Laser cladding preparation method of ceramic reinforced metal base composite coating

A metal matrix composite and laser cladding technology, applied in the field of laser surface engineering, can solve the problems of loss of strengthening effect, unavoidable, aggravated coating cracking tendency, etc., achieve good performance, overcome technical and performance deficiencies

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

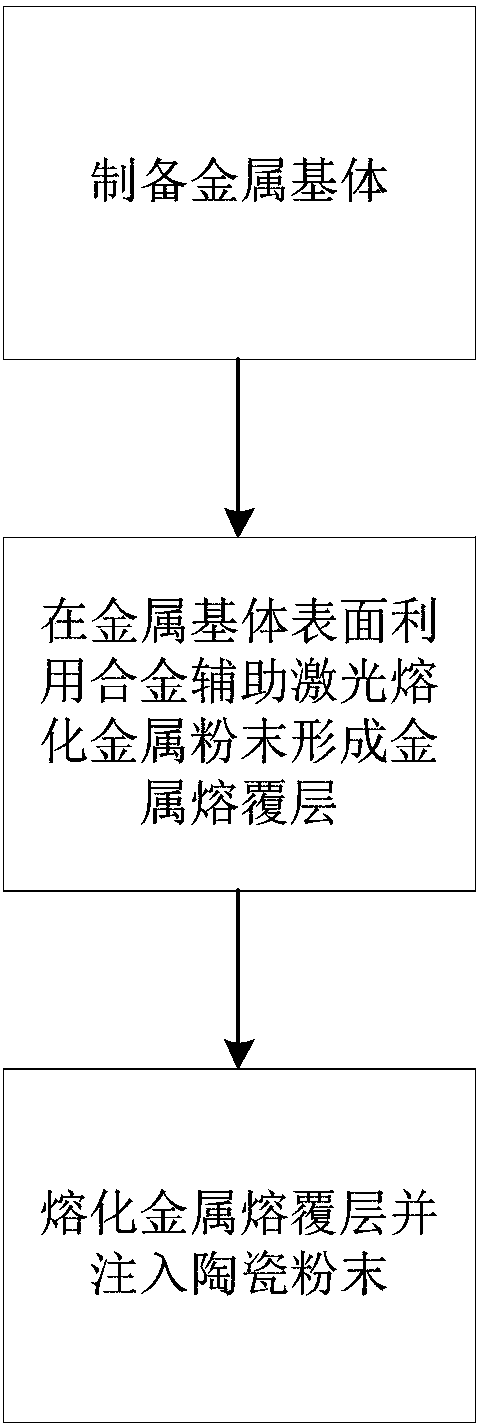

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in conjunction with specific embodiments. The following examples will help those skilled in the art to further understand the present invention, but do not limit the present invention in any form. It should be noted that those skilled in the art can make several changes and improvements without departing from the concept of the present invention. These all belong to the protection scope of the present invention.

[0025] The present invention innovates and improves the conventional laser cladding method. While conventionally forming the metal cladding layer, the cladding layer is heated and melted by adding an auxiliary laser beam to form a molten pool, and then the ceramic powder is simultaneously injected into the melt and solidified. When injecting, the ceramic particles avoid the direct action of the laser beam and enter from the tail of the molten pool. This method avoids the burning and melting of the cerami...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap