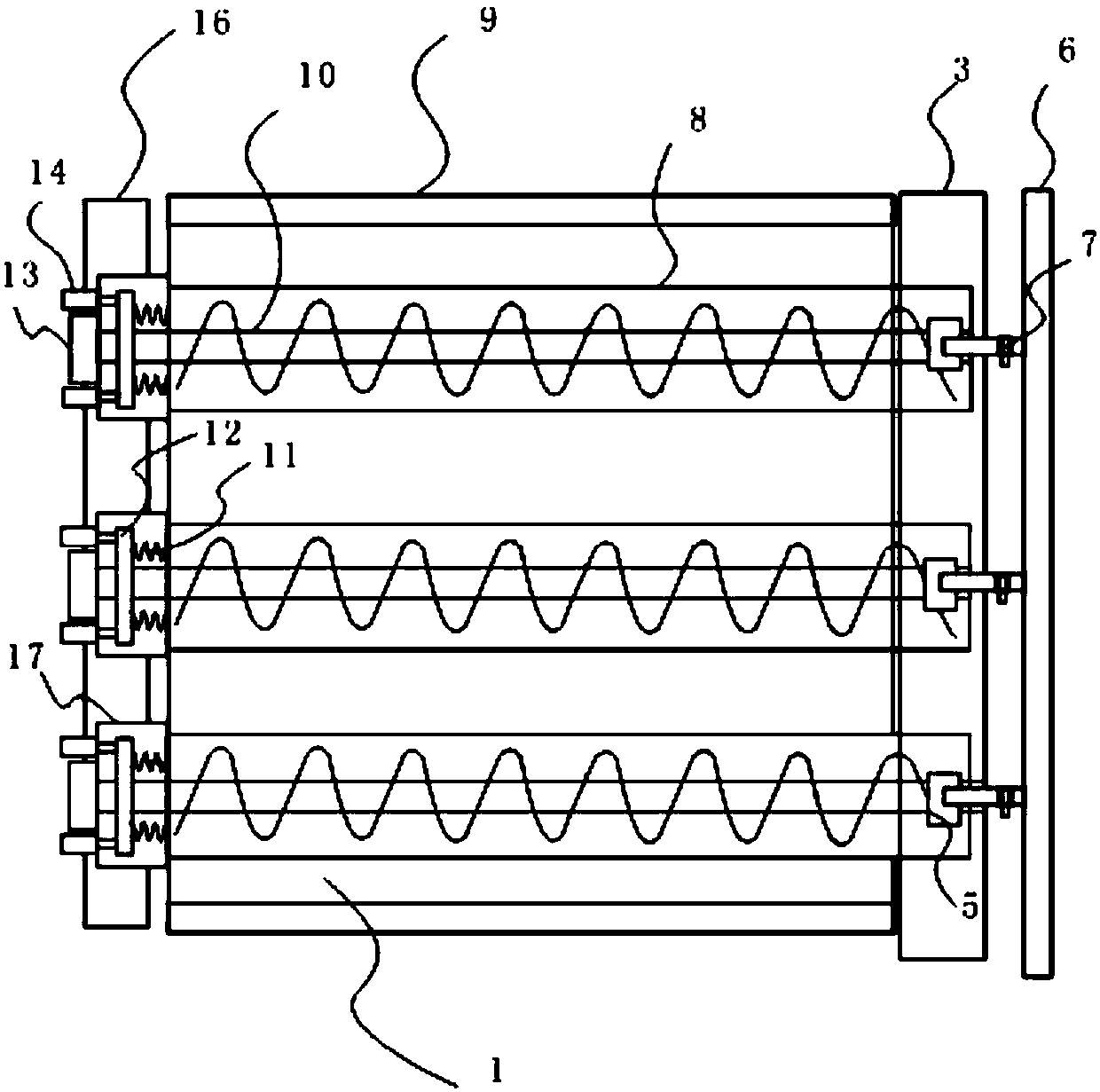

[0017] A screw-stacked sludge dewatering machine, which includes a frame 2 and a screw-stacked sludge dewatering device. The frame includes a bottom plate 1 and baffles 9 hinged to the bottom plate on both sides. The screw-stacked sludge dewatering device is A plurality of them are arranged side by side on the bottom plate, and each stacked screw type sludge dewatering device includes a rotating shaft 10 arranged along the bottom plate and driven by a motor 13, and a screw stacking mechanism 8 sleeved on the shaft to rotate with the shaft, and the downstream end of the stacking screw mechanism There is a feed inlet 5 at the top, and a filtrate outlet 4 at the bottom. Filtrate tanks 3 connected to each other and arranged obliquely are fixedly installed below the filtrate outlets of multiple screw-stacking sludge dewatering devices. The upstream end of the screw-stacking mechanism is provided with A mud discharge chamber 17 connected with the stacking screw mechanism, the mud dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com