Stirring type corn popper

A popcorn machine and stirring technology, applied in the field of electrical appliances, to achieve the effects of small size, far-reaching use prospects and economic prospects, and prevention of uneven heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

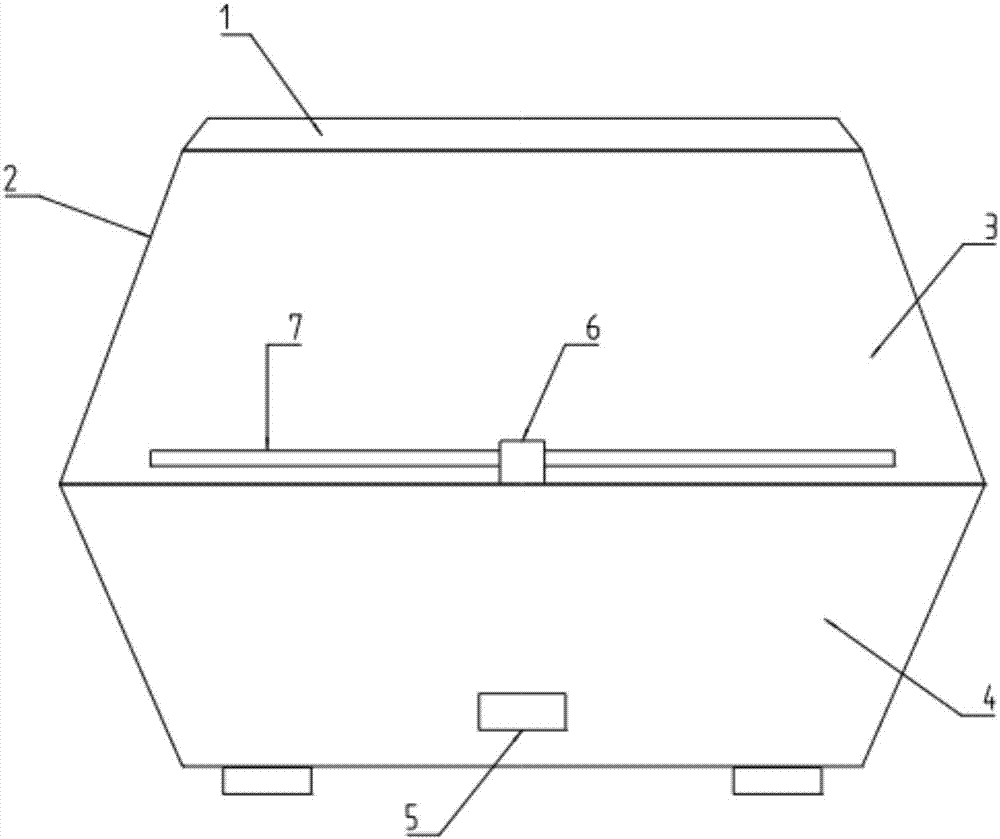

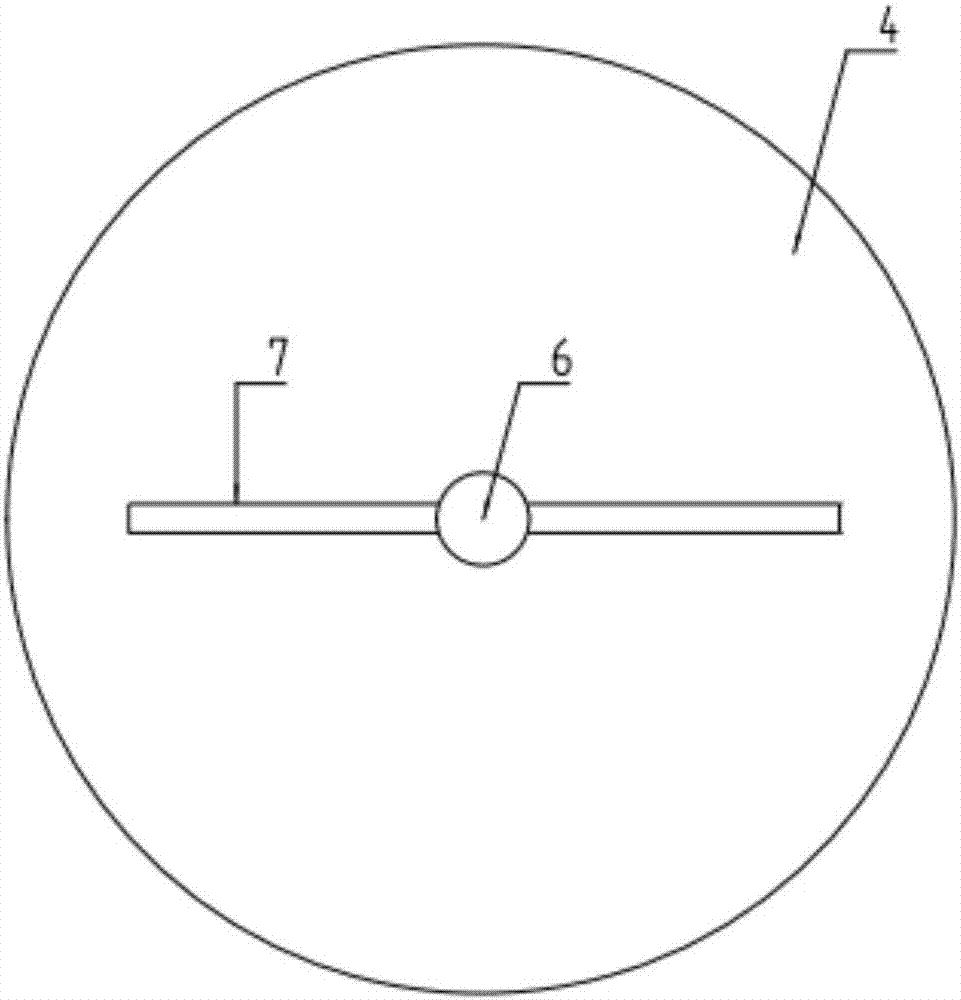

[0014] Such as Figure 1-2 Shown is an embodiment of the stirring popcorn machine according to the present invention.

[0015] The stirring popcorn machine includes an opaque upper cover 11, a transparent upper cover 2, a processing chamber 3, a main body 4, a switch 5, an agitator 6, and a stirring blade 7, wherein the transparent upper cover 2 is removably arranged on the main body 4, The opaque upper cover 1 is fixedly mounted on the top of the transparent upper cover 2 to provide a heat-insulated grip, the space between the transparent upper cover 2 and the main body 4 constitutes a processing chamber 3, and the upper surface of the main body 4 is provided with a heating surface for stirring The device 6 protrudes from the center of the heating surface of the main body 4 , the stirring blade 7 is arranged on the agitator 6 , and is used for stirring the popcorn being heated, and the switch 5 is arranged on the main body 4 .

[0016] Preferably, a controller and a communic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com