Tubular bus-bar corner support over-current fitting for flexible DC transmission engineering converter stations

A flexible DC power transmission and converter station technology, which is used in electrical components, busbar installation, cable installation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

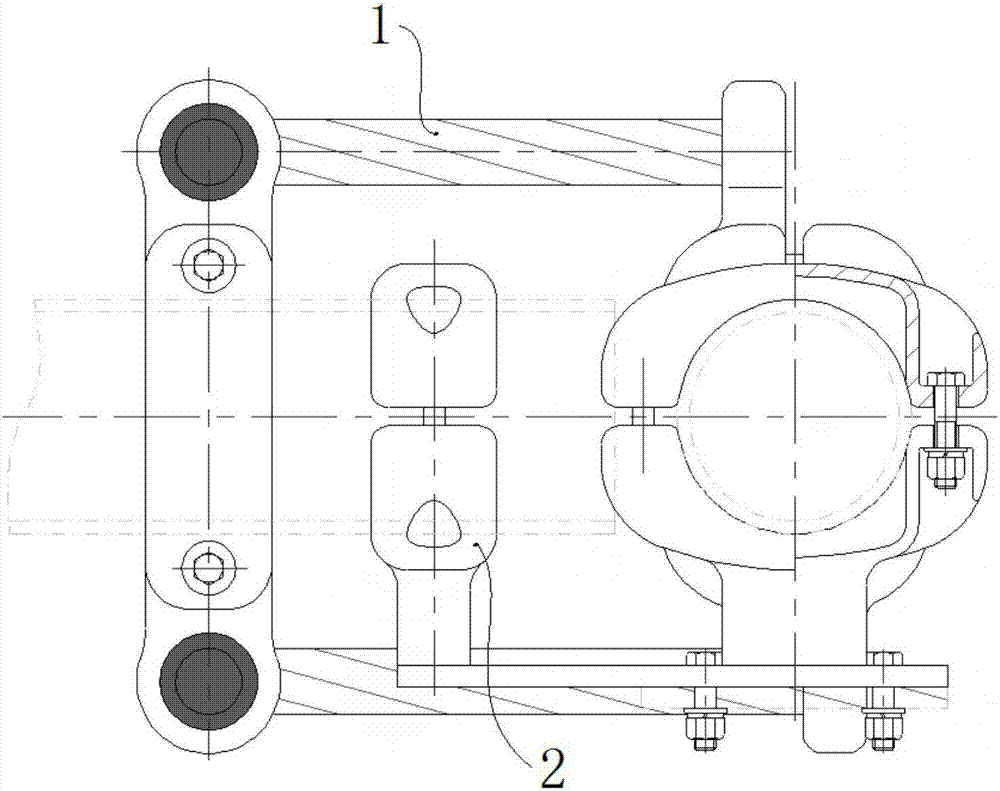

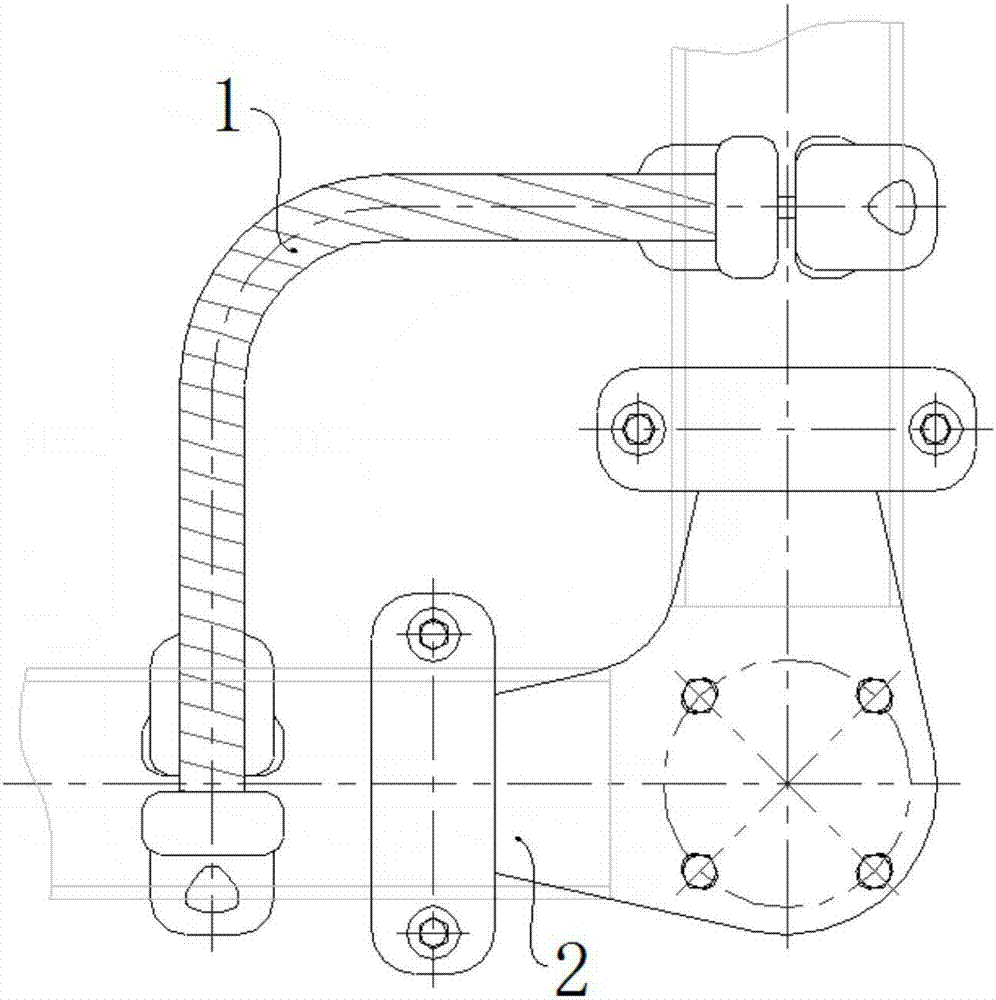

[0016] Such as figure 1 , figure 2 As shown, the present invention proposes a pipe nut corner support overcurrent fitting for a converter station of a flexible direct current transmission project, which includes an overcurrent fitting assembly 1 and a pipe nut corner support assembly 2 .

