Safe screw pump

A kind of screw pump, safe technology, applied in the direction of pump, pump components, rotary piston pump, etc., can solve the problems affecting the matching accuracy and performance of each component, unable to transport flammable materials, pump temperature rise, etc., to ensure cooperation Accuracy and performance, conducive to safe and stable operation, and the effect of reducing operating temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

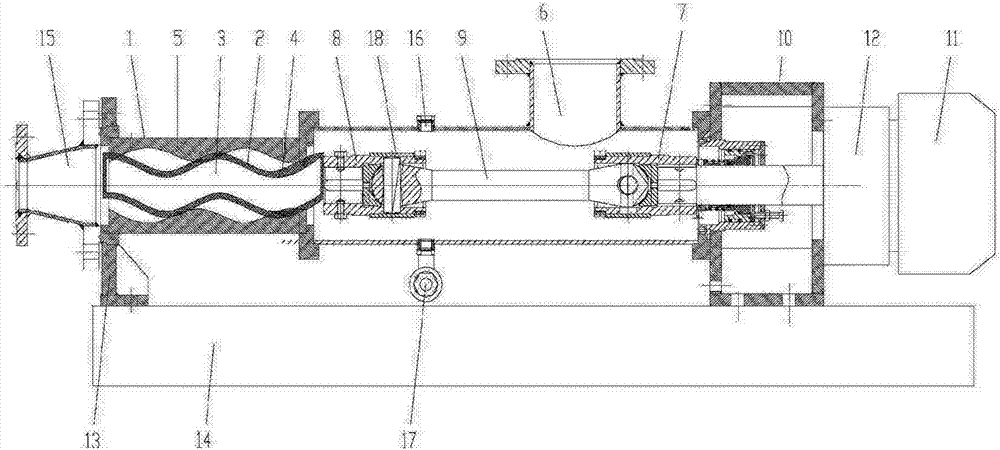

[0011] figure 1 It is a schematic structural diagram of the present invention, as shown in the figure: the safety screw pump of this embodiment includes a pump body 1; the rotor 2 of the pump body 1 includes a skeleton 3 and a non-metallic layer 4 coated and fixed on the outside of the skeleton 3; The skeleton 3 and the stator 5 of the pump body 1 are all made of metal materials; the stator 5 has good thermal conductivity, which is beneficial to heat dissipation, can reduce the working temperature of the pump body 1, ensures the matching accuracy and performance of each component, and prolongs the service life; The outer circular surface of the stator 5 is provided with annular fins arranged along the circumferential direction, and the annular fins are multiple and uniformly arranged along the axial direction of the stator 5. The heat dissipation plate and the annular fins are intersected and fixed into a net shape, and the annular fins and the longitudinal heat dissipation pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com