Virtual assembling demonstrating and teaching method based on Leap Motion

A technology of virtual assembly and teaching methods, applied in the field of virtual assembly, can solve the problems of not taking into account the versatility of mechanical products, and the fine motion capture of fingers is not accurate enough, so as to achieve the effect of enhancing human-computer interaction and good immersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

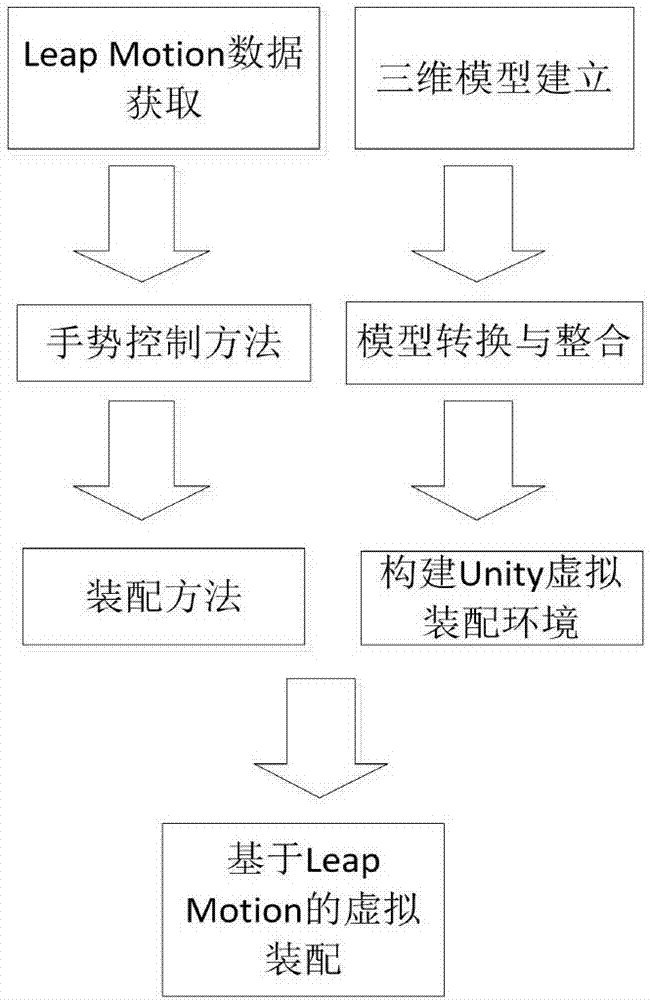

[0037] Such as figure 1 As shown, a virtual assembly teaching method based on Leap Motion includes the following steps:

[0038] Step 1, 3D modeling and correct assembly of the components of the assembly, follow the steps below:

[0039] Step 1-1, 3D modeling of components Use any commonly used CAD modeling software on the market, such as Proe, SolidWorks, etc., through the establishment of extrusion, rotation, boss, chamfer and hole features, use draft, array, Tools such as ribs, and the use of surface functions to build component models to ensure that the size and proportion of components are consistent;

[0040] Step 1-2, use the assembly function in the modeling software described in step 1-1 to correctly assemble the components to obtain the assembly model. After the assembly, check whether the components interfere. If there is interfer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com