Motor drive device, drive device of compressor using the same, and refrigerator

一种驱动装置、电动机的技术,应用在冷藏库领域,能够解决不能应对稳定性、提高等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

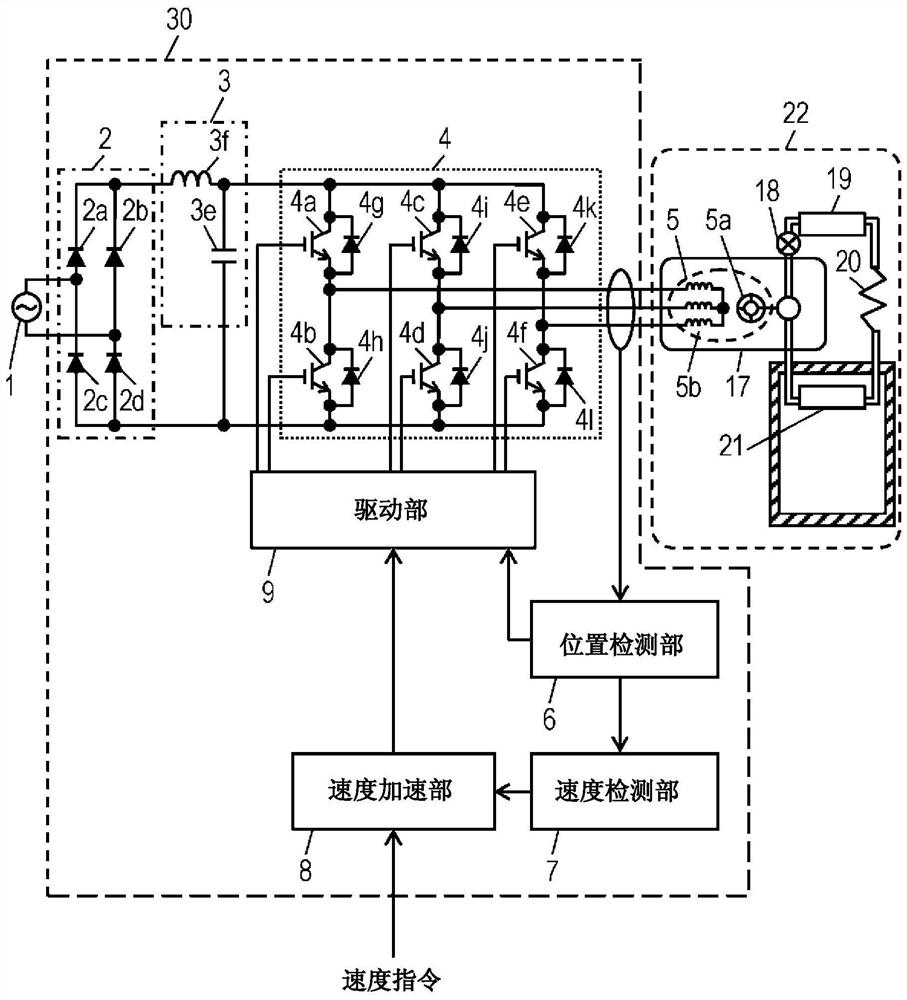

[0077] figure 1 It is a block diagram of the motor drive device according to Embodiment 1 of the present invention.

[0078] figure 1 Among them, the motor driving device 30 is connected to the AC power source 1 to drive the brushless DC motor 5 . The AC power supply 1 is a common industrial frequency power supply, which is a 50Hz or 60Hz power supply with an effective value of 100V in Japan. Hereinafter, the configuration of the motor drive device 30 will be described.

[0079] The rectification circuit 2 receives the AC power supply 1 as an input and rectifies AC power into DC power, and is composed of four bridge-connected rectifier diodes 2a to 2d.

[0080] The smoothing unit 3 is connected to the output side of the rectification circuit 2 and smoothes the output of the rectification circuit 2 . The smoothing unit 3 is composed of a smoothing capacitor 3e and a reactor 3f. The output from smoothing unit 3 is input to inverter 4 .

[0081] In addition, since the rea...

Embodiment approach 2

[0149] The motor drive device 82 according to Embodiment 2 of the present invention will be described. Figure 7 It is a block diagram of a motor drive device according to Embodiment 2 of the present invention. Figure 2, pair with figure 1 The same configurations as those shown in Embodiment 1 are denoted by the same symbols, and description thereof will be omitted.

[0150] In the present embodiment, the configurations of the rectifier circuit 2, the smoothing unit 3, and the inverter 4 constituting the motor drive device 82, and the brushless DC motor 5 constituting the refrigerator 22 are the same as those in the first embodiment.

[0151] In addition, the structure of the position detection part 76 of the motor drive device 82 of this embodiment is the same as that of the position detection part 6 of Embodiment 1. As shown in FIG.

[0152] The speed detection unit 77 calculates the current drive speed of the brushless DC motor 5 and the average speed of one revolution i...

Embodiment approach 3

[0211] Figure 12 A block diagram showing the motor drive device 120 according to Embodiment 3 of the present invention.

[0212] Figure 12 Among them, the power supply 121 is an ordinary commercial frequency power supply, and in the case of Japan, it is a 50Hz or 60Hz AC power supply with an effective value of 100V. The rectifying and smoothing circuit 122 is composed of a rectifying unit 122a and a smoothing unit 122b, receives the AC power supply 121 as an input, and converts the AC voltage into a DC voltage. The rectification and smoothing circuit 122 in this embodiment adopts a voltage doubler rectification structure, but it can also be a full-wave rectification structure, or can be set as a structure switching between full-wave rectification and voltage doubler rectification, or can be a power factor improvement circuit (PFC), etc. .

[0213] In the inverter 123, six switching elements 123a to 123f are connected in a three-phase full-bridge structure, converts the DC i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com