Anti-silt rotating water blocking gate

A sluice gate and anti-silting technology, which is applied in water conservancy projects, artificial waterways, buildings, etc., can solve problems such as gate opening and closing, gate deformation and damage, and sediment deposition, etc., to achieve the effect of avoiding gate jamming and reliable use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

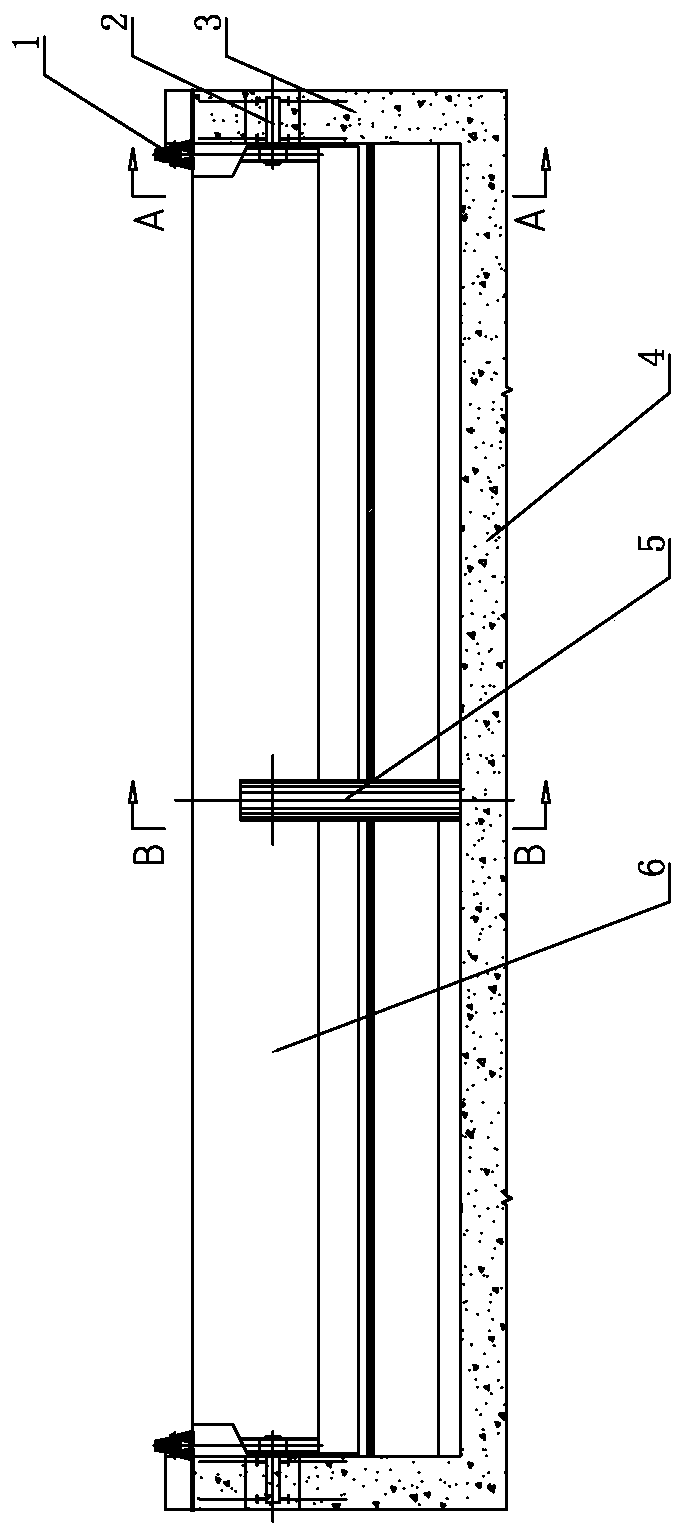

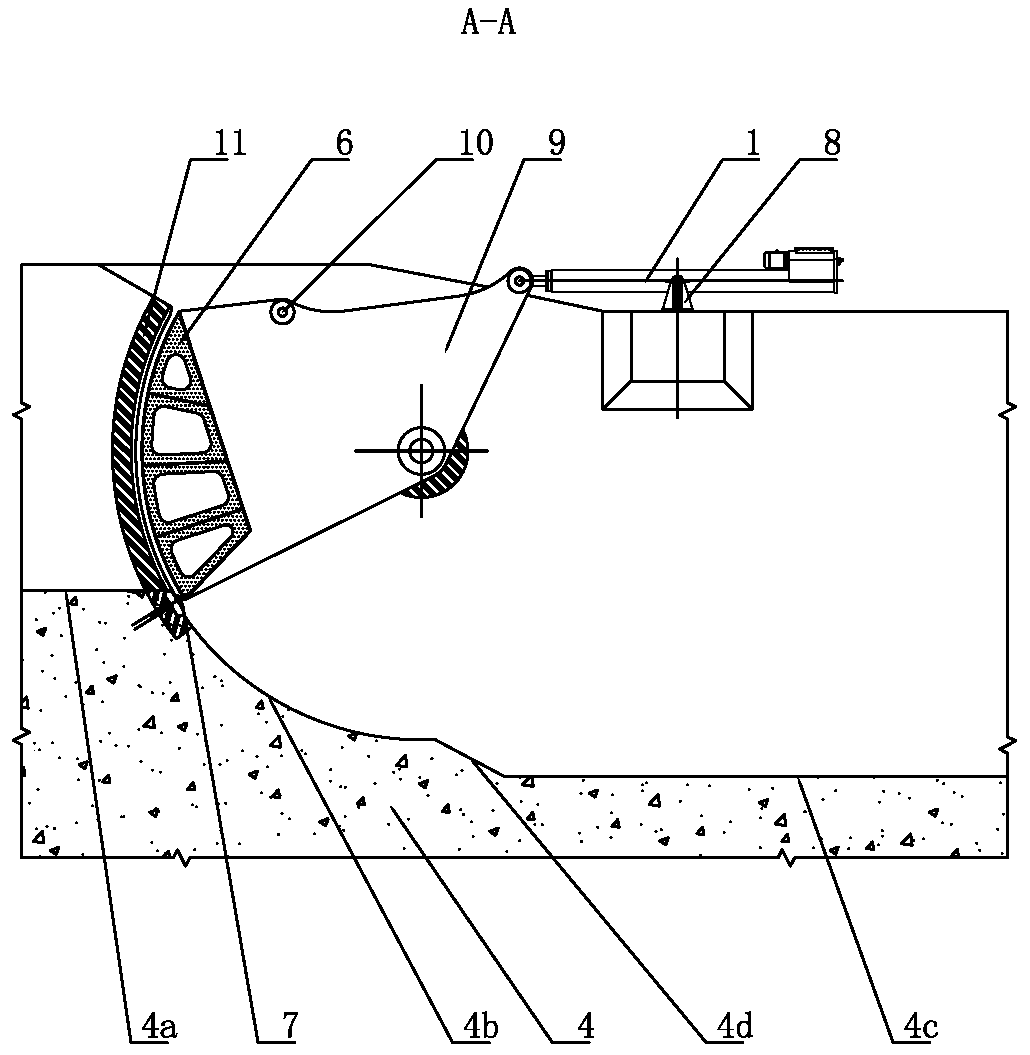

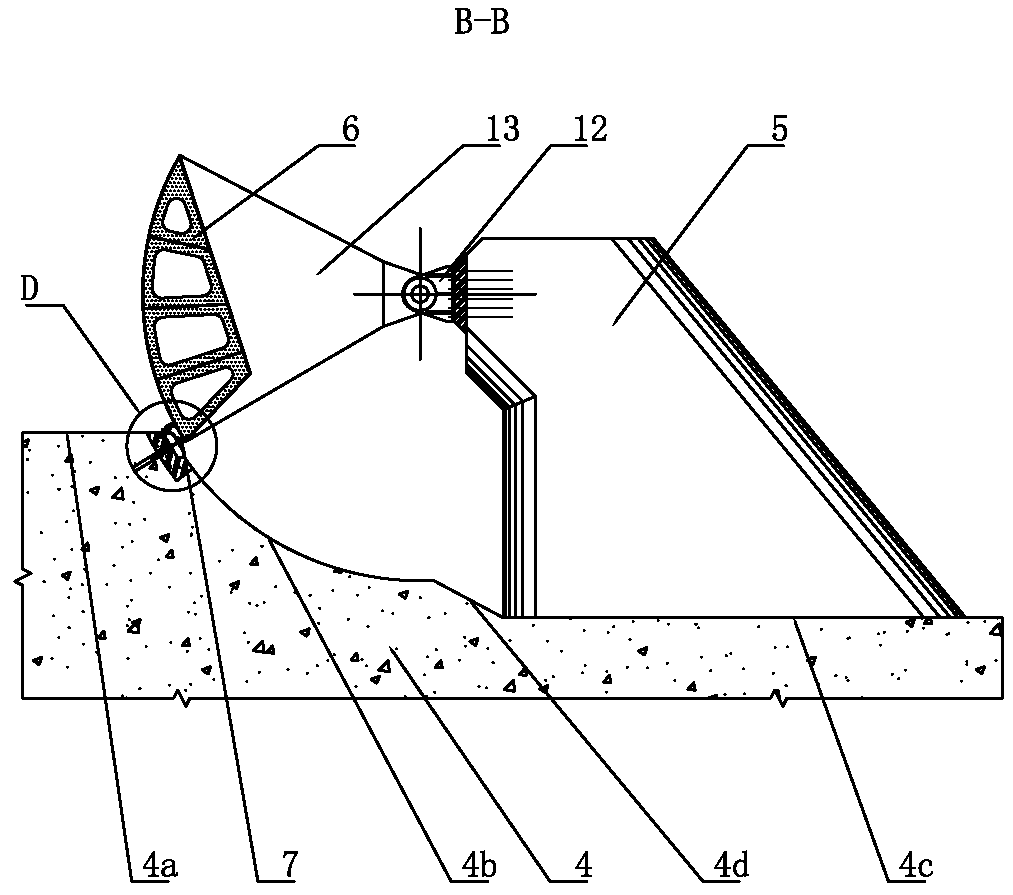

[0020] Such as Figure 1-5 As shown, it is an anti-silting rotary water retaining gate, which includes gate walls 3 arranged on both sides of the river, a floor 4 arranged at the bottom of the river, hoists 1 arranged on both sides of the river, or only on one side of the river. Shutdown; the hoist 1 is hingedly mounted on the hoist base 8, and the river channel is provided with a gate body 6 for blocking water. The arm 9 is rotatably supported on the gate wall 3 via the rotating shaft 2, and the extended end of the piston rod of the hoist 1 is hinged to the rotating arm 9. The bottom plate 4 includes a high-level surface 4a and a low-level surface 4c, and a high-level surface 4a and a low-level surface 4c. There is an arc surface 4b between them, and the arc surface 4b matches the arc surface of the gate body 6. The lowest end of the arc surface 4b is not lower than the plane where the low surface 4c is located. Between the arc surface 4b and the low surface 4c They are conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com