Degradable express bag material

A technology of lauric acid polyoxyethylene and high-density polyethylene, applied in the field of express bags, can solve problems such as white pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The preparation method of above-mentioned degradable courier bag material comprises the following steps:

[0031] At room temperature, put high-density polyethylene, starch, polyethylene-grafted maleic anhydride, polylactic acid, polyoxyethylene laurate, and coupling agent into a mixer and stir evenly, then add additives, and continue stirring until the mixture is uniform. The mixture is obtained, and finally the mixture is extruded and granulated on a twin-screw extruder, and the granulation is the degradable express bag material.

[0032] When the above-mentioned degradable express bag material is used to prepare the express bag, the degradable express bag material is melt-extruded and blow-molded into the express bag.

[0033] The degradable express bag material of the present invention uses high-density polyethylene as the base material, high-density polyethylene, starch, polyethylene grafted with maleic anhydride, polylactic acid, polyoxyethylene laurate and a coup...

Embodiment 1

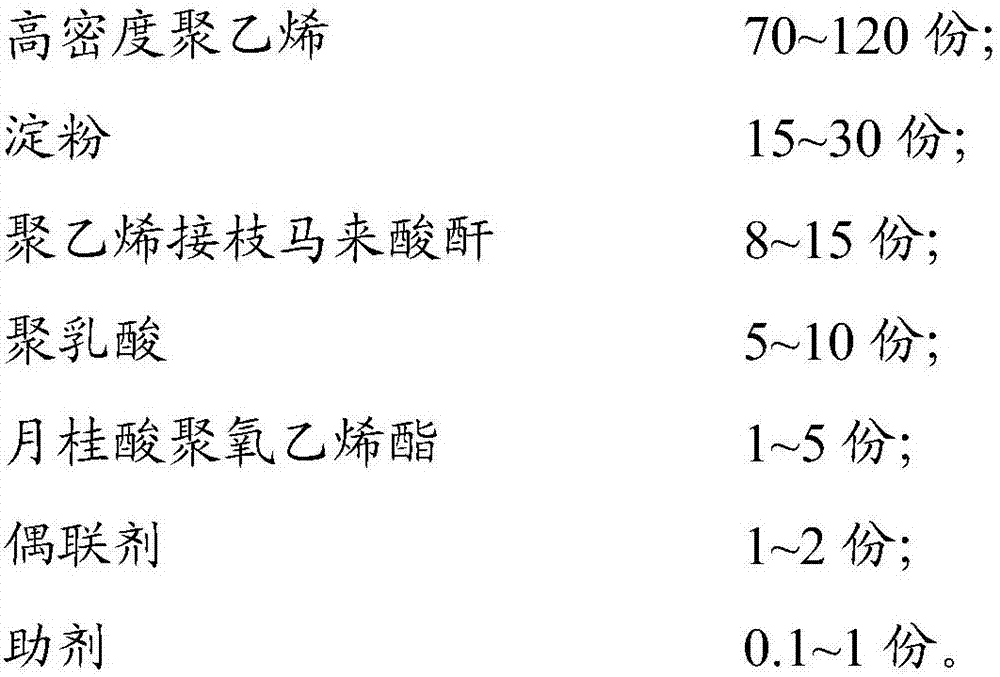

[0037] The degradable express bag material of the present embodiment comprises the following components by weight:

[0038]

[0039] The molecular weight range of high-density polyethylene is selected from 60,000 to 100,000, and its melt flow rate is 15 to 20g / 10min.

[0040] The graft ratio of polyethylene grafted with maleic anhydride is 1%, and the melt flow rate is 7-10g / 10min.

[0041] Polylactic acid is a mixture of poly-L-lactic acid and poly-racemic lactic acid, and the mass ratio of poly-L-lactic acid and poly-racemic lactic acid is 4:1.

[0042] Polyoxyethylene laurate is selected from the mixture of polyoxyethylene-2 laurate and polyoxyethylene-9 laurate, and the mass ratio of polyoxyethylene-2 laurate to polyoxyethylene-9 laurate is 1: 1.

[0043] The coupling agent is ethoxysilane.

[0044] The auxiliary agents are antioxidant BHT and white masterbatch, wherein the antioxidant BHT is 0.1 part by weight, and the white masterbatch is 0.2 part by weight.

...

Embodiment 2

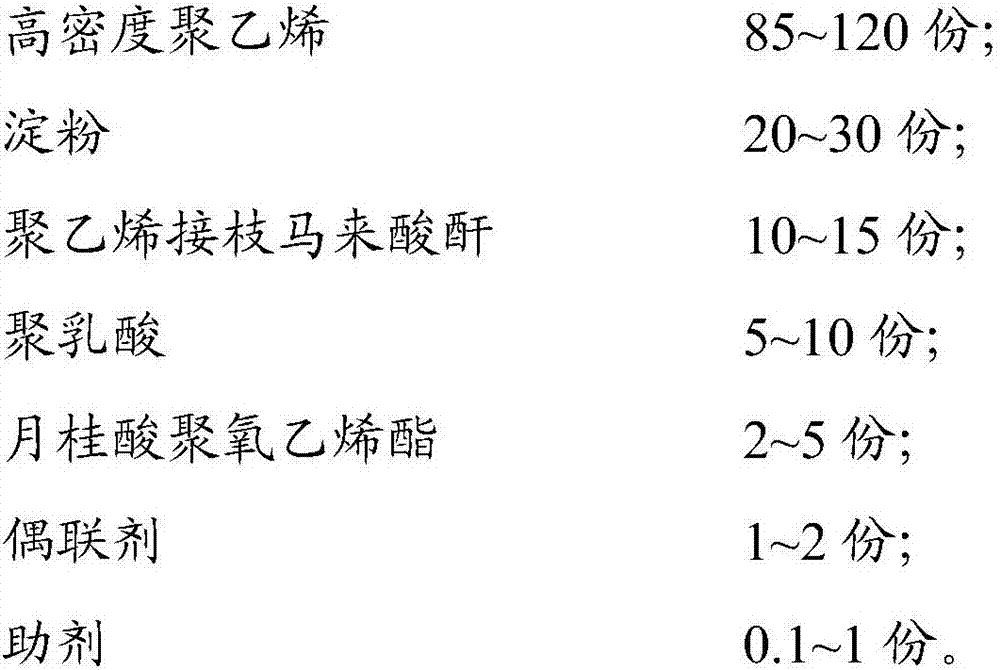

[0048] The degradable express bag material of the present embodiment comprises the following components by weight:

[0049]

[0050] The molecular weight range of high-density polyethylene is selected from 80,000 to 150,000, and its melt flow rate is 12 to 15g / 10min.

[0051] The graft ratio of polyethylene grafted with maleic anhydride is 1.2%, and the melt flow rate is 6-8g / 10min.

[0052] Polylactic acid is a mixture of poly-L-lactic acid and poly-racemic lactic acid, and the mass ratio of poly-L-lactic acid and poly-racemic lactic acid is 5:1.

[0053] Polyoxyethylene laurate is polyoxyethylene-4 laurate.

[0054] The coupling agent is a mixture of acetoxysilane and chlorosilane, and the mass ratio of acetoxysilane to chlorosilane is 2:1.

[0055] The additive is antioxidant T501.

[0056] The preparation method and application of the above-mentioned degradable express bag material include the following steps:

[0057] At room temperature, by weight, 85 parts of high-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com