Integrated automatic lead inserting device for compression molded combined firework

An integrated, potted flower technology, which is applied in pyrotechnics, offensive equipment, weapon types, etc., can solve the problems of difficult potted flower molded body transmission channels, inability to realize direct conveying by conveyor belts, low insertion processing efficiency, etc., and achieve coordinated actions and small size , reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

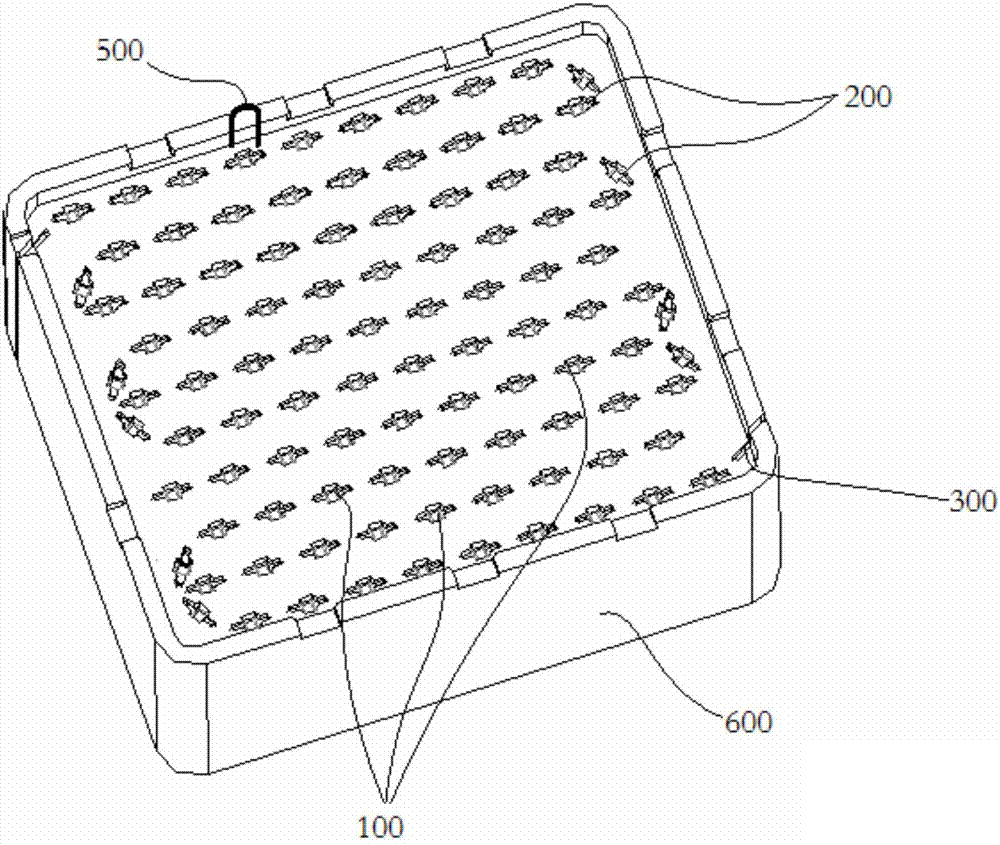

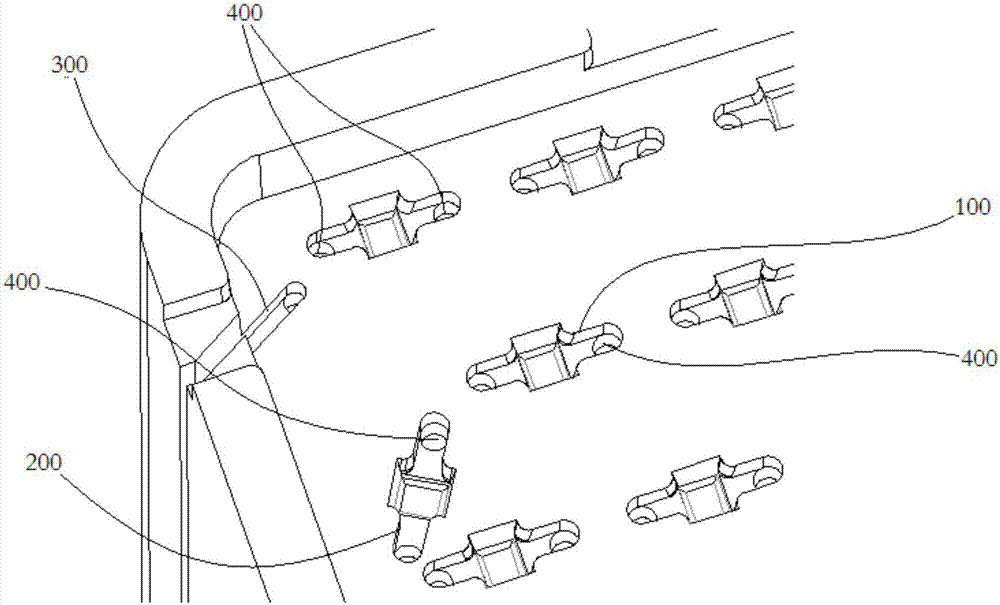

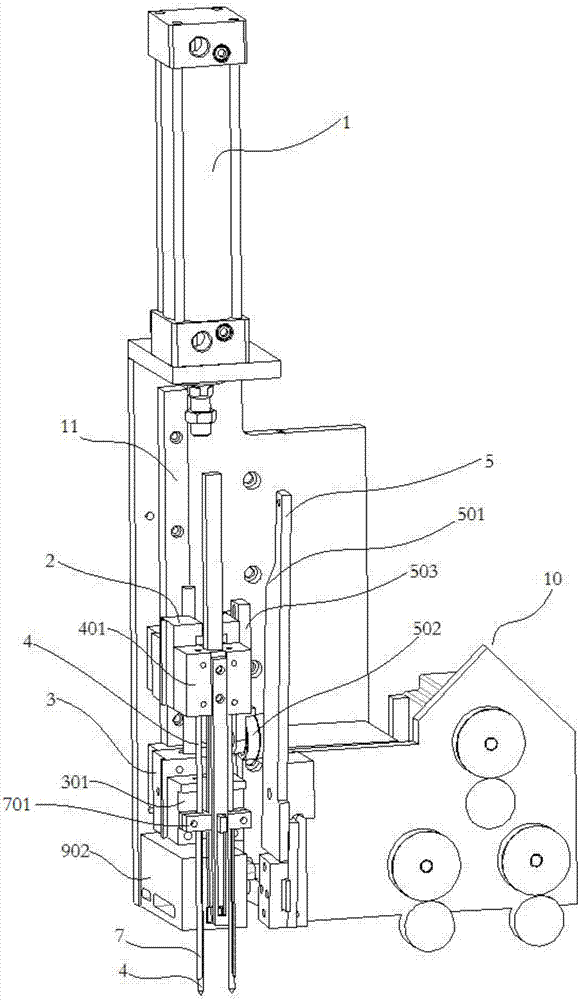

[0036]Referring to the accompanying drawings, which reflect a specific structure of the present invention, the integrated automatic insertion device for molded potted flowers includes a lead wire delivery mechanism 10 composed of clamping and feeding pulley sets and a driving cylinder 1 for punching and insertion. It also includes an upper slider 2 and a lower slider 3 arranged on the upper and lower guide rails 11, and the upper slider 2 is fixedly connected to the push head of the driving cylinder 1. The elastic connection structure between the upper slider 2 and the lower slider 3 is: the lower slider 3 is fixed to the lower end of the orientation shaft 302, and the upper end of the orientation shaft 302 passes through the guide hole of the upper slider 2 and hangs on the upper slider 2 On the orientation shaft 302 between the upper slider 2 and the lower slider 3, the spring A (not shown in the figure) is set to form an elastic connection: the downward movement of the lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com