An Adaptive Feature Extraction Method for Weak Faults of Electromechanical Equipment

A technology of fault characteristics and extraction methods, applied in the direction of measuring devices, testing of mechanical components, testing of machine/structural components, etc., to achieve the effects of reducing boundary distortion, improving properties, and avoiding phase distortion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

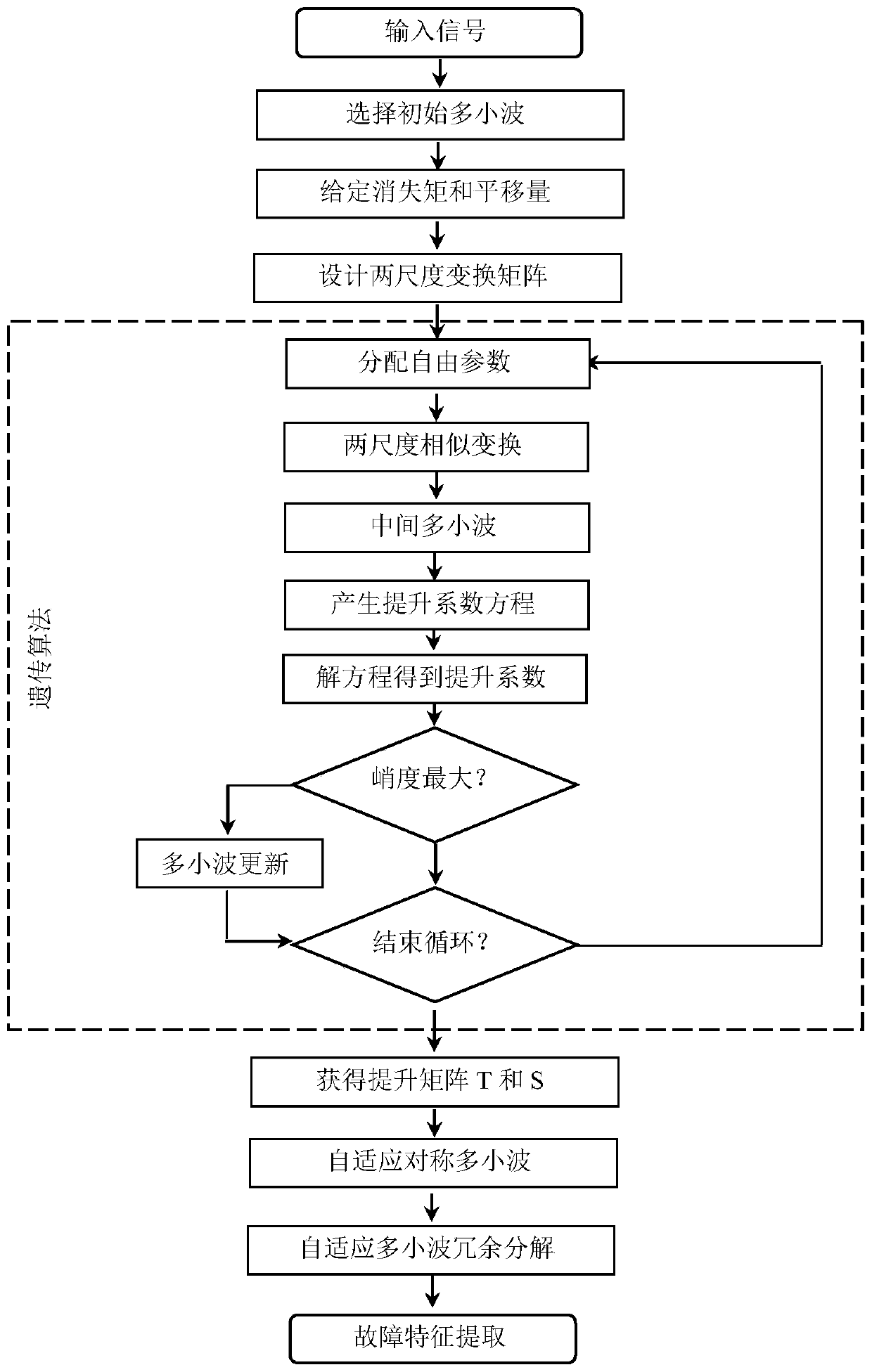

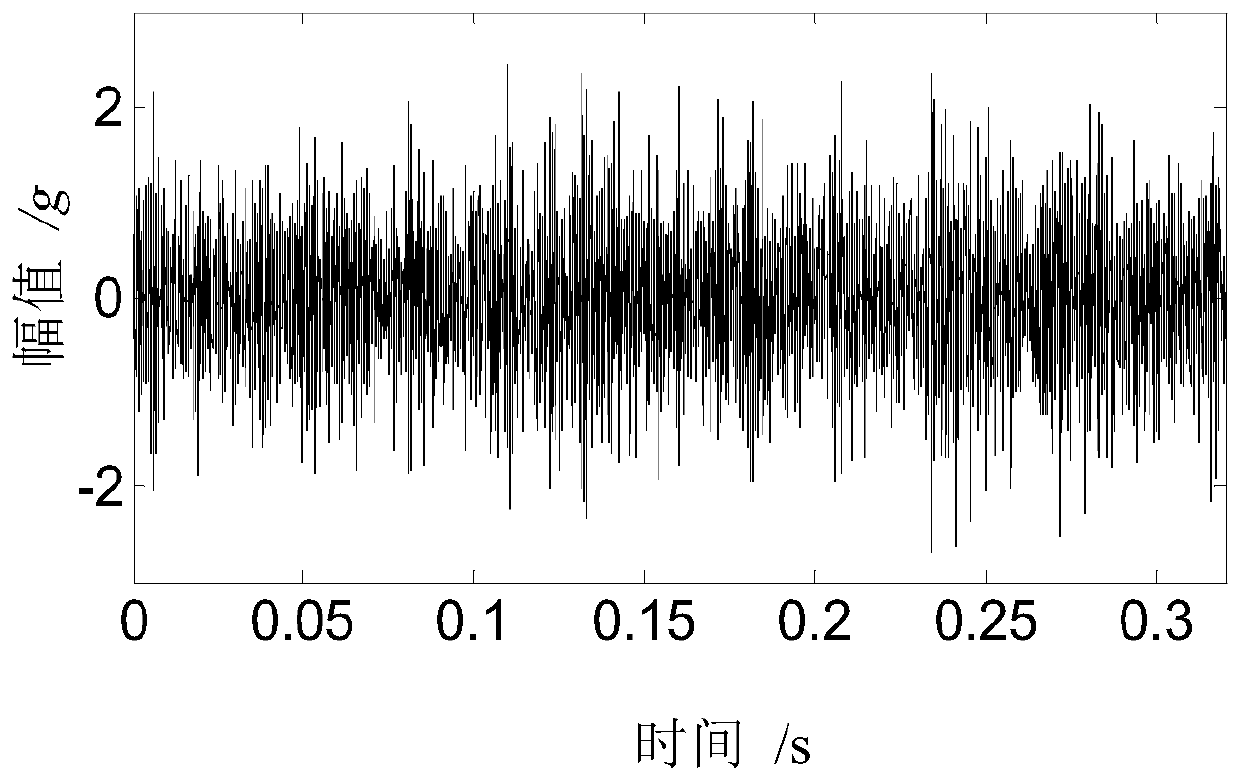

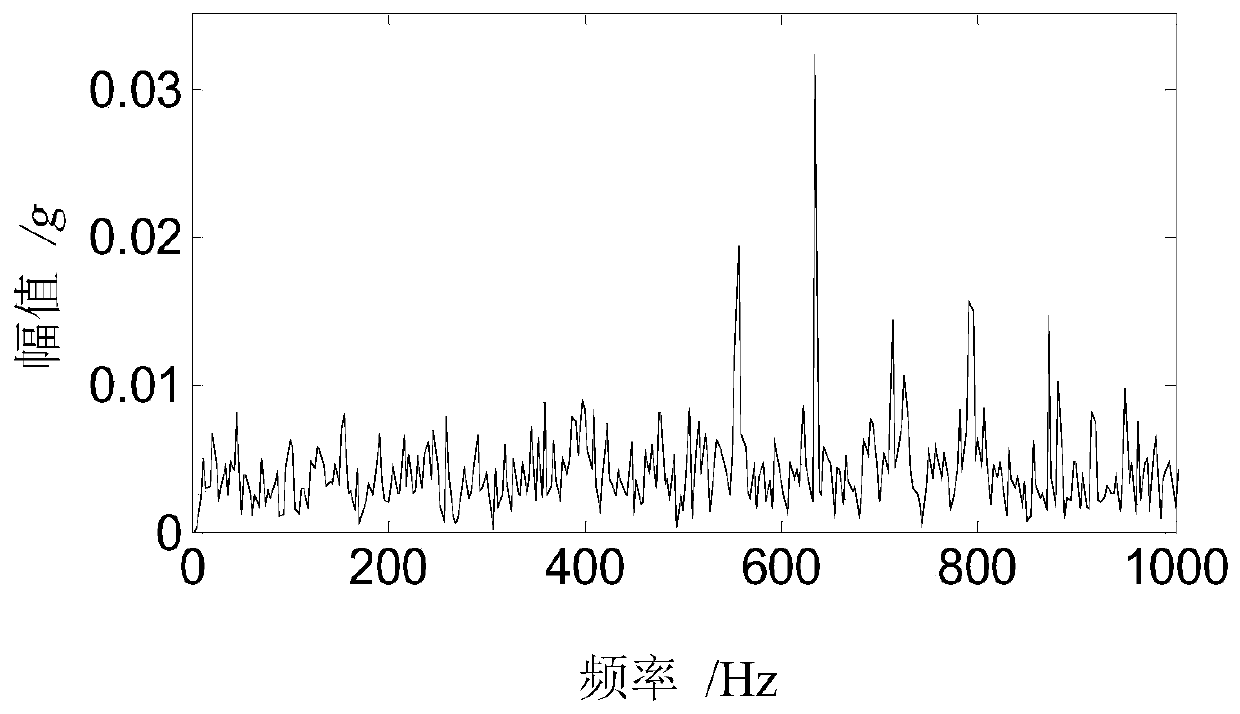

[0025] The present invention is based on the two-scale similarity transformation of multi-wavelets and the symmetrical lifting framework. It first collects vibration signals during the operation of mechanical equipment through vibration acceleration sensors; The approximation order of the function; then design the multi-wavelet lifting matrix that satisfies the symmetry condition to ensure the linear phase characteristics of the filter of the multi-wavelet basis function, avoid the phase distortion during signal decomposition and reconstruction and improve the boundary processing ability; by studying the similarity between the two scales Transformation and symmetric lifting frame multi-wavelet integration construction algorithm, design a multi-parameterized two-scale similar transformation control matrix and multi-wavelet symmetric lifting matrix that meet the constraints, and realize the multi-wavelet integration construction method; finally, based on the vibration signal, use ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com