Equipment and method for conveying solid materials through vacuum draught fan positive and negative pressure

A solid material, positive and negative pressure technology, applied in the direction of conveying bulk materials, conveyors, transportation and packaging, etc., can solve the problems of energy waste, small size of the feeding port, harmful to human body and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

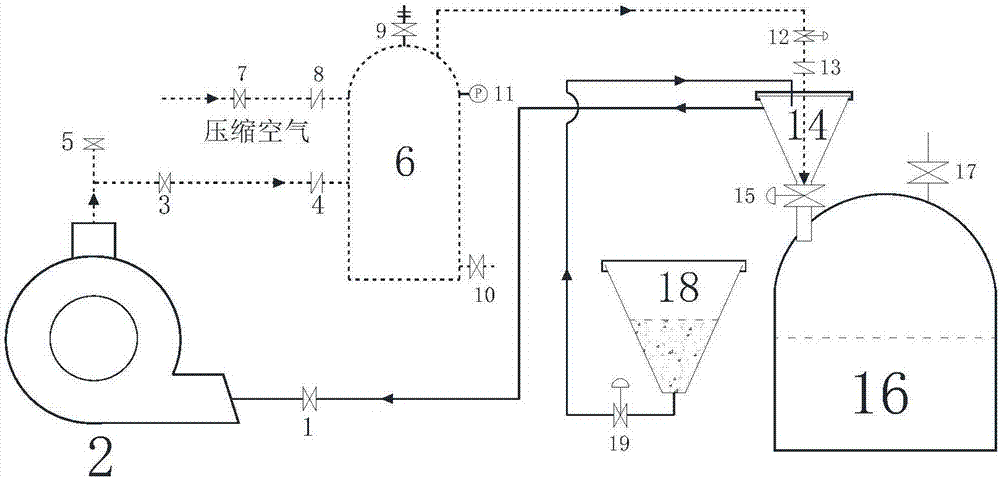

[0022] 1. First put the weighed solid material into the hopper, close the small hopper feeding pneumatic ball valve, start the fan, and the solid material will continuously enter the small hopper under negative pressure, and the fan will automatically stop after the set time. At the same time, the air is stored in the gas storage tank at the outlet of the fan, and at this time, the pneumatic ball valve at the outlet of the gas storage tank is closed;

[0023] 2. Open the small hopper feeding pneumatic ball valve to start feeding, and at the same time open the compressed air pneumatic ball valve to blow air into the small hopper. After the set time, the compressed air ball valve and the feeding ball valve will automatically close. After a feeding cycle is over, return The first step continues to feed until the end of the feed. process such as figure 1 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com