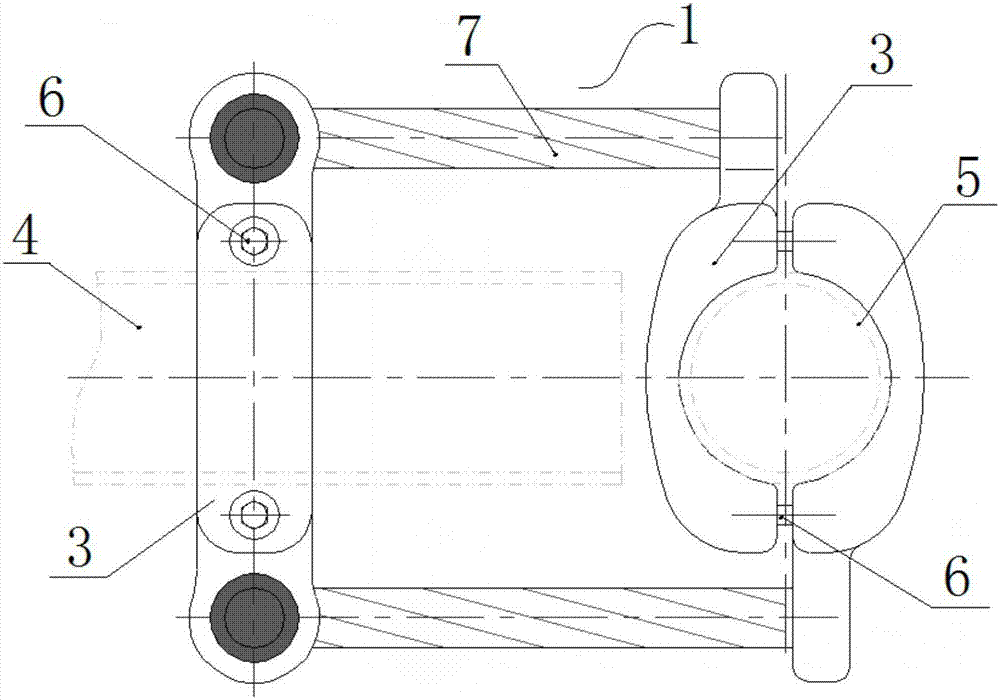

[0017] Such as image 3 , Figure 4 As shown, the overcurrent fitting assembly 1 includes two pipe female overcurrent fitting bodies 3, and the two pipe female overcurrent fitting bodies 3 are respectively sleeved on the pipe busbar 4 and the pipe busbar 5 which are in a perpendicular relationship with each other and are tightened by fastening bolts. 6. Install and fix. Two pure aluminum stranded wires 7 are connected between the two tube busbars 4 and 5. All parts are welded with the pipe mother overcurrent fitting body 3.

[0018] Such as Figure 5 , Fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com