Pneumatic launching canister mechanism for loitering munition

A technology for launching cylinders and missiles, applied in the field of pneumatic launching cylinder mechanisms, can solve the problems of large acceleration overload peak value, complex cylinder processing, inability to adapt to kinematic performance requirements, etc., so as to avoid structural damage and reduce processing difficulty and cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] Below in conjunction with accompanying drawing, further illustrate the present invention with example.

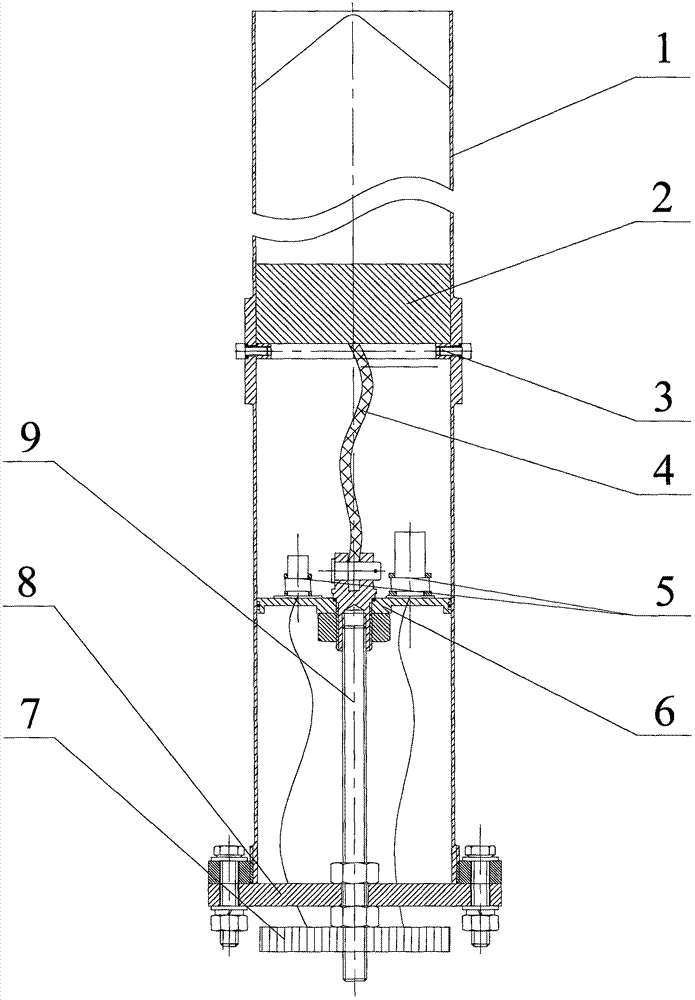

[0010] Such as figure 1 As shown, a pneumatic launching cylinder mechanism includes a cylinder body 1, a piston 2, a flow limiting orifice plate 3, a tether 4, a gas generator 5, an inner bottom plate 6, a controller 7, an outer bottom plate 8, and an adjusting screw 9.

[0011] Before launch, first install the flow-limiting orifice 3 with a suitable aperture, adjust the axial position of the inner bottom plate 6 with the screw thread of the adjustment screw 9 and fix it with the nut, adjust the length of the corresponding tether 4 and fix the two ends of the rope to the piston respectively. 2. On the bottom and the inner bottom plate 6, a start signal is provided to the controller 7, and the two gas generators 5 are started one after another and release the high-pressure gas. The high-pressure gas pushes the piston 2 and the loitering bomb through the flow-limiting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com