Engine support

An engine bracket and engine technology, which is applied in the direction of power plant, jet propulsion device, internal combustion propulsion device, etc., can solve problems such as the gap between the mounting bracket and the engine, the engine cannot work normally, and the engine generates vibration, so as to enhance the mechanical strength and improve the structure Tightness, the effect of improving the stability of the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

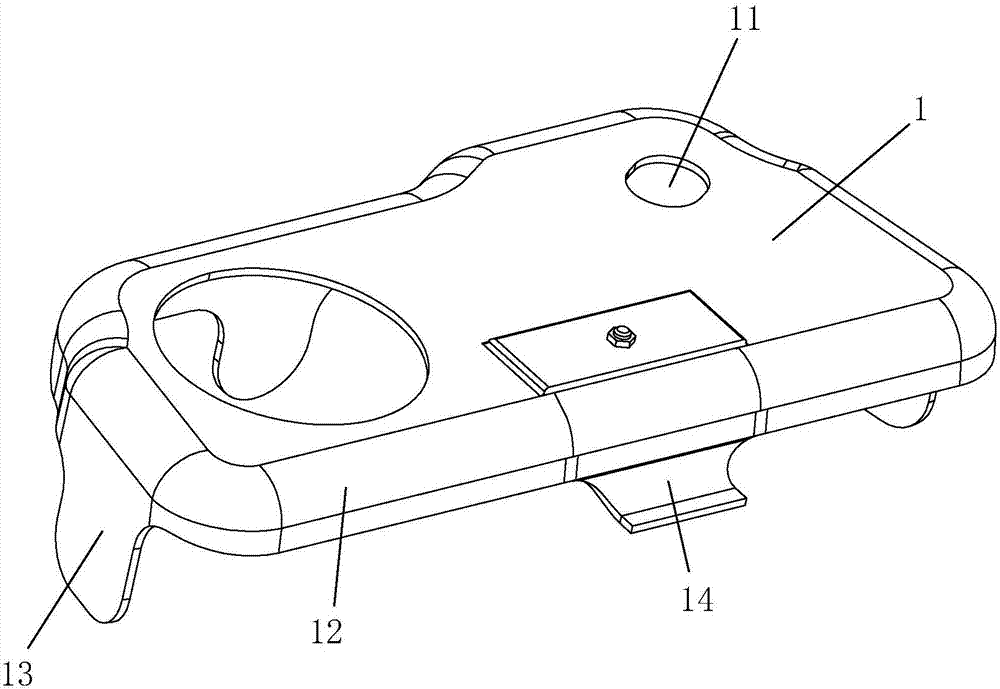

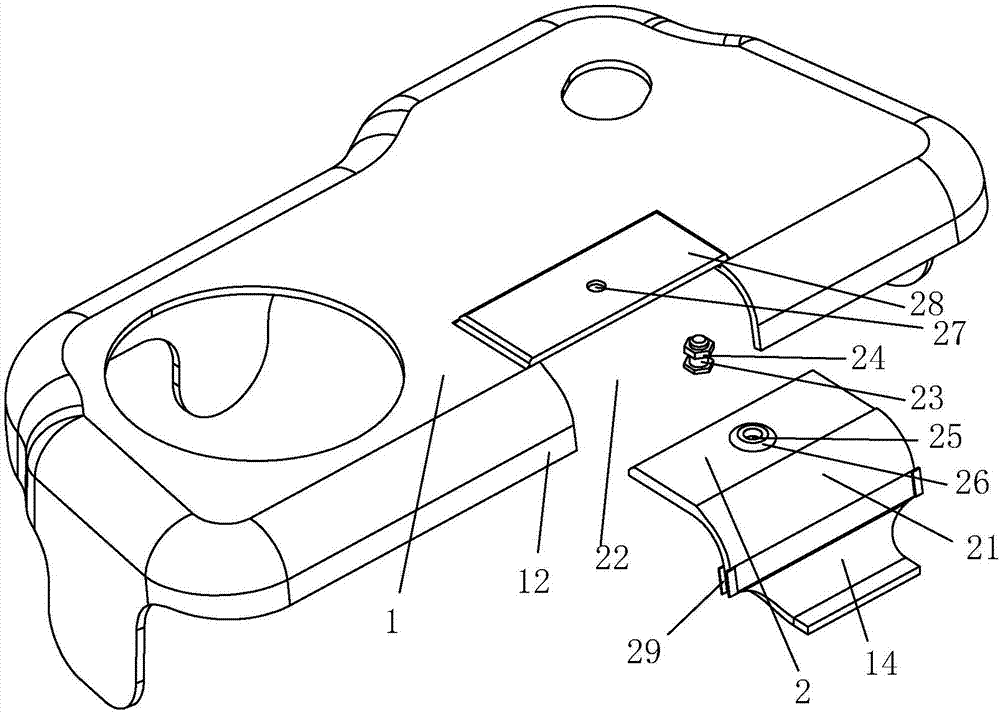

[0028] Example: such as figure 1 As shown, an engine bracket includes a main board 1, which is provided with several mounting holes 11 for matching with the engine, and the four end corners of the main board 1 are rounded to avoid scratches and reduce floor space. A retaining sleeve 12 extends downward from the periphery of the main board 1 , and the joint between the retaining sleeve 12 and the main board 1 is arranged in an arc shape along the width direction. The joints between the retaining sleeve 12 and the main board 1 are arc-shaped, and the thickness of the retaining sleeve 12 and the main board 1 is the same, so as to prevent the mechanical strength of the joint from being lower than that of the main board 1 and the retaining sleeve 12, so that when the bracket is impacted, the retaining sleeve 12 and the main board 1 The connection is easy to break.

[0029] like figure 1 As shown, there is a positioning piece 13 inserted into the engine extending from the retainin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com