Concrete super-high pumping simulation verification apparatus and method

A simulation verification, ultra-high pumping technology, applied in the direction of measuring devices, material inspection products, flow characteristics, etc., can solve the problems that the scale and scale cannot be compared with pumping, and the influence of gravity is not considered.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

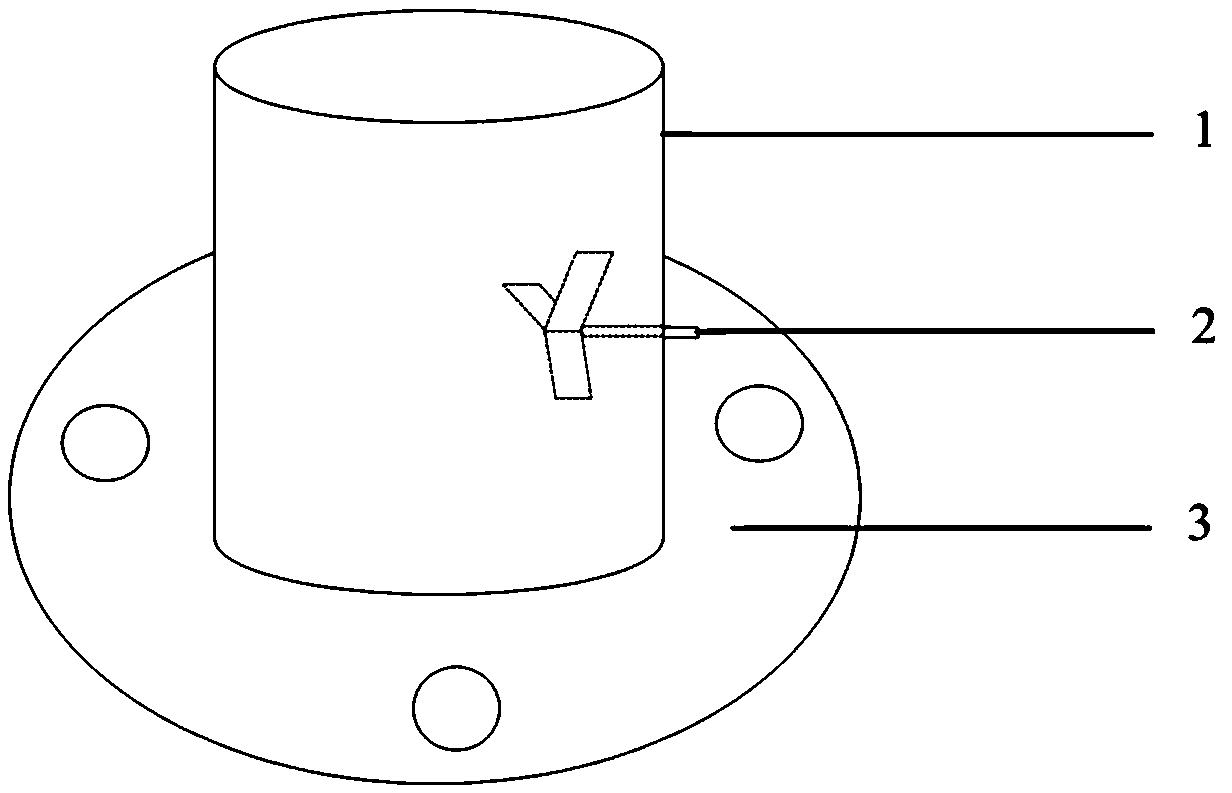

[0030] Combine below figure 1 , detailing the structural composition of the concrete ultra-high pumping simulation verification device of the present invention. A concrete ultra-high pumping simulation verification device, which includes a test pipeline 1 and a rotating impeller system 2, the test pipeline 1 is connected to the end of the concrete pump pipe through a flange 3; the rotating impeller system 2 is vertically installed on the test pipeline 1 Inner wall, the rotating impeller system 2 includes rotating blades, a rotating shaft and a measurement control system, the rotating blades are fixedly connected to the head end of the rotating shaft, the plane of the rotating blades is parallel to the main axis of the test pipe 1, and the rotating shaft is vertically fixed to the inner wall of the test pipe 1 , the tail end of the rotating shaft extends to the outer wall of the test pipe 1, and the measurement control system is fixedly connected to the end of the rotating shaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com