Hand-lifting type fire-fighting monitor

A fire monitor, hand-carried technology, applied in the field of hand-carried fire monitors, can solve the problems of easy displacement, high production cost, long processing time, etc., to achieve convenient transportation and loading and unloading, low processing cost, easy operation and maintenance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

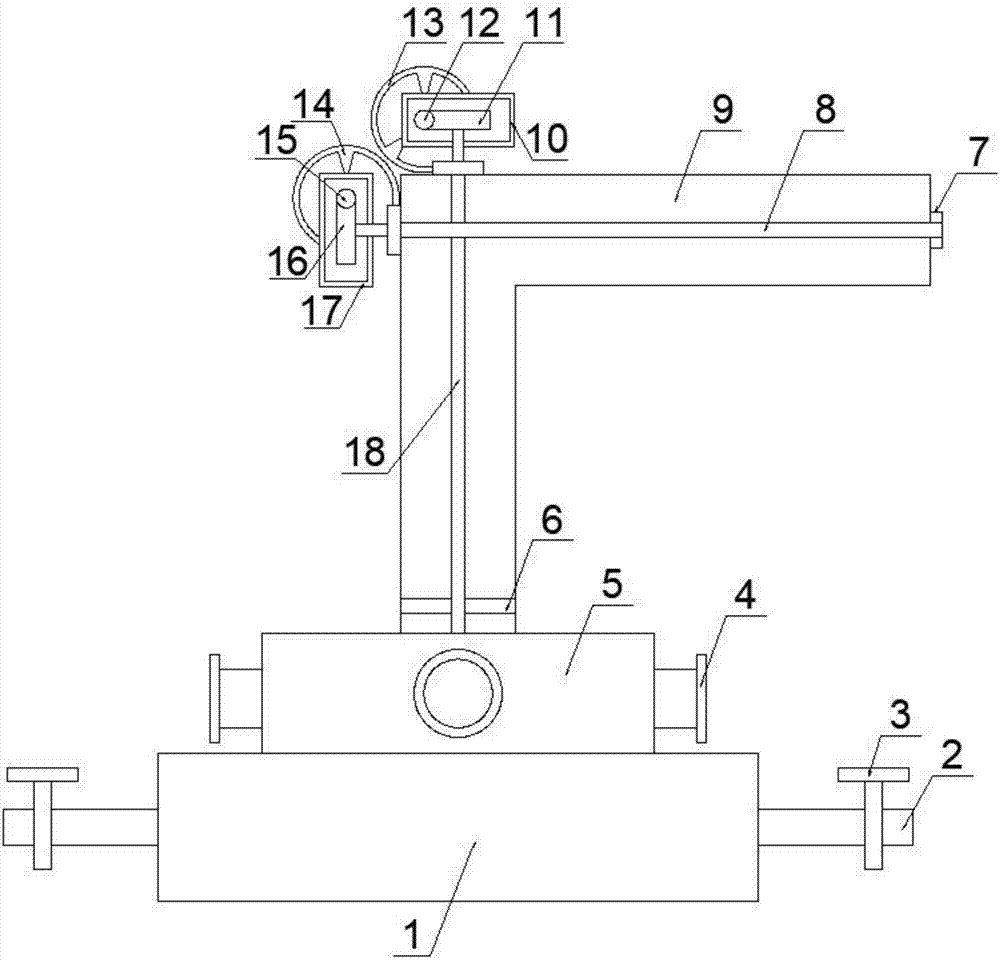

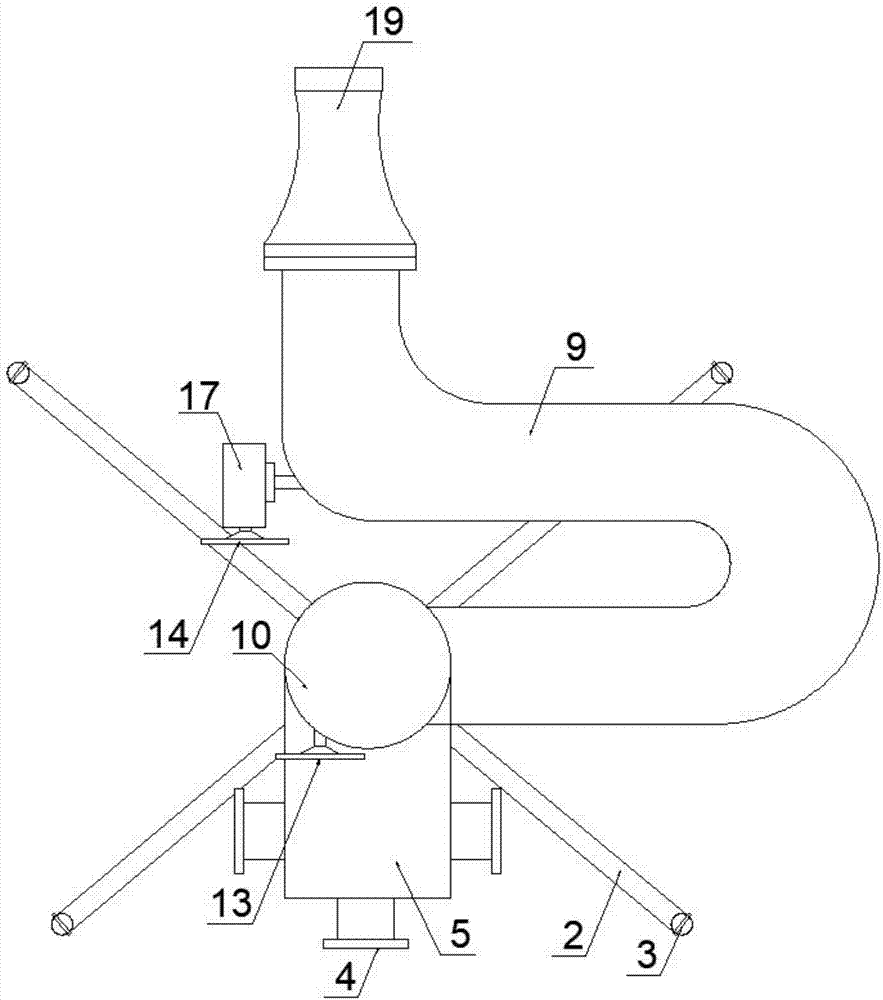

[0013] Embodiment 1, see figure 1 , figure 2 , a hand-carried fire monitor, comprising: a mounting base 1, a bracket fixing rod 2, a bracket fixing bolt 3, a water inlet port 4, a water collection tank 5, a vertical transmission shaft fixing key 6, a horizontal transmission shaft fixing key 7, a horizontal transmission Shaft 8, water outlet pipe 9, horizontal reducer 10, horizontal fixed wheel 11, horizontal rotating wheel 12, horizontal handwheel 13, vertical handwheel 14, vertical rotating wheel 15, vertical fixed wheel 16, vertical reducer 17, vertical transmission shaft 18. Water outlet 19; wherein: the top of the installation base 1 is fixedly connected to the bottom of the water collection tank 5, and the outer wall around the water collection tank 5 is fixedly provided with a water inlet port 4, and the outer walls on both sides of the installation base 1 are fixedly connected to one end of the bracket fixing rod 2, and the bracket is fixed The other end of the rod 2 ...

Embodiment 2

[0014] Example 2, see figure 1 , figure 2 , a hand-carrying fire monitor, wherein: the bracket fixing rod 2, the bracket fixing bolt 3, and the number of water inlet ports 4 are all four, so as to ensure that the device can be fixed firmly when in use, and at the same time, the water intake can be guaranteed according to actual use requirements. All the other are with embodiment 1.

Embodiment 3

[0015] Example 3, see figure 1 , a hand-carrying fire monitor, wherein: the horizontal hand wheel 13, the vertical hand wheel 14 are provided with anti-skid grooves, easy to operate, to prevent slipping. All the other are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com