On-line fluid viscosity detection device

A detection device and viscosity technology, applied in measurement devices, flow characteristics, instruments, etc., can solve the problems of complicated installation, affect the detection effect, and inability to obtain detection signals accurately, and achieve the effect of preventing frontal impact and high detection accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

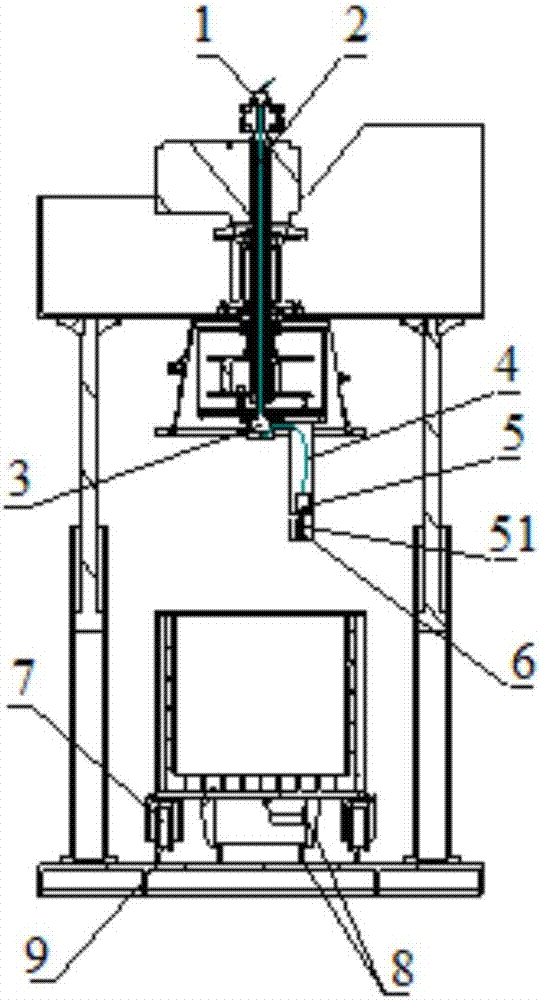

[0010] Including power-up slip ring 1, dedicated line routing hole 2, power-down slip ring 3, viscometer protective cover 4, and viscometer 5, among which the viscometer 5 is installed in the stirring mechanism to prevent the frontal impact of the material Viscometer protective cover 4 Inside, one end of the wire passing through the special line routing hole 2 is connected to the upper power slip ring 1, and the other end is connected to the lower power slip ring 3 to transmit signal power during continuous rotation.

[0011] The on-line viscometer probe 51 in the viscometer 5 is inserted into the viscometer probe protection cavity 6; the special line routing hole 2 is resistant to high temperature of 200°C; the special line routing hole 2 is installed in the planetary stirring mechanism that adopts revolution and rotation; the viscosity Meter protective cover 4 material is stainless steel. The reaction kettle located under the online fluid viscosity detection device is moved ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com