Hollow high-precision three-axis horizontal turntable in heavy load

A large-load, empty-height technology, applied in the direction of worktables, measuring devices, instruments, etc., can solve the problems of heavy weight, high cost, and low resonance frequency of turntables, reduce the difficulty of correction, use safe and reliable, and solve low precision Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The principles and features of the present invention will be described below with reference to the accompanying drawings. The examples are only used to explain the present invention, but not to limit the scope of the present invention.

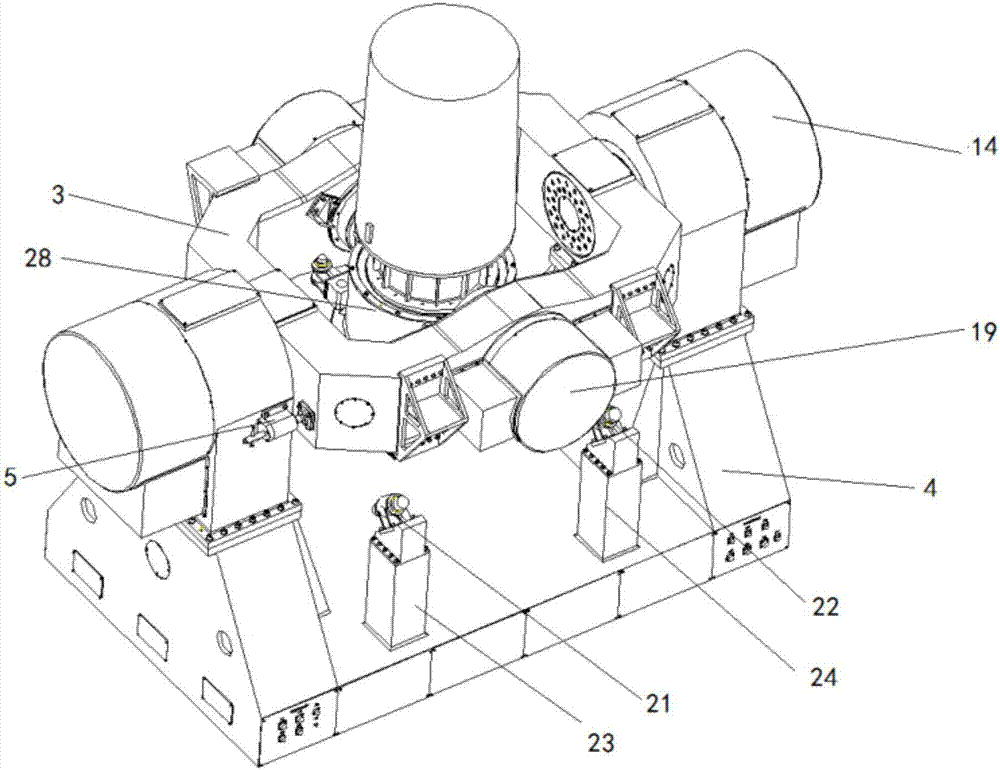

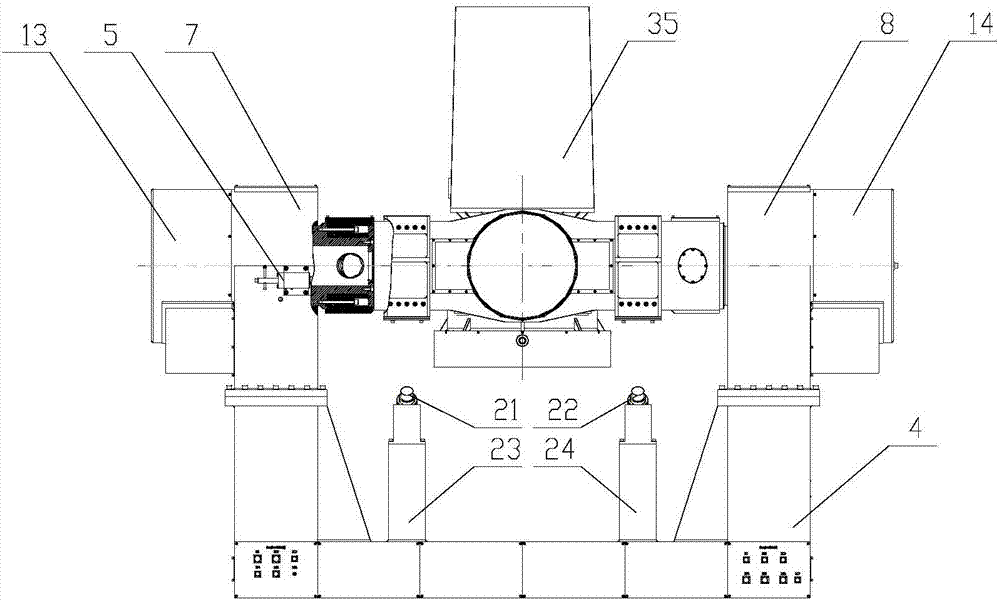

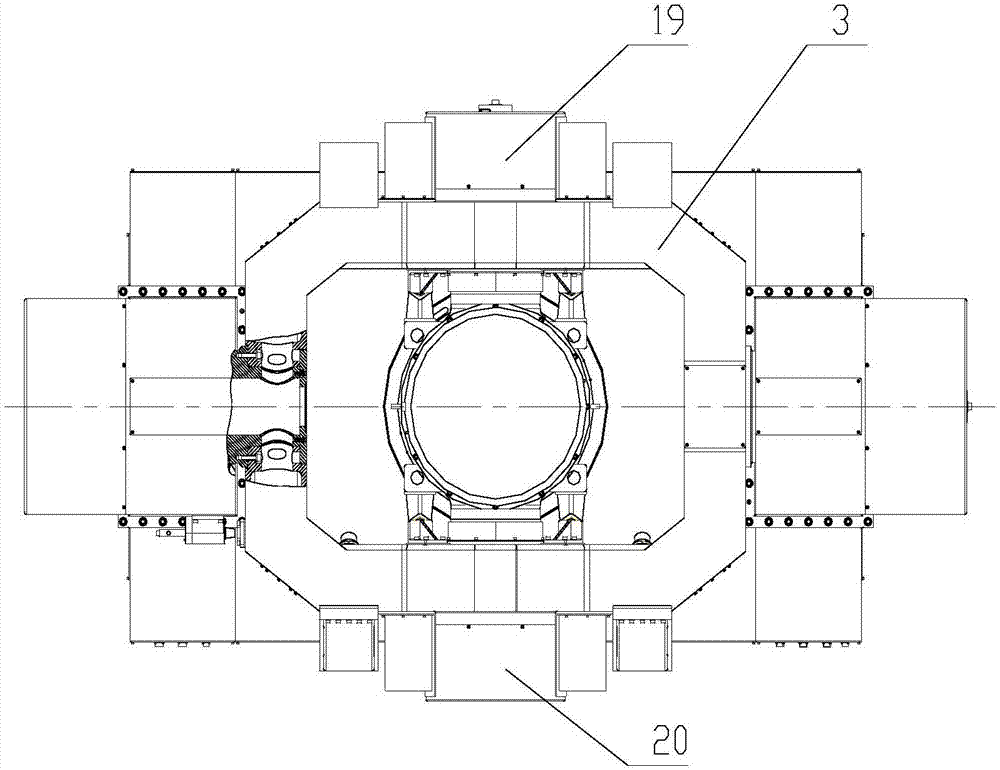

[0043] attached Figure 1-6A specific structure of a large-load inner hollow high-precision three-axis horizontal turntable is given, including: an angle encoder A1, a middle frame 3, an angle encoder B2, an inner frame 28, a circular grating 29, and a load mounting frame 30, Also includes: U-shaped base 4, outer frame bearing seat A7, outer frame bearing seat B8, outer frame torque motor A9, outer frame torque motor B10, outer frame shafting A11, outer frame shafting B12, paired angular contact ball bearings 31. Rotating shaft 32, lock nut 33, outer frame cover A13, outer frame cover B14, locking pin A5, outer frame buffer A21, outer frame buffer B22, outer frame buffer bracket A23, outer frame buffer bracket B24 , middle frame cover ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com