Motor rotor iron core, motor rotor, motor and washing machine

A motor rotor and rotor core technology, which is applied in the fields of motors and washing machines, motor rotor cores, and motor rotors, can solve problems such as difficulty in ensuring the roundness of the iron core, different radial positions of permanent magnets, and uniformity of the motor air gap. Achieve the effect of preventing radial position difference and ensuring rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

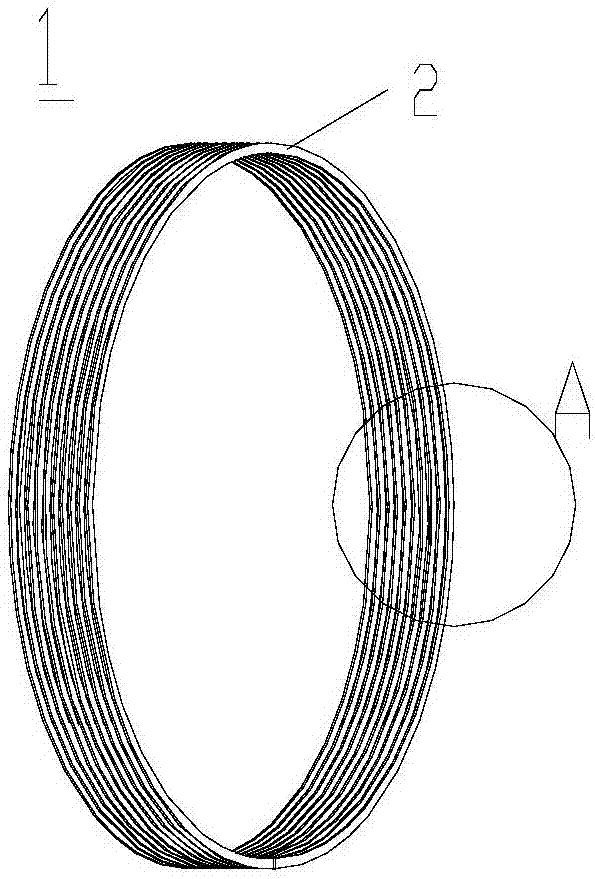

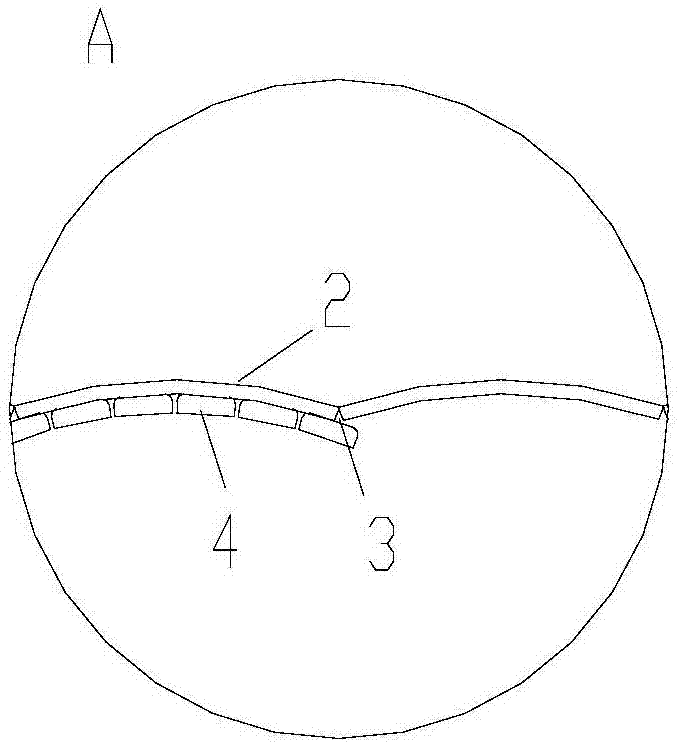

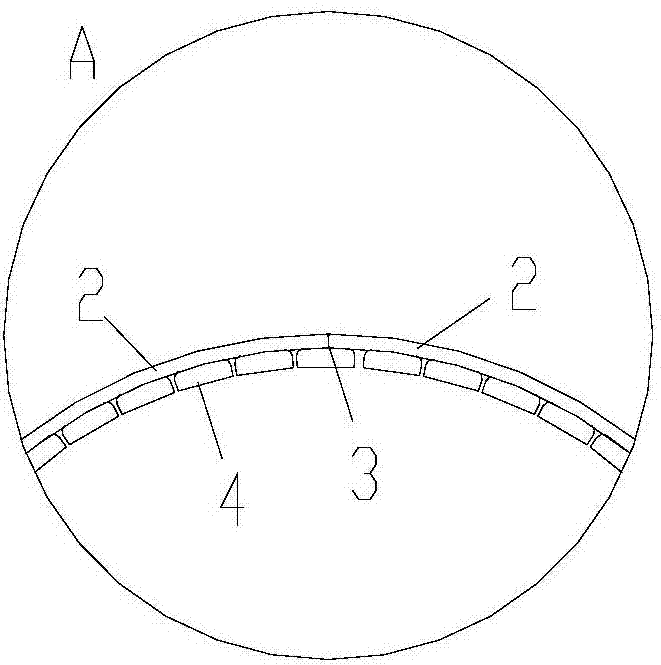

[0063] Such as Figure 1-2c As shown, the present invention provides a motor rotor iron core 1, which includes:

[0064] The rotor core 1 is formed by successively connecting and winding a plurality of strip-shaped punching sheets 2, and when the plurality of strip-shaped punching sheets 2 are unfolded, there is a notch between two adjacent strip-shaped punching sheets 2 3. To enable multiple segments of the strip-shaped punching sheet 2 to be bent to form a circular ring structure when wound to accommodate magnets (preferably permanent magnets) arranged in the circular ring structure.

[0065] The rotor core is formed by successively connecting and winding a plurality of strip-shaped punching sheets, and when the plurality of strip-shaped punching sheets are unfolded, there are notches between the two adjacent strip-shaped punching sheets, so that the When the strip punches are wound, they can be bent to form a circular ring structure to accommodate the magnets arranged in the cir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com