Flexible display panel, flexible display device and manufacturing method thereof

A flexible display and flexible substrate technology, applied in chemical instruments and methods, final product manufacturing, other household appliances, etc., can solve the problems of easy wear and tear of electronic components, abnormal screen display, low bending resistance, etc., to reduce the screen. Probability of abnormal display, reduction of stress change, effect of reducing wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0054] In the method for preparing a flexible display panel provided in this embodiment, two flexible buffer regions with different bending strengths are formed on the base substrate. In the display device, electronic components with low bending resistance are formed at the bending strength In the lower flexible buffer zone, the stress on the area with weaker bending strength will be dispersed to the area with stronger bending strength, which is beneficial to reduce the stress change in the area with poor stress during bending deformation and reduce wear.

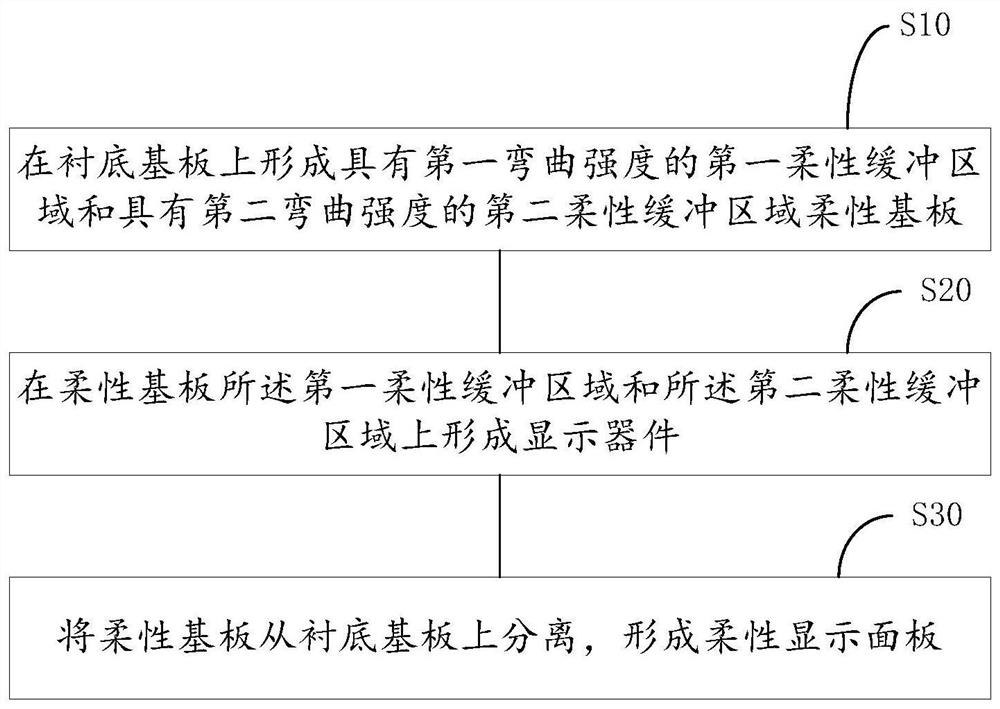

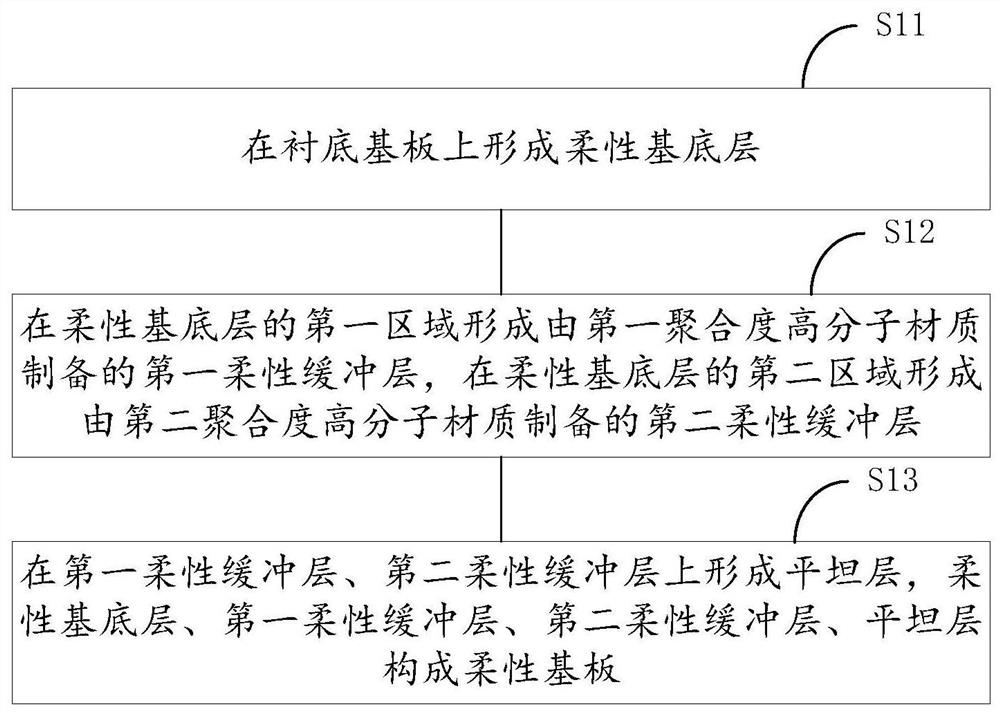

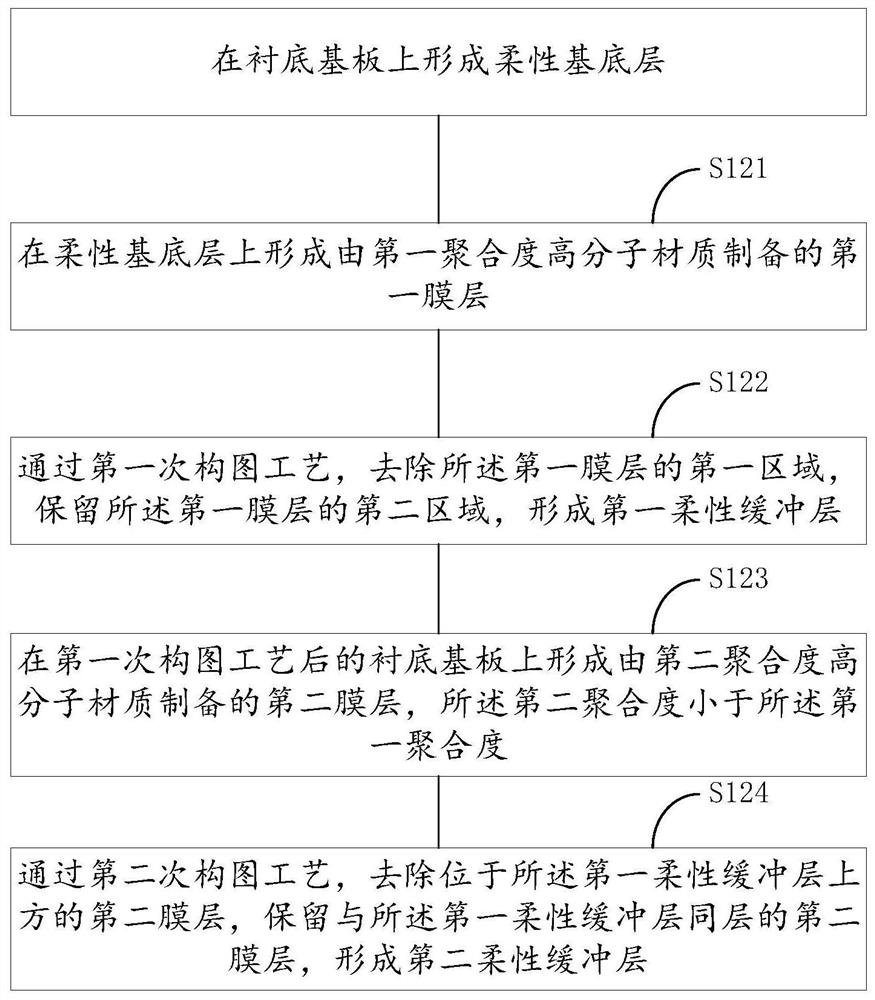

[0055] Figure 1 to Figure 2 For an embodiment of the preparation method of the flexible display panel provided by the present invention, please refer to Figure 1 to Figure 2 , a method for preparing a flexible display panel proposed by an embodiment of the present invention, including:

[0056] S10, forming a flexible substrate with a first flexible buffer region having a first bending strength and a second flexible buff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com