Coaxial helicopter head, coaxial helicopter and using method of coaxial helicopter

A coaxial helicopter and main shaft technology, applied in the field of aircraft, can solve problems such as poor use effect, and achieve the effects of reasonable structure design, better overall use effect and compact mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

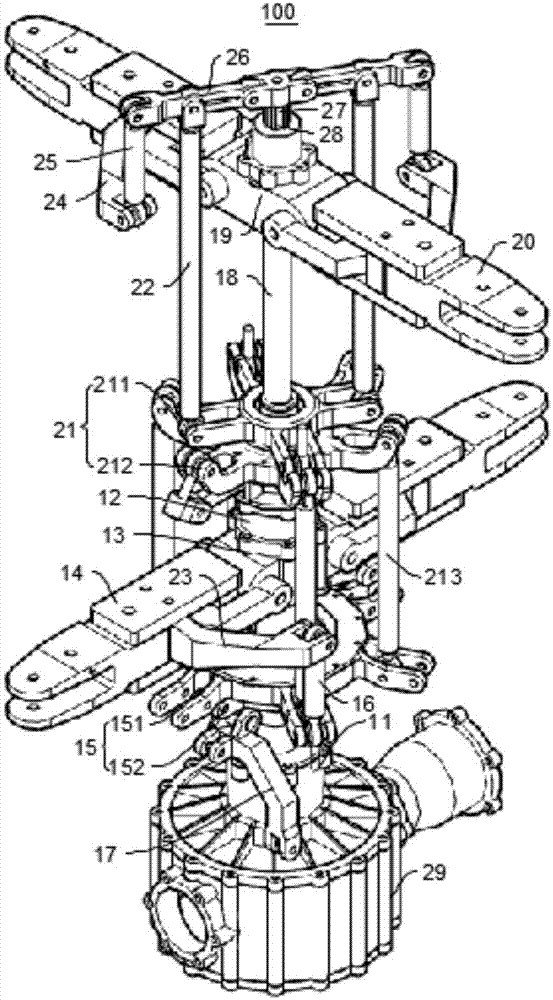

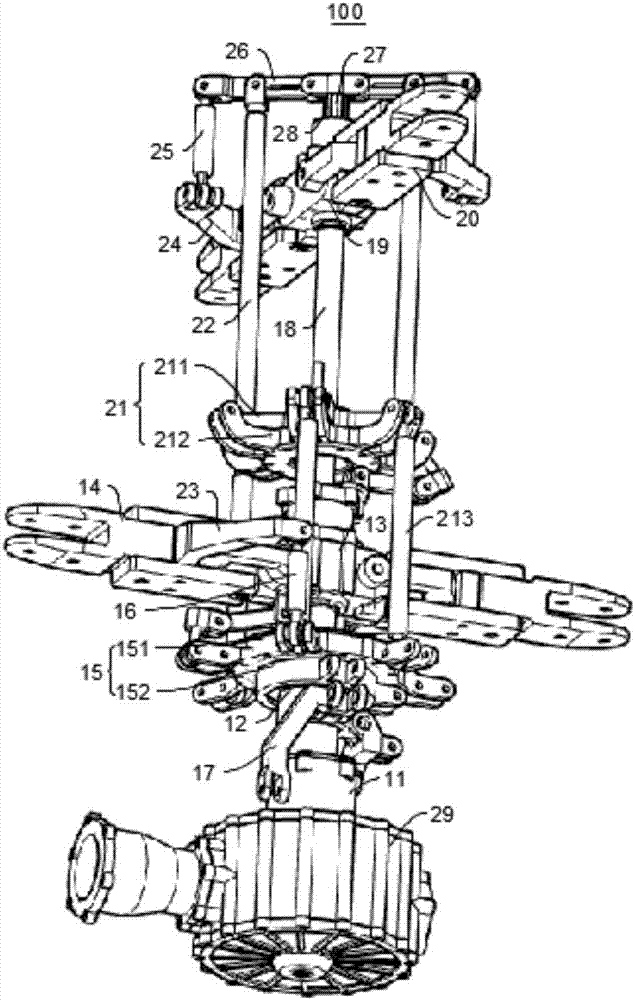

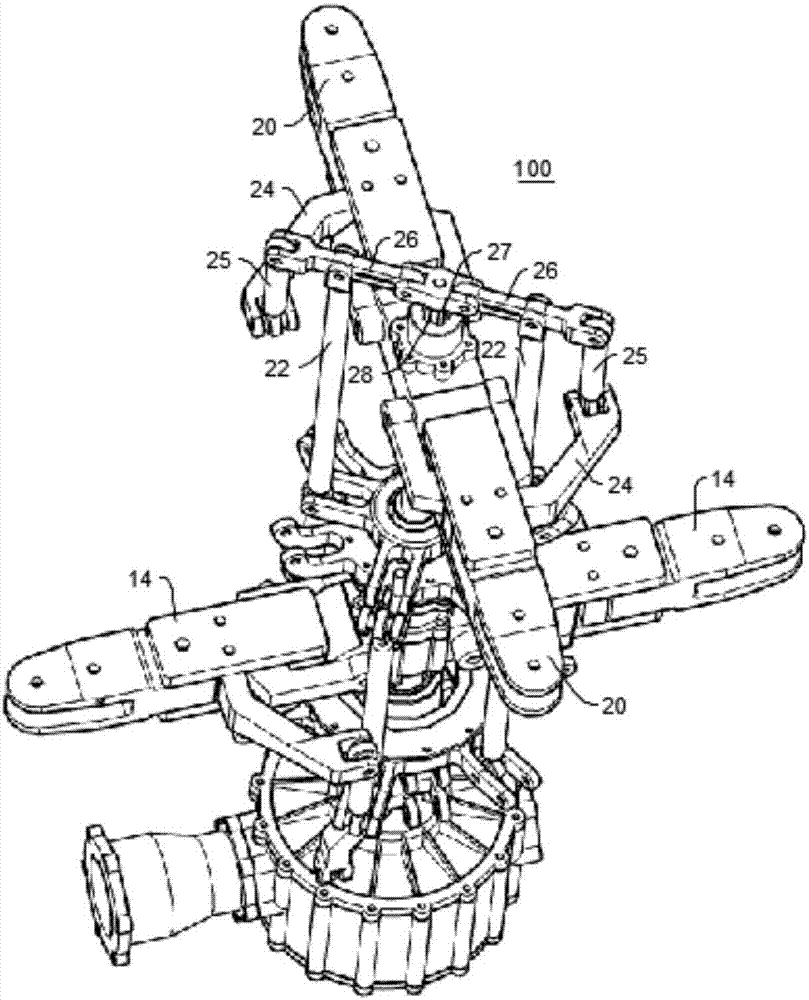

[0055] Please refer to Figure 1-Figure 4 , the present embodiment provides a coaxial helicopter head 100, which includes:

[0056] Rack 11;

[0057] The first main shaft 12, the first main shaft 12 is rotatably connected to the frame 11, the first main shaft 12 is used to connect with the clutch of the coaxial helicopter;

[0058] The first fixing part 13, the first fixing part 13 is connected with the first main shaft 12, and rotates with the rotation of the first main shaft 12;

[0059] The first rotor clamping part 14, the first rotor clamping part 14 is used to clamp the first rotor, the first rotor clamping part 14 is rotatably connected to the first fixing part 13, and the first rotor clamping part 14 The axis of rotation is perpendicular to the axis of rotation of the first main shaft 12, and the axis of rotation of the first rotor holder 14 extends in the length direction of the first rotor;

[0060] The first swash plate 15, the first swash plate 15 includes a fir...

Embodiment 2

[0098] This embodiment also provides a coaxial helicopter, which includes the above-mentioned coaxial helicopter head 100 , which has all the functions of the coaxial helicopter head 100 .

[0099] The structure of the coaxial helicopter head 100 can refer to Embodiment 1.

Embodiment 3

[0101] This embodiment also provides a method for using a coaxial helicopter, using the above-mentioned coaxial helicopter head 100, the method includes:

[0102] Control and manipulate the connecting piece 17 so that the second disc 152 controls the activity of the first disc 151;

[0103] The first disc 151 drives the first connecting member 16 to move;

[0104] The first connecting part 16 drives the first rotor clamping part 14 to rotate relative to the first fixing part 13;

[0105] The first main shaft 12 rotates and drives the first rotor holder 14 to rotate with the first main shaft 12;

[0106] The first disc 151 drives the fourth disc 212 to move through the second connecting member 213, and makes the fourth disc 212 control the third disc 211 to move;

[0107] The third disc 211 drives the third connecting part 22 to move and makes the second rotor clamping part 20 rotate relative to the second fixing part 19;

[0108] The second main shaft 18 rotates and drives ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com