Detection tool for conic hole diameter detection

A technology of taper holes and measuring tools, which is applied in the field of parts processing, can solve the problems of measurement errors, cumbersome measurement, and low work efficiency, and achieve the effects of improving work efficiency, simple and convenient measurement, and avoiding random placement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

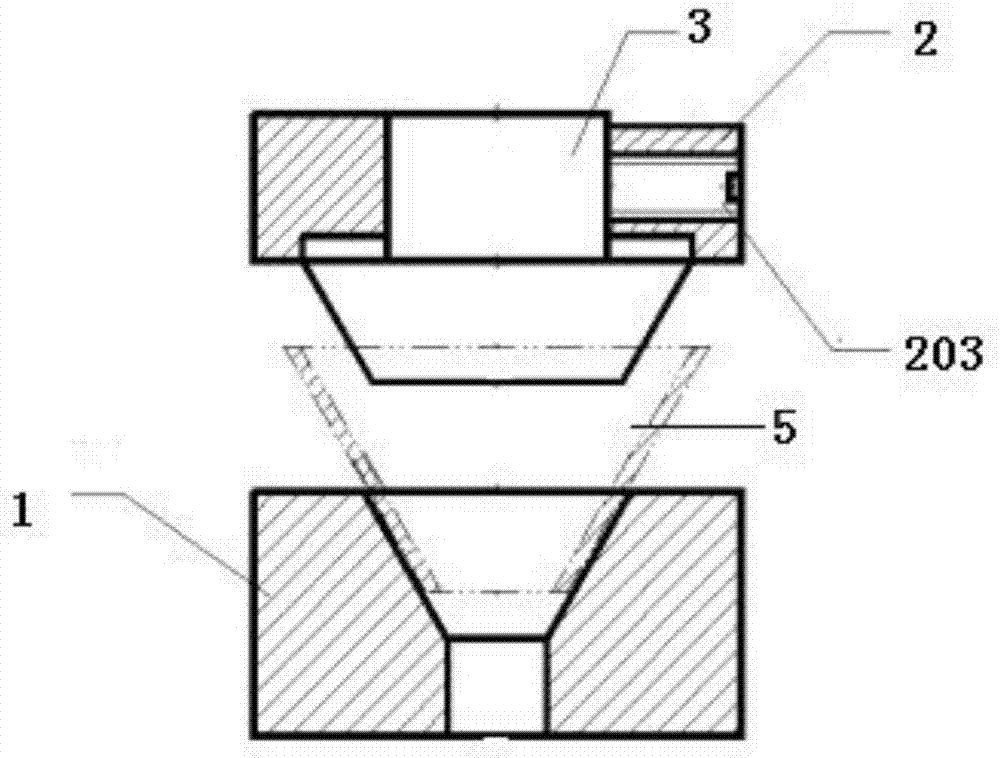

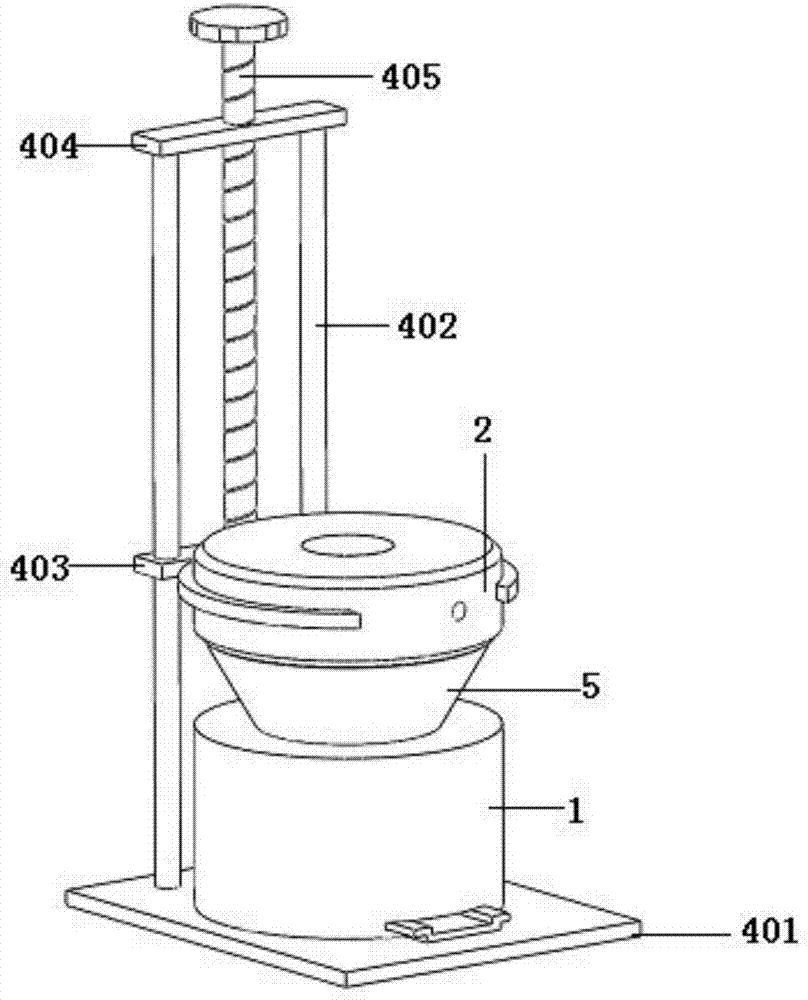

[0028] A measuring tool for measuring the diameter of a tapered hole, such as figure 1 , figure 2 As shown, it includes a pad cover 1, a sleeve 2, a measuring rod 3 and a bracket 4, the pad cover 1 and the sleeve 2 are installed on the bracket 4, and the measuring rod 3 is sleeved in the sleeve 2;

