Fireproof flame-retardant corrugated board

A technology for flame retardant corrugated cardboard and corrugated paper, applied in the field of corrugated cardboard, can solve the problems of difficult control of the amount of sprayed fire retardant, inability to achieve fire retardant effect, complicated processing technology, etc., so as to improve the fire retardant effect and fire resistance The effect of good combustion effect and simplified production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

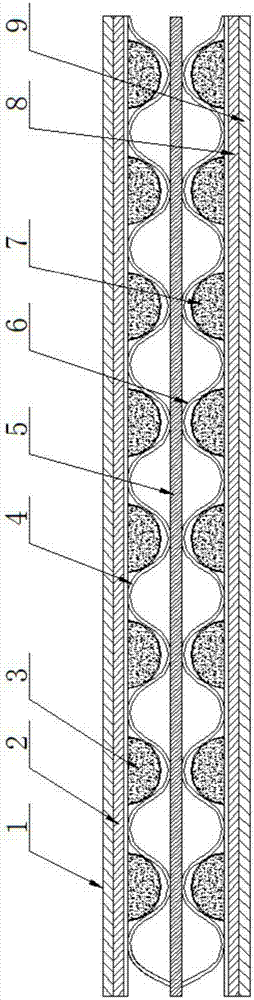

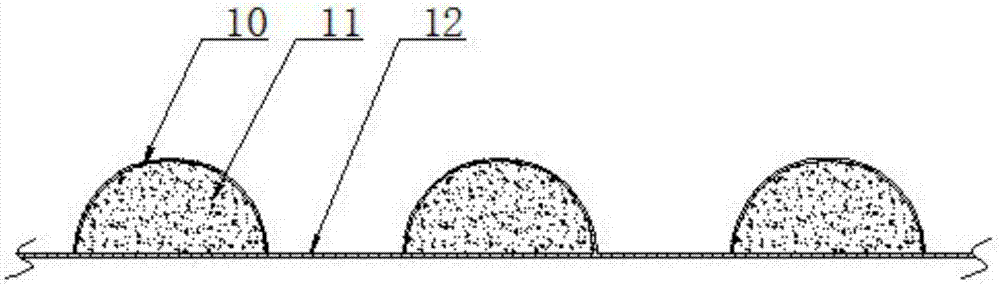

[0019] A fire-proof and flame-retardant corrugated cardboard, comprising an upper layer of paper 1, an upper layer of corrugated paper 4, a core paper 5, a lower layer of corrugated paper 6 and a lower layer of paper 9 stacked sequentially from top to bottom, and an upper layer of corrugated paper is arranged between the upper layer of corrugated paper and the upper layer of paper. The flame-retardant bubble layer 3, the lower air-retardant flame-retardant layer 7 is arranged between the lower layer of corrugated paper and the lower layer of paper, the upper gas-resistant bubble layer and the lower gas-resistant bubble layer are connected type gas-resistant bubble units, the connected type The flame-retardant bubble unit is composed of a bott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com