Wind power tower tube

A technology for wind power towers and towers, which is applied to wind power generation, installation/support of wind turbine configurations, etc., can solve the problems of insufficient support of the support structure, improve stability and anti-vibration ability, and is simple to manufacture and assemble. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

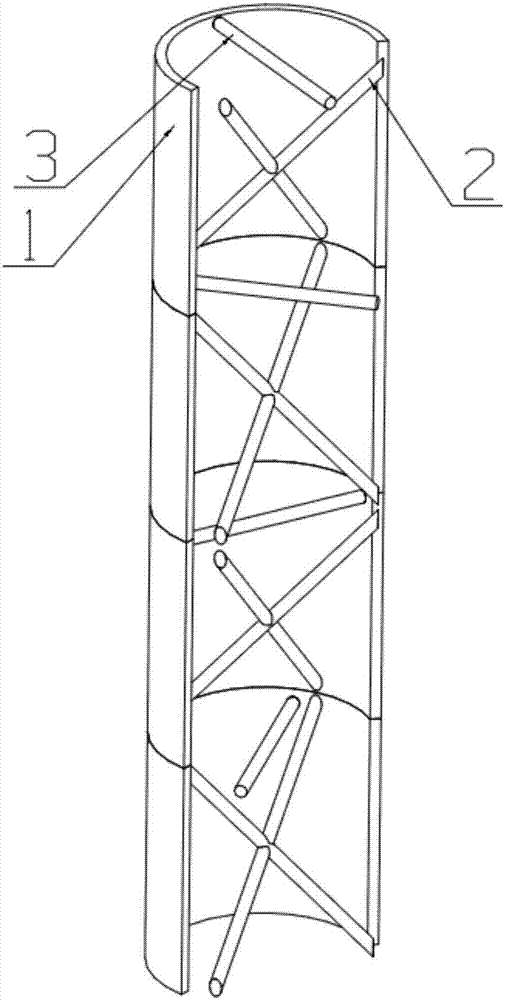

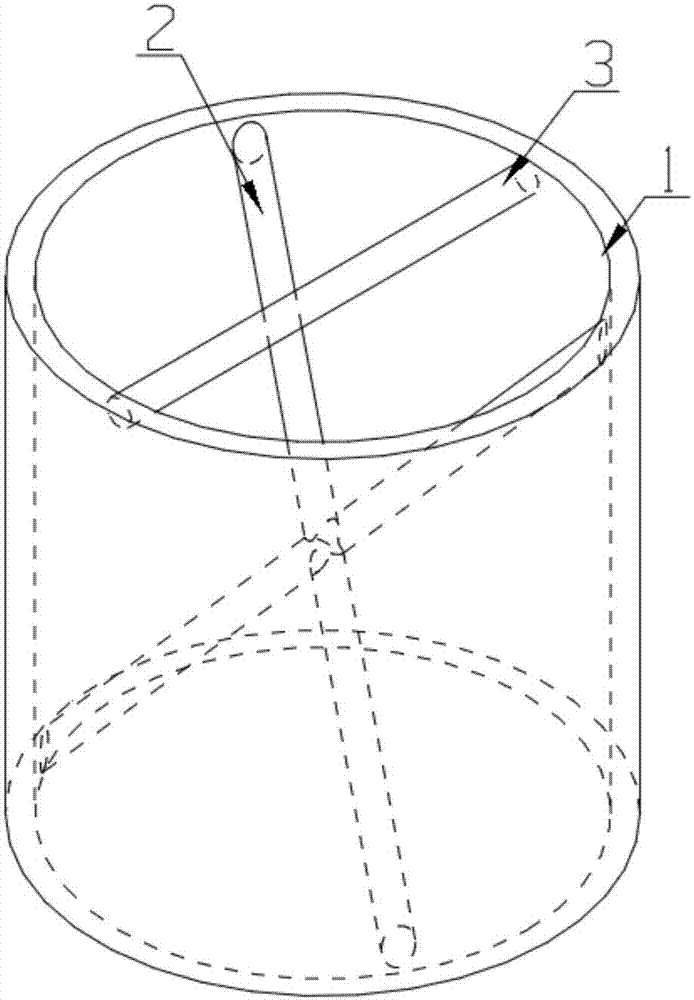

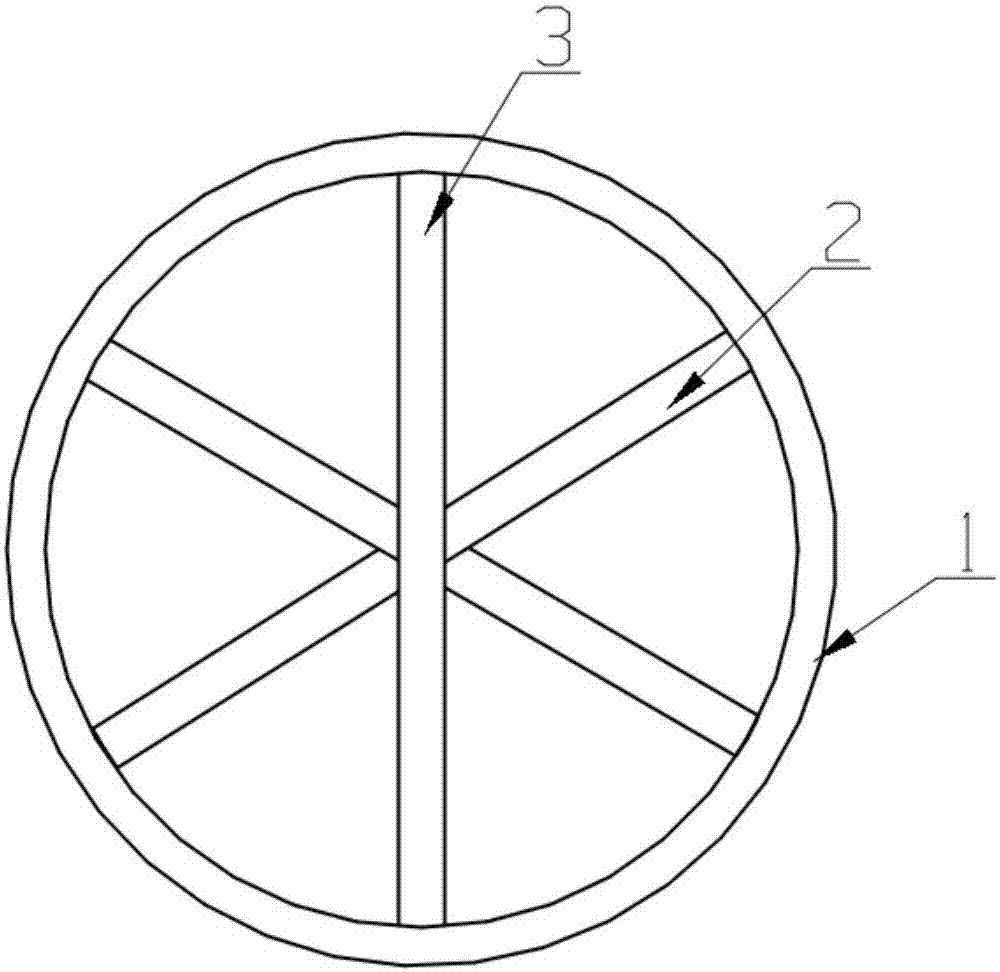

[0043] This embodiment provides a wind power tower, including a tower shell 1 and a support unit, the tower shell 1 is cylindrical; the support unit has multiple groups, and the tower shell 1 The axial direction is distributed inside the tower shell 1 and connected with the inner wall of the tower shell 1; the support unit includes several support members; the support members pass through the tower shell 1 axis The cores are connected to the inner walls of the opposite sides of the tower shell 1 . The support member thus arranged can support the inner walls of the tower shell 1 on opposite sides in the radial direction, so that when the vertical tower shell 1 swings, the inner wall of the tower shell 1 will have The trend from circular to elliptical, at this time, the supporting member extending from one side of the inner wall of the tower shell 1 to the other side of the inner wall will support the inner wall of the tower shell 1 well, effectively improving the tower The sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com