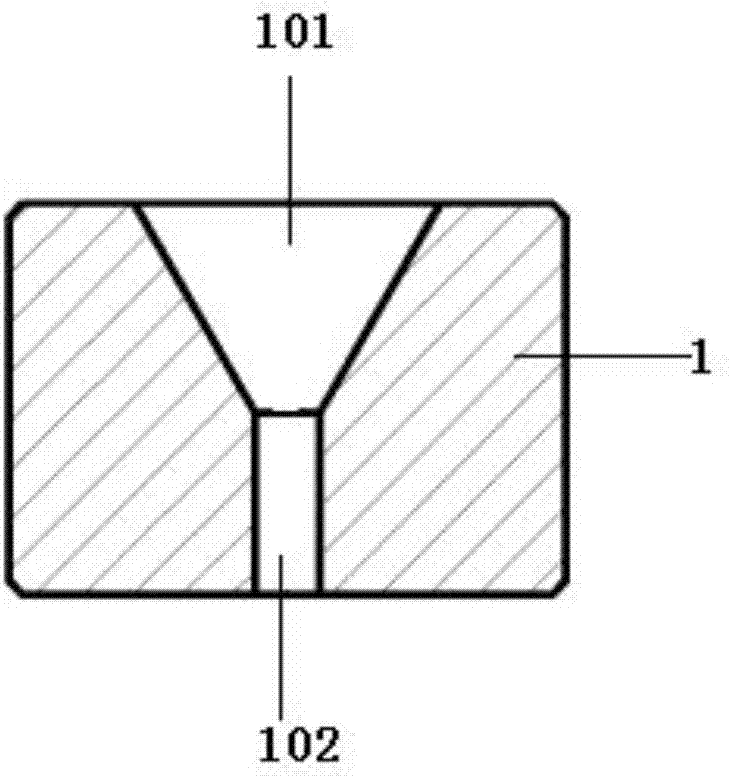

[0029] Such as image 3 and Figure 4 As shown, the surface of the pad cover 1 is provided with a tapered groove 101 along the axial direction, and the bottom surface of the tapered groove 101 is provided with a through hole 102, and the small diameter end of the detection cone 5 is placed and installed in the tapered groove 101. The taper of the tapered groove 101 is the same as the taper of the detection cone 5; the bottom surface of the pad cover 1 has a strip groove 103, and the two side walls corresponding to the strip groove 103 have a chute 104;

[0030] Such as Figure 5 As shown, the bottom surface of the sleeve 2 is provided with a circular groove 201, and the bottom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com